Alumina Rods: A Versatile Solution for High-Temperature Applications

Introduction

Alumina, also known as aluminum oxide (Al2O3), is a widely used ceramic material known for its exceptional properties and versatility. Among its various forms, alumina rods have gained popularity in various industries for their ability to withstand high temperatures and provide excellent thermal, mechanical, and electrical properties. This article will explore the applications and benefits of alumina rods in high-temperature environments.

Read more: Why Alumina Rods are Preferred in Heat Exchanger Applications?

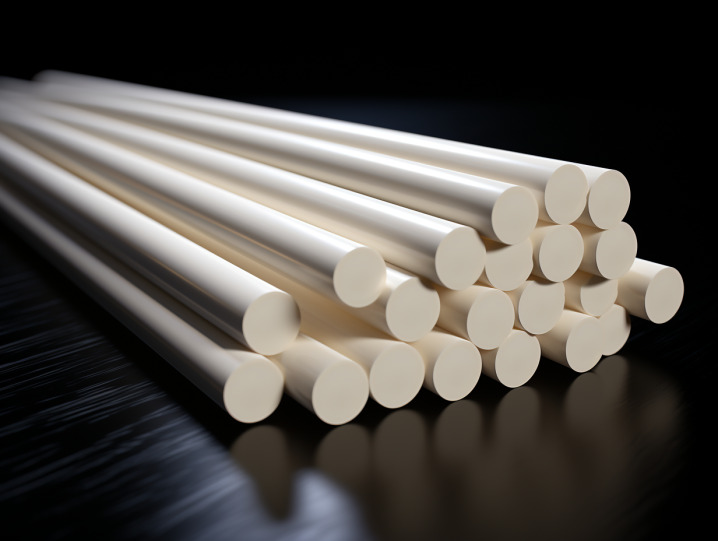

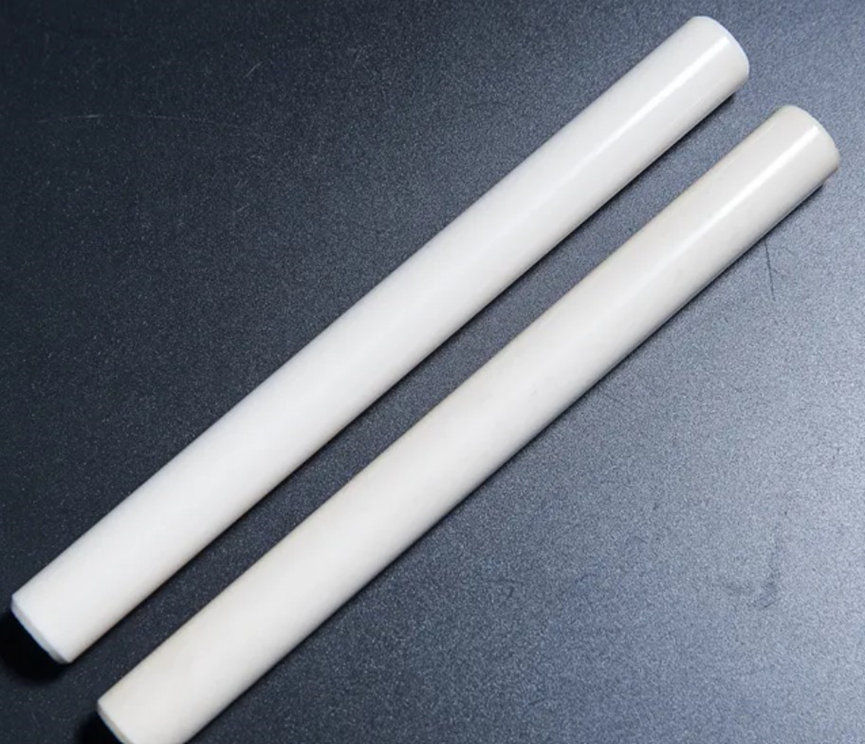

What Are Alumina Rods?

Alumina rods are made of high-purity aluminum oxide ceramics. This material is widely used in many industries due to its excellent properties like high strength, high wear resistance, and biocompatibility.

Figure 1. Alumina Rods

Alumina ceramic is highly versatile and finds applications in various industries like industrial appliances, coatings, lab wares, engineered ceramics, refractories, artificial bones, abrasives, and consumer electronics. The material is also employed for grinding hard materials and manufacturing parts for CVD, ion implants, photolithography, and semiconductor components.

Related reading: Everything You Need to Know about Alumina Ceramics

How Are Alumina Rods Used for High-Temperature Applications?

1. Thermal Insulation:

Alumina rods are especially useful for high-temperature applications due to their excellent thermal insulation properties. With a high melting point, typically around 2,050°C (3,722°F), they retain structural integrity at elevated temperatures. This makes alumina rods suitable for use as insulation components in furnaces, kilns, and high-temperature equipment. They help minimize heat transfer, reduce energy loss, and maintain a stable thermal environment, ensuring efficient and precise temperature control.

2. Electrical Insulation:

Alumina rods possess excellent electrical insulation properties, making them ideal for applications that require electrical isolation at high temperatures.

They are commonly used as insulators in electrical heating elements, resistors, and other electronic components operating in demanding thermal environments. Alumina rods provide reliable electrical insulation, preventing leakage and ensuring the safe operation of electrical systems even at elevated temperatures.

3. Mechanical Strength and Stability:

Alumina rods exhibit remarkable mechanical strength and stability, making them suitable for demanding high-temperature applications. Their high compressive strength allows them to withstand mechanical stresses and resist deformation under heavy loads. Alumina rods maintain their dimensional stability even at extreme temperatures, ensuring the integrity of structural components and preventing distortion or failure.

4. Chemical Inertness:

Alumina is chemically inert and resistant to many corrosive substances. Therefore, alumina rods are suitable for applications where chemical compatibility is crucial. They can be used as reaction vessels, crucibles, or components in chemical processing equipment that involves aggressive chemicals or reactive atmospheres. By providing a protective barrier, these rods ensure the purity of the processed materials and enhance the longevity of the equipment.

5. Wear and Abrasion Resistance:

Due to their excellent wear and abrasion resistance, alumina rods are suitable for applications where materials are subjected to friction or mechanical wear at high temperatures.

They find use in industries such as metallurgy, mining, and materials handling, where abrasive materials are encountered. Alumina rods’ superior wear resistance reduces material loss and extends the lifespan of components in high-temperature environments.

6. Research and Development:

Alumina rods play a vital role in research and development activities, particularly in high-temperature experiments and testing.

Their exceptional thermal and mechanical properties make them suitable for various laboratory applications, including sample holders, crucibles and supports in materials characterization techniques. Alumina rods provide stability, reliability, and consistency in high-temperature research environments, enabling precise measurements and reliable data acquisition.

Conclusion

In a word, alumina rods are versatile solutions for high-temperature applications. Their unique combination of thermal insulation, electrical insulation, mechanical strength, chemical inertness, wear resistance, and stability make them indispensable in industries such as manufacturing, energy, research, and materials processing. As technology advances and industries seek materials that can withstand increasingly demanding conditions, alumina rods will continue to play a crucial role in enabling high-temperature processes and applications.

Advanced Ceramic Materials (ACM) is a leading supplier of alumina ceramics. For more information, please visit our homepage.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments