Do you have any questions? Email Us

[email protected]

PBN Crucibles for Precision Application

Pyrolytic Boron Nitride Crucible can withstand high temperatures in a high vacuum environment. It has excellent thermal conductivity, corrosion resistance, and electrical resistance.

READ MORE >

ZR6073 Composite Zirconia Bead

Composite Zirconia Bead Overview

Composite Zirconia Beads are crafted from premium zirconia and alumina raw materials, using a titration rolling process followed by high-temperature sintering to achieve phase formation. These beads feature uniformly toughened zirconia grains, which enhance their hardness and minimize the occurrence of irregular shapes. Their excellent sphericity and medium-to-high density contribute to improved grinding efficiency. In various applications, Composite Zirconia Beads offer a cost-effective alternative to pure zirconia beads while maintaining high performance.

Composite Zirconia Bead Specification

|

Specific Gravity |

>5.3kg/dm3 |

|

Bulk Density |

>3.2kg/L |

|

Mohs Hardness |

>8.5 |

|

Vickers hardness |

1050kg/mm2 |

|

Compressive strength |

1600N(2mm) |

|

Sphericity |

96% |

Chemical Composition

|

Composition |

ZrO2+Y2O3 |

Al2O3 |

SiO2 |

Fe2O3 |

Na2O |

|

Wt% |

90 |

8 |

2 |

<0.02 |

<0.02 |

Specification

|

Model |

Diameter (φ) mm |

|

NZA6 |

0.6~0.8 |

|

NZA8 |

0.8~1.0 |

|

NZA10 |

1.0~1.2 |

|

NZA12 |

1.2~1.4 |

|

NZA14 |

1.4~1.6 |

|

NZA16 |

1.6~1.8 |

|

NZA18 |

1.8~2.0 |

|

NZA22 |

2.2~2.5 |

|

NZA25 |

2.5~2.8 |

|

NZA28 |

2.8~3.2 |

|

NZA32 |

3.2~3.5 |

*Sizes can be tailored to meet specific customer requirements.

Composite Zirconia Bead Applications

Pesticides and Fertilizers: Ideal for suspensions such as herbicides, insecticides, fungicides, and other agricultural products.

Paint and Coating Industry: Used for efficient grinding in the production of paints and coatings.

Liquid Packaging Inks: Ensures fine dispersion and uniform consistency in liquid packaging inks.

Non-Metallic Minerals: Suitable for the grinding and processing of non-metallic mineral materials.

New Energy Battery Materials: Applied in the preparation of materials for new energy batteries.

Composite Zirconia Bead Packing

25kg per drum, packaged in composite woven bags or drums.

Related Articles

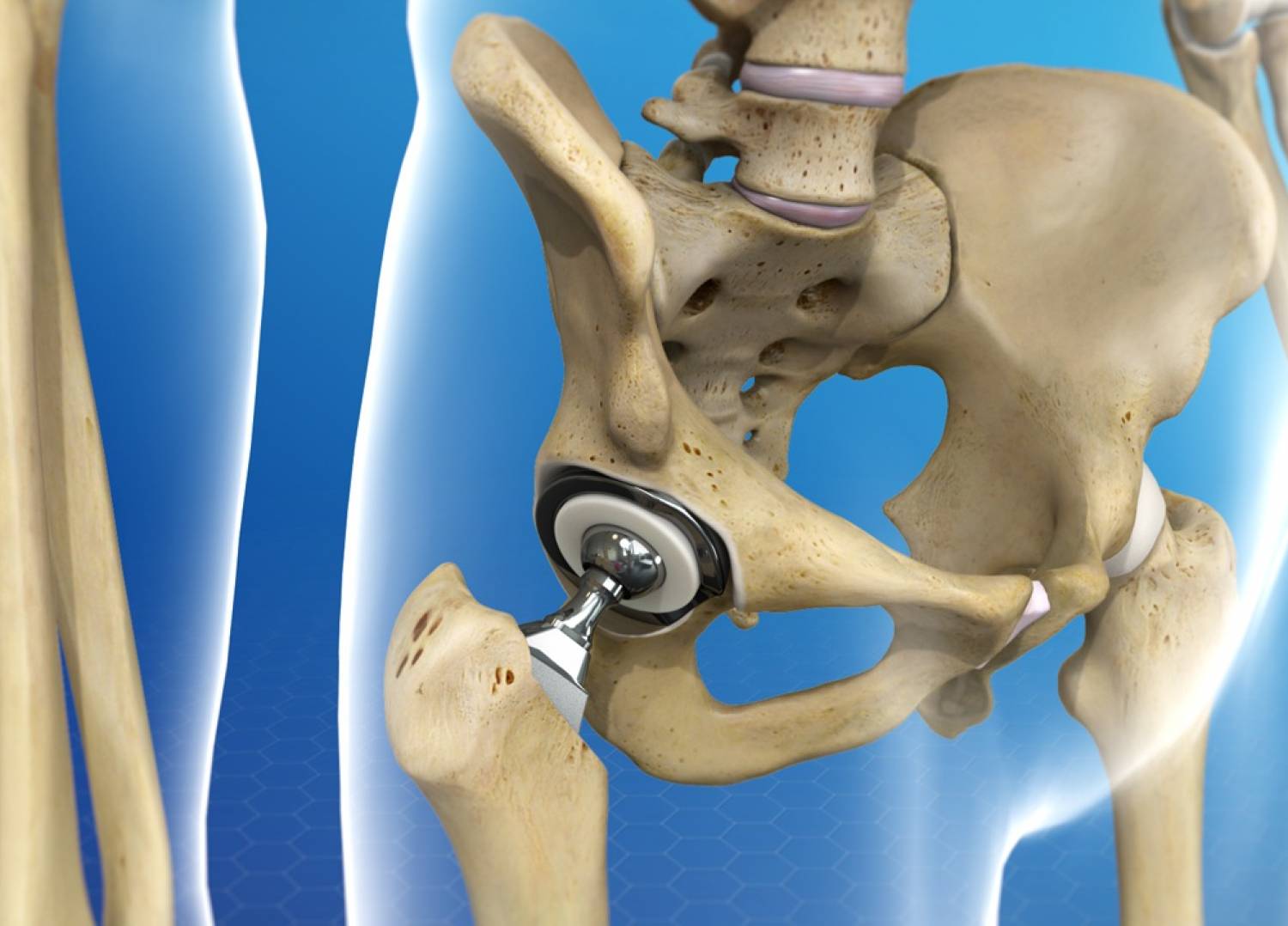

Zirconia Ceramics Application in Medical Field

Zirconia ceramics is now popular in the field of medical hard tissue repaired because of its dense texture, abrasion resistance, smooth surface, good biocompatibility and chemical stability.zirconia

READ MORE>

Zirconia Ceramics For Crown Implants Application

Compared to other all-ceramic systems, converted toughened zirconia ceramics is a good alternative in different clinical situations. The following advantages of zirconia ceramics explain why zirconia crowns are becoming more popular.

READ MORE>

Zirconia Ceramic Definition & Application Fields

Zirconia ceramics are high-grade industrial ceramic materials made of zirconia (ZrO2), which are chemically inert and highly heat-expandable.

READ MORE>

What Is Zirconia Ceramic Used For?

Zirconia ceramics are versatile materials known for their exceptional properties such as high-temperature resistance, electrical insulation, and wear resistance.

READ MORE>

Request a Quote

-

Attachment (Optional)

No file chosen

I would like to join the mailing list to receive updates from Advanced Ceramic Materials .

*e-mail address with your company's domain name is preferred. Otherwise, we may not be able to process your inquiry.

Tel : (949) 407-8904

Address : 23661 Birtcher Dr. Lake Forest, CA 92630 U.S.A.

Main Products

Useful Links

Featured Posts

Search

Copyright © 1994-2025 Advanced Ceramic Materials owned by Oceania International LLC, All Rights Reserved.