Do you have any questions? Email Us

[email protected]

Ceramic Material Comparison Chart

Explore our interactive ceramic material comparison chart below, designed to help you easily compare different materials based on their key properties, and find the best fit for your application.

READ MORE >

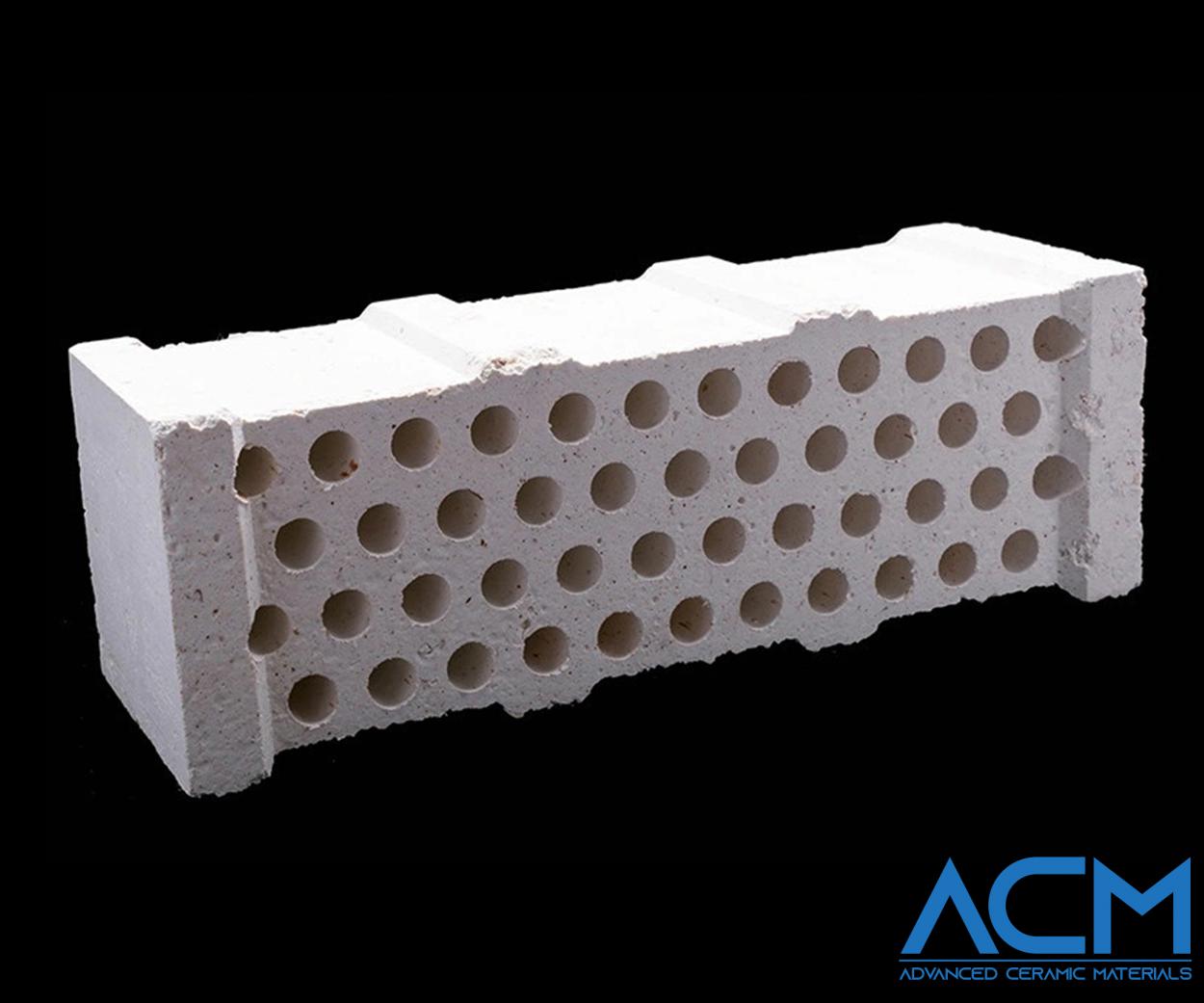

AC6129 Cordierite Refractory Brick

Cordierite Refractory Brick Overview

Cordierite Refractory Brick is a high-performance refractory material primarily composed of cordierite, a magnesium aluminum silicate mineral. Renowned for its low thermal expansion, high thermal shock resistance, and excellent insulating properties, these bricks are specifically designed for environments where high resistance to thermal cycling—rapid heating and cooling—is essential.

Cordierite Refractory Brick Specifications

|

Item |

Materials for ceramic kiln furniture |

|||||||

|

LUA |

LEN |

FON |

FAC |

ROY |

LUK |

COB |

||

|

Material |

Cordierite-Mullite |

|||||||

|

Chemical Composition |

Al2O3 % |

40 |

41 |

36 |

39 |

41 |

43 |

46 |

|

SiO2 % |

49 |

48 |

52 |

49 |

47 |

46 |

44 |

|

|

MgO % |

6.5 |

7.0 |

7.0 |

8.0 |

7.0 |

7.0 |

6.0 |

|

|

Bulk density g/cm3 |

1.95 |

1.90 |

1.85 |

1.82 |

1.95 |

1.82 |

2.00 |

|

|

Apparent porosity % |

26 |

28 |

28 |

29 |

26 |

33 |

25 |

|

|

Expansion (20℃-1000℃/10-6K-1) |

2.3 |

2.3 |

2.6 |

2.2 |

2.2 |

2.5 |

3.1 |

|

|

Max Working Temperature |

1300 |

1250 |

1300 |

1320 |

1280 |

1280 |

1350 |

|

Cordierite Refractory Brick Applications

- Kilns and Furnaces: Ideal for use in ceramic kilns and industrial furnaces due to their excellent resistance to thermal shock.

- Ovens: Perfect for pizza and baking ovens, providing consistent and even heating.

- Catalyst Support: Serves as a support material in automotive catalytic converters and industrial reactors.

- Thermal Insulation: Used in glassmaking and metal processing furnaces to enhance insulation.

- Heater Panels: Utilized in electric and infrared heaters for their high-temperature resistance.

Request a Quote

-

Attachment (Optional)

No file chosen

I would like to join the mailing list to receive updates from Advanced Ceramic Materials .

*e-mail address with your company's domain name is preferred. Otherwise, we may not be able to process your inquiry.

Tel : (949) 407-8904

Address : 1940 E Deere Ave #100 Santa Ana, CA 92705 U.S.A.

Main Products

Useful Links

Featured Posts

Search

Copyright © 1994-2025 Advanced Ceramic Materials owned by Oceania International LLC, All Rights Reserved.