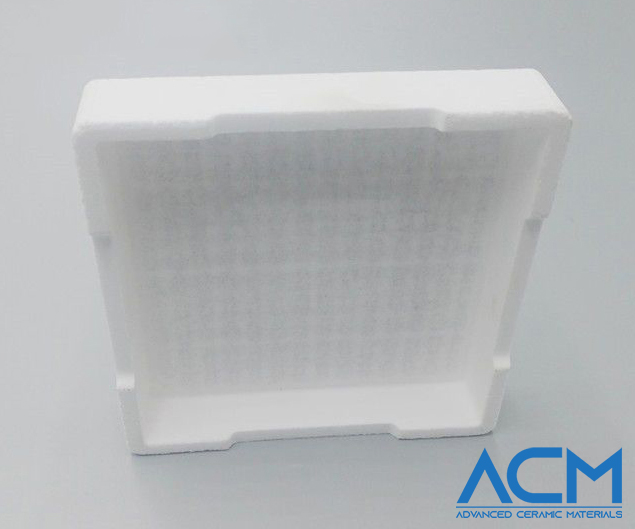

CM3926 Corundum Mullite Ceramic Saggar

- Catalog No. CM3926

- Material ZrO2

- Density 6.02g/cm3

- Size Customized

Datasheet

Inquiry

CM3926 Corundum Mullite Ceramic Saggar

Corundum Mullite Ceramic Saggar Description

Corundum Mullite Ceramic Saggar is usually larger and used to protect or support products during firing, for example in the glost or biscuit firing of tableware, for powder calcination, etc. These products can be made by semi-dry pressing, plastic pressing, and casting.

Corundum Mullite Ceramic Saggar Specifications

| Item | Units | Index |

| Temperature of usage | ℃ | ≤1400 |

| Bulk density | g/cm3 | ≥2.68 |

| Modulus of rupture (at room temp) | MPa | ≥50 |

| (1300℃) Modules of rupture | MPa | ≥30 |

| Open porosity | % | <25 |

| (1300℃)Thermal expansion coefficient | X10-8K-1 | 6.5 |

| SiC percent | % | 60 |

Corundum Mullite Ceramic Saggar Applications

In the glost or biscuit firing of tableware, or for powder calcination, etc.

Corundum Mullite Ceramic Saggar Packaging

Our Corundum Mullite Ceramic Saggar is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Request a Quote

-

Attachment (Optional)

No file chosen