Applications of ZSBN Ceramics: Molds and Nozzles for Molten Metal Handling

ZSBN (Zirconium Silicon Boron Nitride) is gaining recognition for its specialized applications in molten metal handling. Their ability to maintain stability under extreme conditions makes them ideal for molds and nozzles used in high-temperature environments. This article explains how ZSBN ceramics improve performance and durability in industrial processes.

ZSBN Ceramics in Molds for Molten Metal

ZSBN ceramics are a top choice for making molds that handle molten metals. These molds need to stay strong and keep their shape at very high temperatures. ZSBN ceramics are perfect for this because they have excellent thermal stability, making them great for precise casting.

-

Precision in Metal Casting: ZSBN ceramic molds help create accurate metal parts. They don’t change shape when they get hot, which means the molds keep their form. This makes sure that the metal parts come out just right, even with complex shapes.

-

Smooth Surface Finish: ZSBN ceramic molds give metal parts a smooth surface. This means less time spent on extra polishing or machining later. It saves both time and money in the manufacturing process.

-

Durable and Reusable: ZSBN molds are tough and can be used many times without wearing out. Their durability makes them a cost-effective choice for big production jobs where you need to keep quality high.

ZSBN Nozzles for Molten Metal

ZSBN nozzles play a key role in controlling the flow of molten metal in various industries. They are designed to work well in high-temperature environments where stability and precision are critical.

-

Precise Flow Control: ZSBN nozzles help manage the flow of molten metal with great accuracy. This precise control is important in processes like metal casting and injection molding. It ensures that the metal flows smoothly, reducing the chances of defects and improving the quality of the final products.

-

Clogging Resistance: Unlike many traditional materials, ZSBN nozzles resist clogging even under continuous, high-temperature conditions. Their smooth internal surface allows molten metal to pass through easily without getting blocked. This feature helps keep the production line running without frequent interruptions or downtime.

-

Extended Service Life: ZSBN nozzles are highly durable and have a much longer lifespan compared to other materials. They can handle repeated cycles of heating and cooling without cracking or wearing out. This durability makes them a reliable choice for demanding environments, reducing the need for frequent replacements and maintenance.

Benefits of ZSBN in Molten Metal Applications

Focusing on ZSBN ceramics for molds and nozzles brings several notable benefits to the table, directly impacting production quality and cost-efficiency:

-

Reduced Metal Contamination: ZSBN ceramics prevent unwanted reactions between the molten metal and the mold or nozzle. This reduction in contamination is critical for maintaining the purity and integrity of the final products.

-

Long-Term Cost Savings: Although the initial investment in ZSBN ceramics may be higher, their long-term durability and reduced need for replacements lower overall maintenance costs. This longevity translates to more efficient production cycles and less downtime.

-

Improved Product Precision: The ability of ZSBN molds and nozzles to maintain exact specifications under high temperatures ensures that the produced metal parts meet strict quality standards, which is essential in industries like aerospace and automotive.

Key Industries Utilizing ZSBN Molds and Nozzles

ZSBN has become crucial in various industries that require durable and high-performance materials for molten metal handling. The following sectors benefit significantly from the use of ZSBN ceramic molds and nozzles:

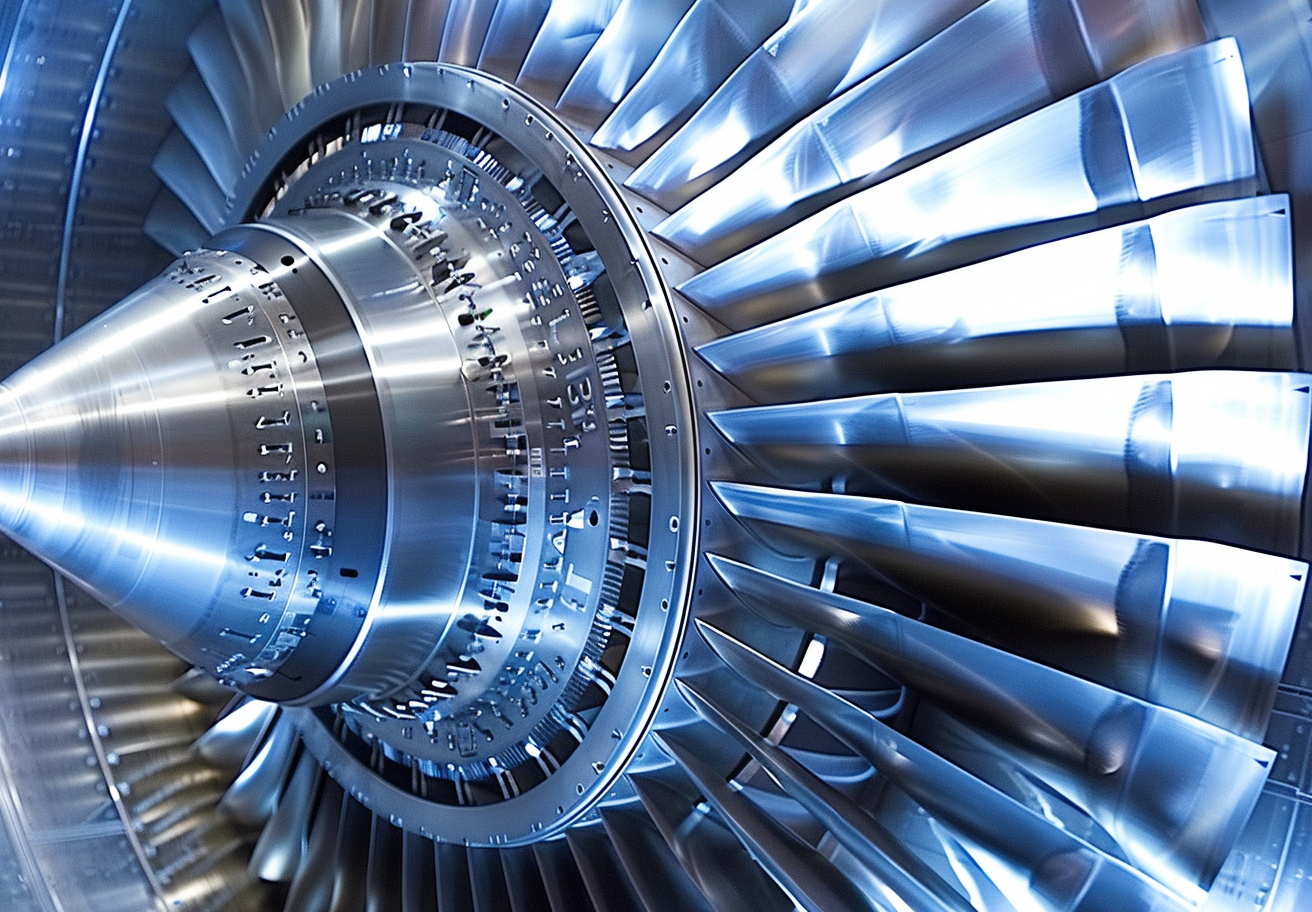

- Aerospace: The aerospace industry needs parts that are precise and reliable. ZSBN ceramic molds help make parts for jet engines and turbines. They keep their shape even in extreme heat, making sure each part meets safety standards.

- Automotive Manufacturing: ZSBN ceramics are used to make engine parts, brakes, and transmission systems. These parts must handle high stress and heat. ZSBN molds and nozzles help produce strong, consistent components that improve vehicle performance.

- Metal Foundries and Casting: Foundries use ZSBN ceramics to create metal parts. These ceramics handle molten metal at high temperatures without breaking down. This makes them perfect for casting precise parts in aluminum and other metals.

- Electronics and Semiconductors: ZSBN ceramics are also used in electronics. They create molds for parts that need a clean, non-reactive environment. ZSBN’s low expansion and chemical resistance ensure the parts are made with great accuracy.

- Energy and Power Generation: ZSBN ceramics are used in power plants and gas turbines. They can handle high heat and resist damage, which helps these systems run more efficiently and last longer.

- Chemical Processing: In chemical plants, ZSBN ceramics are important for dealing with harsh chemicals and high heat. They keep molds and nozzles strong and stable, making sure the equipment works safely and effectively.

Conclusion

ZSBN ceramics are changing how industries handle molten metals, especially in molds and nozzles. They stand up to extreme heat, resist chemicals, and keep their shape, making them a top choice for these uses. This leads to better efficiency, higher product quality, and cost savings.

Advanced Ceramic Materials (ACM) provides reliable ZSBN ceramic solutions to help companies improve performance and extend the life of their equipment.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- Boron Nitride in Cosmetics: Enhancing Performance and Sensory Appeal

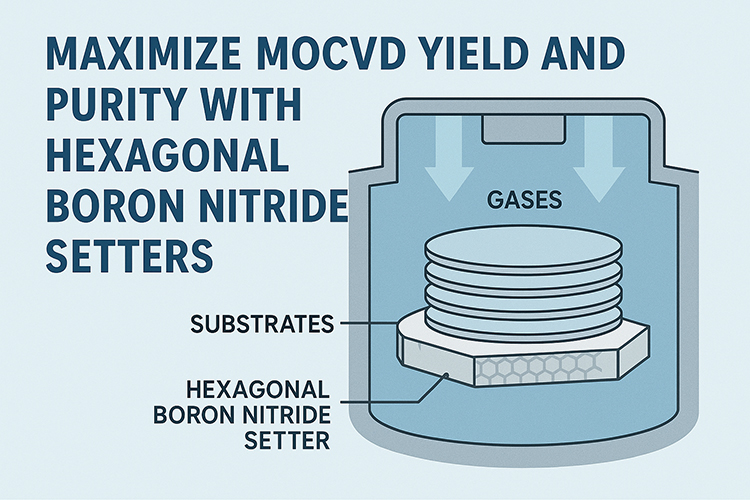

- Maximize MOCVD Yield and Purity with Hexagonal Boron Nitride Setters

- What Are the Advantages and Uses of Boron Nitride Ceramic Sheet?

- The Compression Annealing Advantage for Pyrolytic Boron Nitride

- Beyond Insulation: The Surprising Spectrum of Ceramic Thermal Conductivity