ZR6136 Zirconia Corundum Brick

- Catalog No. ZR6136

- Material Al2O3, ZrO2, SiO2

- Bulk Density 3.5-3.9 g/cm3

- Content ZrO2: ≤16%

- Max Working Temp. 1400 ℃

Inquiry

ZR6136 Zirconia Corundum Brick

Zirconia Corundum Brick Overview

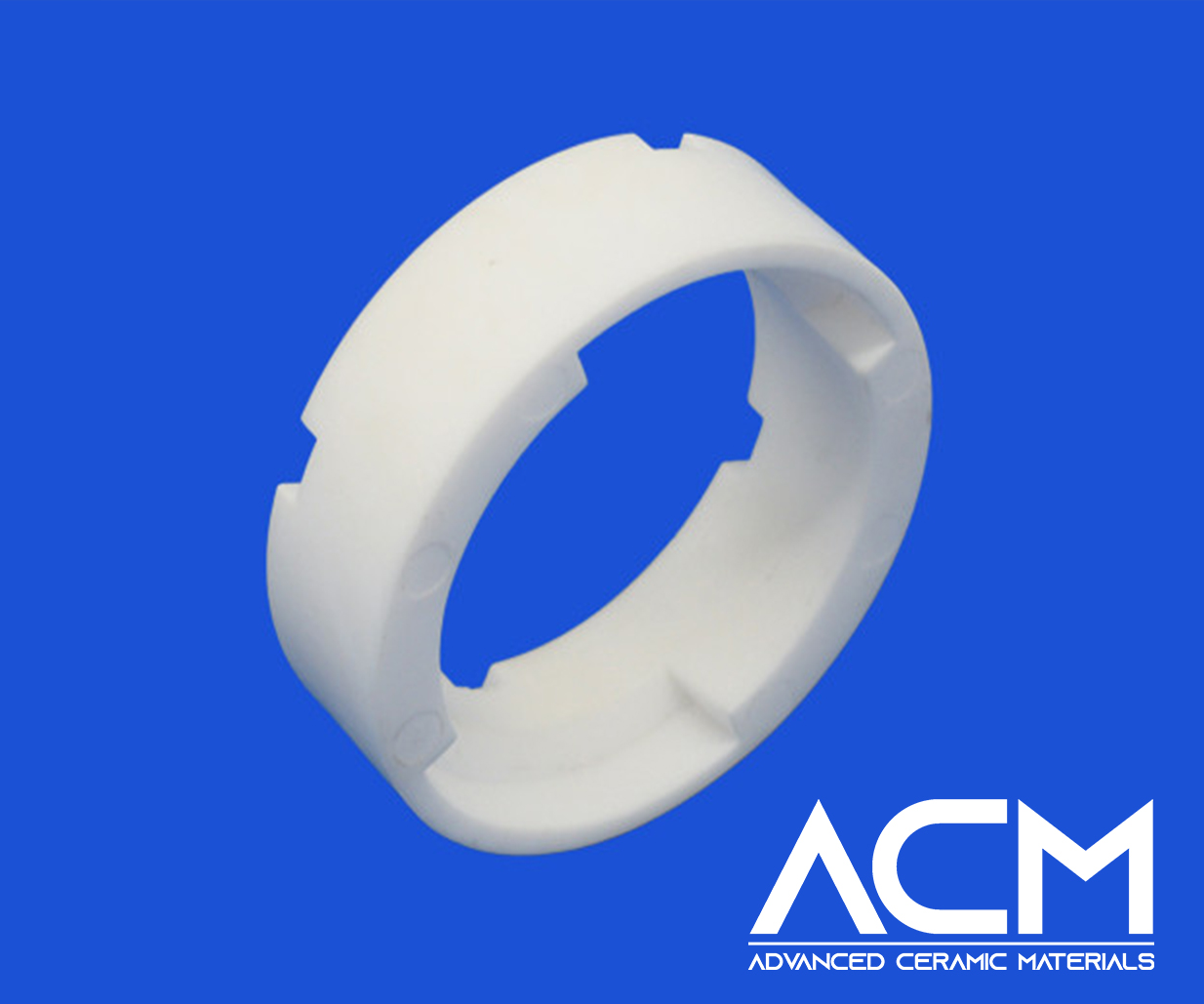

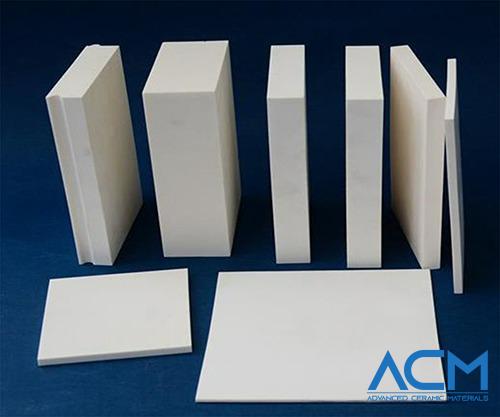

Zirconia Corundum Brick, commonly known as AZS Brick (Alumina-Zirconia-Silica Brick), is a high-performance refractory material made from a combination of zirconia (ZrO₂), alumina (Al₂O₃), and silica (SiO₂). These bricks are renowned for their exceptional resistance to thermal shock, corrosion, and wear. They are particularly suited for high-temperature environments where they come into contact with molten glass, metals, and aggressive slags.

Zirconia Corundum Brick Specifications

| Item | AZS-33 | AZS-36 | AZS-41 |

|---|---|---|---|

| Al2O3 Content | Bal. | Bal. | Bal. |

| ZrO2 Content | % ≥ 33 | % ≥ 33 | % ≥ 41 |

| SiO2 Content | % ≤ 16 | % ≤ 14 | % ≤ 13 |

| Fe2O3 + TiO2 | % ≤ 0.3 | % ≤ 0.3 | % ≤ 0.3 |

| Bulk Density | g/cm³ | 3.5-3.6 | 3.75 |

| Cold Crushing Strength | MPa | 350 | 350 |

| Thermal Expansion Coefficient (1000℃) | 0.80 | 0.80 | 0.80 |

| Exudation Temperature of Glass Phase | ℃ | 1400 | 1400 |

| Baddeleyite | 32 | 35 | 40 |

| Glass Phase | 21 | 18 | 17 |

| α-Corundum | 47 | 47 | 43 |

Zirconia Corundum Brick Applications

- Glass Industry: Extensively used for lining glass furnaces, particularly in areas that come into contact with molten glass.

- Steel and Metallurgy Industry: Applied in steel-making furnaces, ladles, and other components exposed to aggressive slags and molten metals.

- Non-Ferrous Metal Smelting: Used for lining furnaces in the smelting of non-ferrous metals such as copper, lead, and zinc.

- Petrochemical Industry: Utilized in reactors and other high-temperature equipment exposed to harsh chemical environments.

Silica Checker Brick Packaging

Our Zirconia Corundum Brick is meticulously handled during storage and transportation to maintain its quality and performance.

FAQs

Q1: What is Zirconia Corundum Brick?

Zirconia Corundum Brick is a high-performance refractory brick made from a mix of zirconia, alumina, and silica. It is designed for high-temperature applications where durability and resistance to thermal shock, corrosion, and wear are critical.

Q2: What are the main applications of Zirconia Corundum Brick?

These bricks are primarily used in the glass industry for lining glass furnaces, in steel and metallurgy industries for furnaces and ladles, in non-ferrous metal smelting furnaces, and in the petrochemical industry for reactors.

Q3: How does Zirconia Corundum Brick handle extreme conditions?

Zirconia Corundum Brick excels in extreme conditions due to its high resistance to thermal shock, corrosion, and wear. Its high thermal stability and mechanical strength make it suitable for applications involving molten glass, metals, and aggressive slags.

Q4: What are the key properties of Zirconia Corundum Brick?

Key properties include high bulk density, excellent cold crushing strength, low thermal expansion, and high resistance to thermal shock and chemical attack. The exudation temperature of the glass phase and Baddeleyite content are also significant indicators of performance.

Request a Quote

-

Attachment (Optional)

No file chosen