Titanium Dioxide Ceramics

Titanium dioxide ceramics refer to ceramics that incorporate titanium dioxide (TiO2) as a key component in their composition. Titanium dioxide is a white pigment widely used in various industries, including ceramics, due to its excellent opacifying and whitening properties. It is a versatile material with good chemical stability, high refractive index, and UV-blocking capabilities.

In the context of ceramics, titanium dioxide can be added to the ceramic matrix to achieve specific properties or characteristics. Some common applications and features of titanium dioxide ceramics include:

- Whiteness and Opacity

- UV Protection

- Catalytic Activity

- Electrical Properties

- Dielectric Properties

- Biocompatibility

Titanium Dioxide Ceramics Properties

-

Whiteness and Opacity: Titanium dioxide is widely recognized for its ability to impart a bright white color and excellent opacity to materials. In ceramics, this property is essential for achieving vibrant and opaque surfaces.

-

UV Resistance: Titanium dioxide is known for its UV-blocking capabilities. Ceramics incorporating TiO2 can resist degradation caused by exposure to ultraviolet radiation, making them suitable for outdoor applications.

-

Photocatalytic Activity: Certain forms of titanium dioxide exhibit photocatalytic activity, which means they can initiate chemical reactions when exposed to light. This property is utilized in self-cleaning ceramics, where contaminants are broken down under the influence of sunlight.

-

Biocompatibility: Titanium dioxide is generally considered biocompatible, making TiO2 ceramics suitable for use in biomedical and dental applications. They may be used in implants, prosthetics, and dental materials.

-

Dielectric Properties: Some titanium dioxide ceramics exhibit excellent dielectric properties, which are crucial in applications such as the manufacturing of capacitors and other electronic components.

-

Electrical Conductivity: Depending on the specific composition and processing, titanium dioxide ceramics can have varying levels of electrical conductivity, making them useful in electronic and semiconductor devices.

Titanium Dioxide Ceramics Applications

-

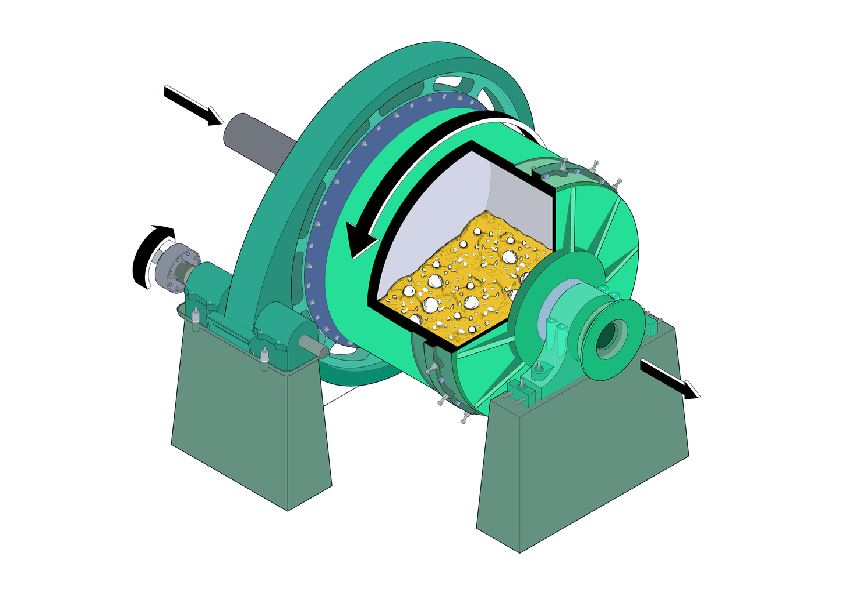

Ceramic Pigments: Titanium dioxide ceramics are commonly used as pigments in the ceramic industry to achieve bright white colors and opacity in glazes and ceramic bodies.

-

Tiles and Sanitaryware: TiO2 ceramics find extensive use in the production of tiles and sanitaryware due to their ability to provide a clean and bright appearance. The UV resistance is also beneficial for outdoor applications.

-

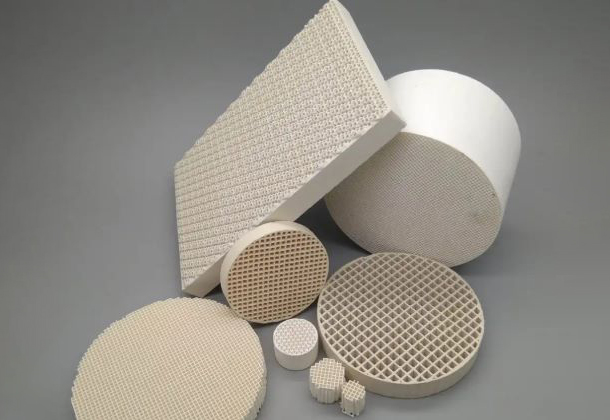

Catalysis: Photocatalytic titanium dioxide ceramics are used in applications where the breakdown of organic contaminants is desired, such as in self-cleaning surfaces for buildings, automotive coatings, and air purification systems.

-

Electronics: Titanium dioxide ceramics with appropriate electrical properties are employed in electronic components like capacitors and varistors.

-

Biomedical Devices: Biocompatible titanium dioxide ceramics are used in the manufacturing of biomedical implants, prosthetics, and dental materials.

-

Solar Cells: Titanium dioxide is used in the production of dye-sensitized solar cells (DSSCs) due to its photocatalytic properties.

-

Ceramic Coatings: Titanium dioxide may be included in ceramic coatings to enhance their UV resistance and provide additional functionalities such as self-cleaning properties.

Your Titanium Dioxide Ceramics Supplier

Advanced Ceramic Materials is a leading supplier of titanium dioxide ceramic products of the highest quality for a wide range of applications. We are happy to provide advice on materials, design, and application. Feel free to contact us for any questions about titanium dioxide or other ceramic materials that are not listed on the website.

| Chemical Formula | TiO2 |

| Mechanical | |

| Density | 3.84~4.23 g/cm3 |

| Hardness | 9.3-10.3 GPa |

| Modulus of Elasticity | 230-290 GPa |

| Flexural Strength | 50-100 MPa |

| Compressive Strength | 1000 MPa |

| Poisson's Ratio | 0.27-0.30 |

| Fracture Toughness | 2-3 MPa m½ |

| Electrical | |

| Dielectric Strength | 8-10 MV/m |

| Dielectric Constant | 20-100 |

| Volume Resistivity | 10^10 to 10^14 Ω·m |

| Thermal | |

| Coefficient of Thermal Expansion | 8.4-9.2 10^-6 /°C |

| Thermal Conductivity | 4 W/(m*K) |

| Specific Heat | 0.52 J/g·K |

| Shock Resistance | - |

| Maximum Working Temperature | 500-1000℃ |