Importance of Ceramic Brake Pads

Why Brake Pads Matter

Brake pads are one of the components of disk brakes. They are mostly used in the automotive industry. In disc brakes, each disc rotor has two brake pads. Brake pads use friction to convert mechanical energy to heat energy. When the brakes are applied, the two brake pads clamp together on the spinning rotor, causing the vehicle to slow down and stop. Brake pads came into the limelight after the second world war. They came to replace the drum brakes. By the 1960s, most cars were manufactured with brake pads as opposed to drum brakes. Brake pads are susceptible to wear. If they are not maintained properly, it can result in automobile accidents or malfunctions. Thus it is advisable to inspect your brake pads every 5000 miles. It is also recommended that you change your brake pads every 50000 miles. Despite all these guidelines, different vehicles have different requirements for maintaining their brake pads.

Properties of Good Ceramic Brake Pads

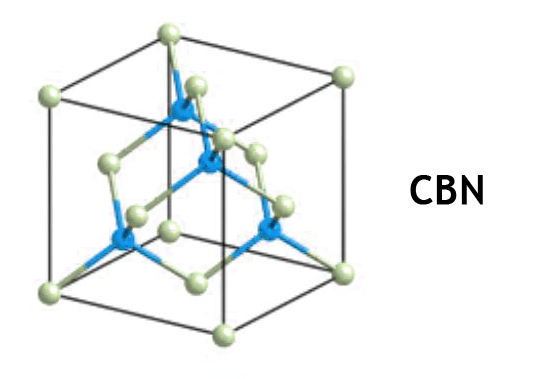

So far, we have discussed how important it is to have brake pads in a vehicle. But how do you know that the brake pads you have in your vehicle are good and capable of performing all the functions of brake pads efficiently A large part of ceramic brakes is made of high-quality advanced ceramic-silicon carbide. The excellent properties of SiC ceramics endow the brake pad with special properties, making it more rigid and durable. Other ceramics, such as alumina and boron carbide, are also used to manufacture brake pads. Here are some of the properties of good ceramic brake pads.

Brake Fade Resistance

Good ceramic brake pads generally can resist brake fade. Brake fade is typically caused by overheating in brake pads as a result of converting kinetic energy to heat energy when the brake is applied. Brake fade decreases the efficiency of ceramic brake pads considerably.

Corrosion and Oxidation Resistance

A good ceramic brake pad should be resistant to corrosion and oxidation. It should be able to withstand exposure to chemicals without any change in mechanical properties. Corrosion and oxidation can greatly decrease the half-life of a brake.

Low Friction Coefficient

A low friction coefficient is one property to look out for when choosing a ceramic brake pad. The friction coefficient should be low enough that the wheels do not lock. However, it should not be so low that there is insufficient stopping power. The friction coefficient of an ideal ceramic brake pad lies between 0.3 and 0.5.

Typical Advantages of Ceramic Brake Pads

Ceramic brake pads are a new technology. However, they are now used for popular vehicle brands like Mercedes Benz, Jaguar, Lexus, Range Rover, and so on. What is it about ceramic brake pads that make them stand out amongst other types of brake pads.

Durability

Ceramic brake pads have a track record of lasting longer than other types of brake pads.

Less Brake Dust

Ceramic brake pads are more wear resistant than other types of brake pads. Hence, they produce less brake dust. While other brake pads may produce enough dust to affect other components of disc rotors, ceramic brake pads do not.

Quiet Braking

Unlike other types of brake pads like fully metallic brake pads, ceramic brake pads do not make loud sounds. This is because the noise they produce exceeds the normal hearing range in humans.

Stability

Ceramic brake pads usually exhibit more stability over a wide range of temperatures than other types of brake pads.

Other Types of Brake Pads

Organic Brake Pads

Organic Brake pads are the softest types of brake pads. Due to their characteristic softness, they wear easily. Furthermore, they are likely to produce huge amounts of brake dust due to how easily they wear. The brake dust goes ahead to affect other components of the brake disc. Organic brake pads are generally composed of glass, rubber, and resin. It is important to replace the brake pads frequently in vehicles that use organic brake pads.

Semi-metallic Brake Pads

Semi-metallic brake pads are made from both synthetics and metals. They are usually more heat and wear-resistant than organic brake pads. Semi-metallic brake pads are not the most ideal brake pads for heavy braking applications. However, adding more metals to them makes them last longer.

Fully Metallic Brake Pads

This type of brake pad is hardly used for day-to-day braking applications. They are most often used in racing vehicles and have a long lifespan. Fully metallic brake pads are made wholly from sintered steel. These brake pads can be extremely loud and they tend to wear off the disc rotors. In addition, more force must be applied to them for a vehicle to slow down.

Conclusion

Although ceramic brake pads are a new technology, they have proven to be highly reliable and efficient. More research is still ongoing to learn more about how the benefits of ceramic brake pads can be maximized. For more information about high-quality advanced ceramic materials, please visit https://www.preciseceramic.com/.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}