SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

Abstract: In advanced plasma etch, the focus ring is a consumable component with an outsized impact on yield and cost. As aspect ratios increase and process windows narrow, the choice between traditional quartz and high-performance silicon carbide (SiC) becomes critical. This article provides a data-driven comparison of their corrosion rates, lifetime, and ultimate impact on process stability. We introduce a Total Cost of Ownership model that quantifies how SiC's superior durability can lower cost per wafer despite a higher unit price, and offer a selection guide based on etch chemistry and device architecture.

Introduction

In high-aspect-ratio etch processes for 3D NAND, advanced DRAM, and logic fin formation, plasma density must be meticulously uniform from the center to the very edge of the wafer. The focus ring (or edge ring) sits just outside the wafer, electrically and physically shaping the plasma sheath at this critical boundary. Its primary function is to ensure that features etched at the wafer's edge have the same critical dimension (CD) and profile as those in the center.

Failure is Not an Option: As the focus ring erodes from continuous plasma exposure, its geometry changes. This alters the local plasma conditions, leading to edge CD drift, profile tilting, and ultimately, yield loss. The ring must be replaced before this drift exceeds tolerance—but frequent replacements carry their own cost in parts, downtime, and process requalification. Selecting the right ring material is therefore a direct investment in process stability and factory efficiency.

Material Showdown: Quartz vs. Silicon Carbide

The two dominant materials represent a classic trade-off between initial cost and long-term performance.

| Property | Quartz (Fused Silica) | Silicon Carbide (SiC) | Implication for Etch Performance |

|---|---|---|---|

| Material Cost | Low | High (3x - 5x unit cost of quartz) | Direct impact on parts inventory budget. |

| Hardness & Wear Resistance | Moderate (Mohs ~7) | Extremely High (Mohs ~9.5) | SiC is vastly more resistant to physical sputtering and ion bombardment. |

| Etch Rate in Fluorine Plasma | High | Extremely Low | Key Differentiator. In common CF₄, SF₆, NF₃ plasmas, SiC erodes orders of magnitude slower. |

| Etch Rate in Chlorine Plasma | Moderate | Low | SiC maintains a significant advantage, though the gap may be smaller than in F-based chemistry. |

| Thermal Conductivity | Low (~1.4 W/m·K) | Very High (~120 W/m·K) | SiC rings maintain more stable temperature, reducing process drift during long runs. |

Corrosion Rate Data & Lifetime Example:

In a high-power, fluorine-based 3D NAND staircase etch process:

-

A quartz focus ring may have an erosion rate of ~0.5 µm/hour. With an allowable wear budget of 2-3 mm, its lifespan is ~4,000 to 6,000 wafer starts.

-

A silicon carbide focus ring in the same process may erode at < 0.05 µm/hour. This extends its potential lifespan to > 40,000 wafer starts—a 6x to 10x improvement.

This disparity means that while a quartz ring might be changed every 2-3 weeks in a high-utilization tool, an SiC ring could last 6 months or more, fundamentally changing the maintenance rhythm.

The True Cost: A Total Cost of Ownership Analysis

Evaluating focus rings on unit price alone is a costly mistake. The Total Cost of Ownership framework reveals the true economics.

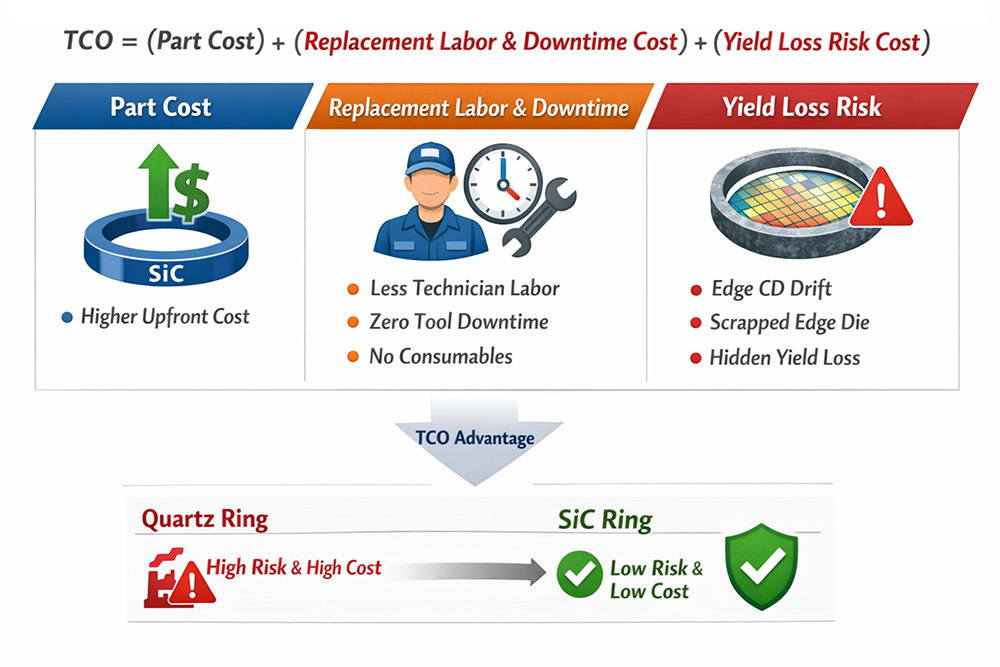

TCO = (Part Cost per Ring) + (Replacement Labor & Downtime Cost) + (Yield Loss Risk Cost)

-

Part Cost: SiC has a higher upfront cost.

-

Replacement Cost: This is where SiC dominates. Fewer changeouts mean:

-

Less technician labor.

-

Zero tool downtime for ring changes (scheduled during other preventive maintenance).

-

No consumables (gaskets, bolts) or process gases used for chamber re-stabilization after each change.

-

-

Yield Loss Risk: A worn quartz ring causes gradual edge CD drift, potentially scrapping edge die for thousands of wafers before it's caught. SiC's stability virtually eliminates this hidden yield tax.

Illustrative TCO Comparison (Per 100,000 Wafers):

| Cost Component | Quartz Focus Ring | Silicon Carbide Focus Ring |

|---|---|---|

| Number of Rings Used | 20 | 2 |

| Total Parts Cost | $X | ~1.5X - 2X |

| Replacement Downtime Cost | High (19 extra events) | Low |

| Estimated Yield Impact Cost | Significant (edge drift) | Negligible |

| Total Cost of Ownership | X + High + Significant | ~(1.5-2X) + Low + Negligible |

Conclusion: In nearly all high-volume, advanced etch applications, the TCO for SiC is lower than for quartz within 12-18 months, despite the higher unit price.

Selection Guide: Matching Material to Application

The optimal choice depends on your specific process:

Choose Quartz When:

-

Process: Less aggressive etch steps (e.g., some oxide etch, older technology nodes).

-

Chemistry: Processes where the etch selectivity to quartz is favorable.

-

Driver: Extreme upfront cost sensitivity on a low-utilization or R&D tool, where process stability over long runs is less critical.

Choose Silicon Carbide (SiC) When:

-

Process: Advanced high-aspect-ratio etch (3D NAND, FinFET, GAA), high-power processes.

-

Chemistry: Fluorine-based plasmas (CF4, SF6, NF3) where quartz erodes rapidly.

-

Driver: Maximizing tool uptime, process stability, and overall yield. When managing a fleet of tools, reducing the variability and frequency of consumable changes is a key operational goal.

Conclusion: Investing in Process Stability

As etch processes push deeper and narrower, the margin for error vanishes. The focus ring transitions from a simple consumable to a critical process-stabilizing component. Selecting silicon carbide is an engineering decision that pays for itself not on the procurement invoice, but on the fab floor—through uninterrupted production runs, predictable maintenance schedules, and the protection of yield at the wafer's vulnerable edge.

The shift from quartz to SiC is not merely a material substitution; it is an operational upgrade that aligns consumable strategy with the demands of leading-edge manufacturing.

Ready to model the TCO and yield impact for your specific etch process?

Contact our process engineering team to receive etch rate data for your chemistry and access an interactive TCO model to compare quartz and SiC for your production environment.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments

- Aluminum Oxide Ceramics: Properties and Applications