CY2404 Sapphire Crystal Substrate, Al2O3

- Catalog No. CY2404

- Size Dia.1’’x 0.5mm; Dia.2’ x 1mm; 10 x10 x0.5mm; 5×5×0.5mm

- Purity ≥99.95%

- Thickness 0.5mm; 1mm

- Molecular Formula Al2O3

- Crystal Class Hexagonal System

Datasheet

Inquiry

CY2404 Sapphire Crystal Substrate, Al2O3

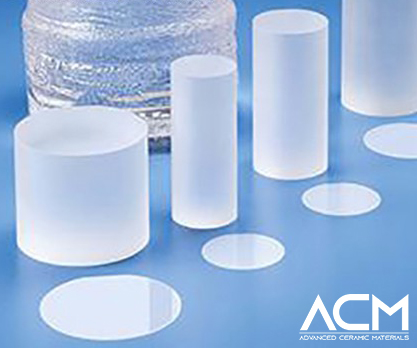

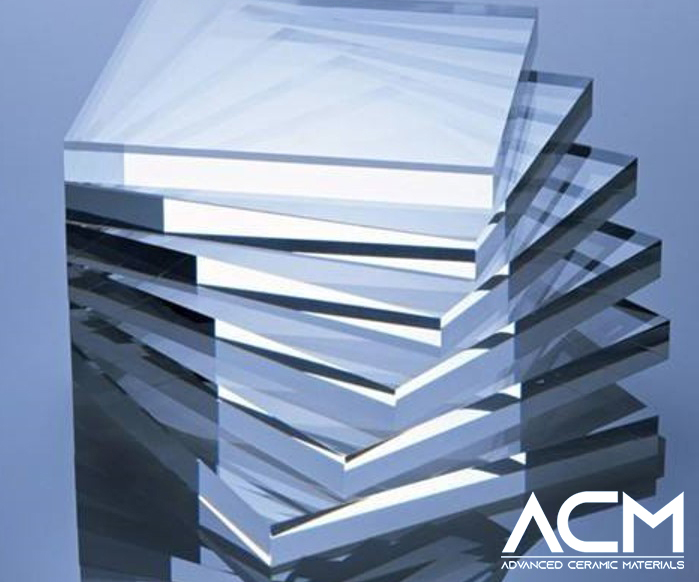

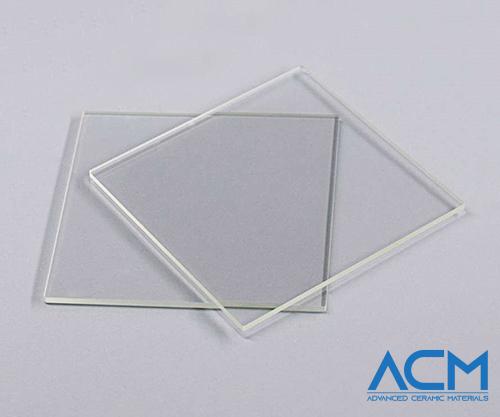

Sapphire Crystal Substrate Description

Sapphire crystal substrate has good thermal characteristics, excellent electrical and dielectric properties, and is resistant to chemical corrosion. It is resistant to high temperatures and has good thermal conductivity, high hardness, infrared transmission, and chemical stability. It is widely used in high-temperature resistant infrared window materials, III-V nitrides, and various epitaxial film substrate materials.

Sapphire Crystal Substrate Specifications

|

Crystal Class |

Hexagonal system |

|

Lattice Constants |

a=4.785, c=12.991 |

|

Density |

3.98g/cm3 |

|

Melting Point |

2040 °C |

|

Hardness |

9(mohs) |

|

Elastic Coefficient |

C11= 495; C12=160; C33= 497; C44= 146; C13= 115; C14= 23 GPa |

|

Thermal Conductivity |

46.06 @ 0?oC, 25.12 @ 100?oC, 12.56 @ 400?oC ( W/(m.K)?) |

|

Thermal?Expansion |

7.5 x 10-6 /℃ |

|

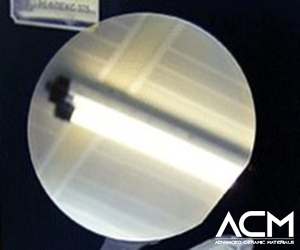

Standard Orientation |

<0001>、<11-20>、<1-102>、<10-10>±0.2? |

|

Standard Size |

?5x5mm, 10x10mm, Dia1"(25.4mm), Dia2"(50.8mm) Or customized. |

|

Standard Thickness |

0.5mm, 1.0mm, 2.0mm, 5.0mm |

|

Dielectric Constant |

~9.4@?300K at A-axis?~11.58@?300K at C-axis |

|

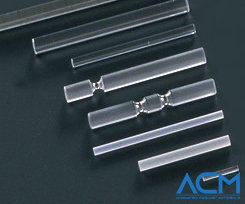

Polishing |

Single side polished or Double side polished |

Sapphire Crystal Substrate Applications

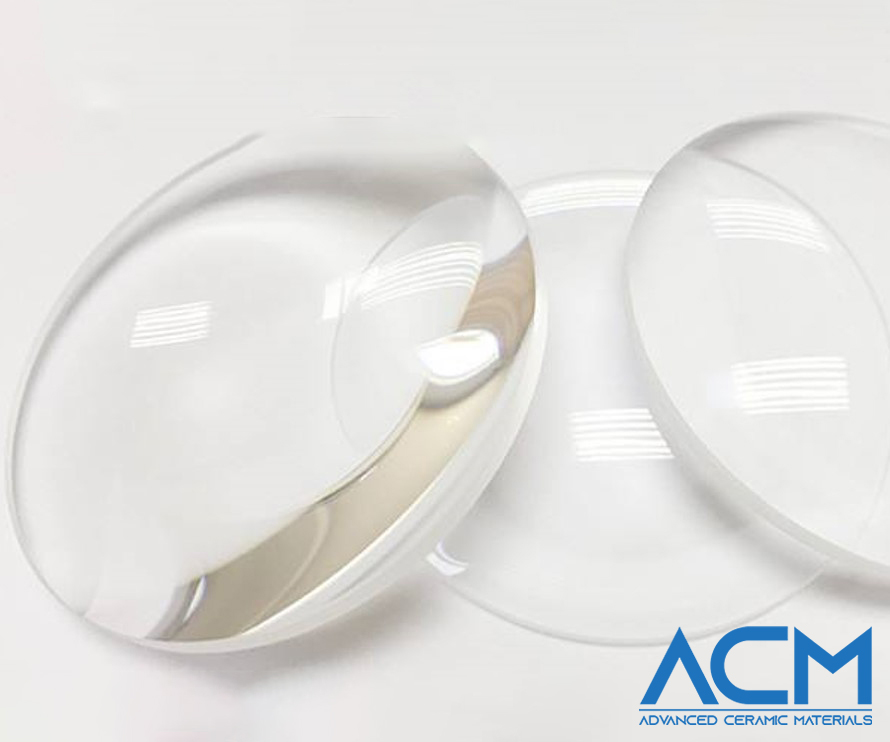

Sapphire Crystal Substrates are used in the following applications:

- Sapphire substrates: IR Detectors; microwave integrated circuits;

- Aerospace: withstand high heat, windows, countermeasures lamps;

- Medical: surgical systems, contact tips for various surgical laser applications, endoscope lenses;

- Watch industry.

Request a Quote

-

Attachment (Optional)

No file chosen