An Overview of Nozzle Materials: Including ZSBN and Other Advanced Options

Introduction

Nozzle materials are essential components in various industrial applications, ranging from manufacturing and aerospace to electronics and chemical processing. These materials must meet stringent requirements to perform reliably under extreme conditions. This article explores the key characteristics of nozzle materials and highlights advanced options, including ceramic and composite materials, suitable for demanding environments.

Additionally, we will discuss the unique applications and performance factors that make these materials indispensable in modern industries.

Key Performance Requirements for Nozzle Materials

Nozzle materials must possess several critical properties to ensure their effectiveness and durability:

-

Thermal Stability: The ability to withstand high temperatures without degradation, making them ideal for processes involving molten materials or high-energy outputs.

-

Wear Resistance: Resistance to abrasion and mechanical wear for extended use, especially in environments where particulate matter or high pressures are present.

-

Chemical Inertness: Protection against corrosive chemicals and molten substances, ensuring a longer operational lifespan in harsh conditions.

-

High Strength-to-Weight Ratio: Ensures structural integrity while minimizing bulk, which is crucial for applications where precision and efficiency are priorities.

Typical Nozzle Materials and Their Characteristics

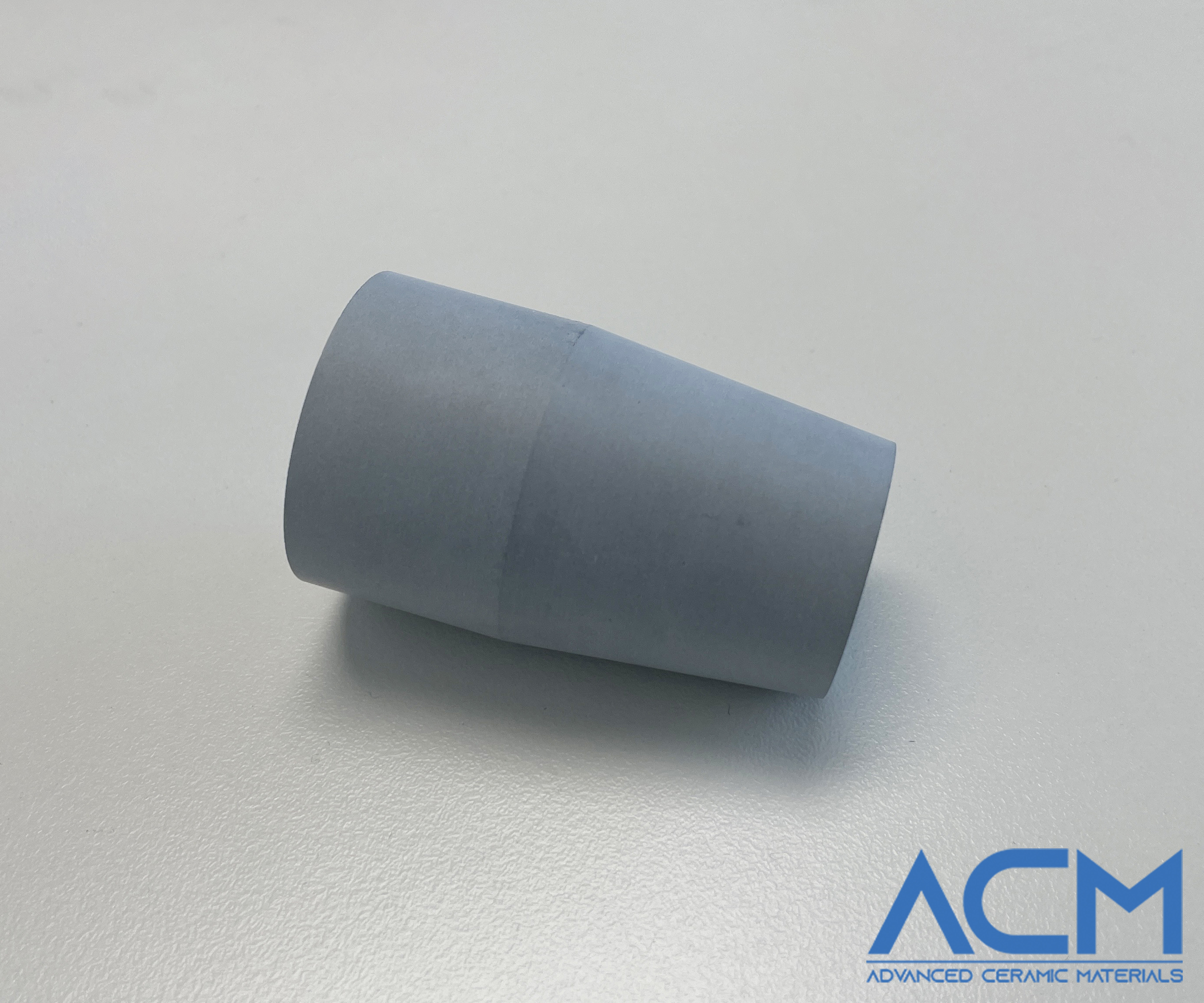

1. Zirconia-Based Composites (e.g., ZSBN)

Zirconia-based composites, such as ZSBN (Zirconia Silicon Boron Nitride), offer a unique combination of properties:

-

Composition: Combines zirconia for mechanical strength, silicon for structural stability, and boron nitride for thermal shock resistance and lubricity.

-

Key Advantages:

-

High thermal stability, making them ideal for high-temperature environments.

-

Low thermal expansion, reducing the risk of cracking during rapid temperature changes.

-

Excellent chemical resistance, suitable for handling corrosive and reactive substances.

-

Self-lubricating properties, reducing friction in precision applications.

-

-

Applications: Commonly used in aerospace propulsion systems, semiconductor manufacturing, and molten metal handling, ZSBN is particularly valued for its performance in extreme environments.

2. Silicon Carbide (SiC)

Silicon carbide nozzle is renowned for its hardness and thermal conductivity:

-

Properties: Exceptional wear resistance and capability to endure high temperatures without significant performance loss.

-

Applications: Ideal for abrasive environments and high-temperature industrial processes, such as kiln components and chemical reactors.

3. Alumina (Al₂O₃)

Alumina offers a balance of performance and cost-effectiveness:

-

Properties: Good thermal stability and chemical resistance, along with a relatively lower cost compared to advanced composites.

-

Applications: Suitable for general-purpose industrial applications, including wear-resistant linings and standard nozzle components.

4. Tungsten Carbide (WC)

Tungsten carbide provides unmatched wear resistance and toughness:

-

Properties: Extremely hard and resistant to deformation, even under intense mechanical stress.

-

Applications: Often used in high-pressure and abrasive conditions, such as mining equipment and high-impact machinery.

5. Molybdenum Disilicide (MoSi₂)

Molybdenum disilicide is valued for its oxidation resistance:

-

Properties: Performs exceptionally well at high temperatures, maintaining structural integrity in oxidative environments.

-

Applications: Frequently used in high-temperature furnaces, heating elements, and chemical processing.

6. Advanced Polymer Composites

Lightweight and chemically inert, polymer composites are ideal for specialized conditions:

-

Properties: High resistance to corrosion and lower weight compared to metals and ceramics, making them versatile in specific environments.

-

Applications: Preferred in low-temperature or highly corrosive environments, such as in food processing and medical devices.

Applications Across Industries

The choice of nozzle materials depends on the operational environment and specific industrial requirements. Examples include:

-

Aerospace: High-temperature propulsion systems and precision nozzles designed to withstand intense thermal and mechanical stress during flight operations.

-

Manufacturing: Nozzles for metal casting, 3D printing, and other high-performance processes where precision and durability are key.

-

Electronics: Precision nozzles used in semiconductor manufacturing ensure accurate material deposition during production.

-

Chemical Processing: Corrosion-resistant nozzles for handling reactive chemicals in harsh environments, contributing to safety and efficiency.

Conclusion

Selecting the right nozzle material is critical for ensuring performance and durability in demanding industrial applications. Materials such as ZSBN, silicon carbide, and tungsten carbide offer unique advantages tailored to specific needs. Advanced Ceramic Materials (ACM) is a trusted supplier of high-quality ceramic nozzles and other advanced ceramic materials, meeting the diverse demands of industries worldwide. With an extensive portfolio and expert support, ACM ensures that customers receive materials optimized for their applications. For more information or assistance in selecting the right material, contact ACM today.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- Boron Nitride in Cosmetics: Enhancing Performance and Sensory Appeal

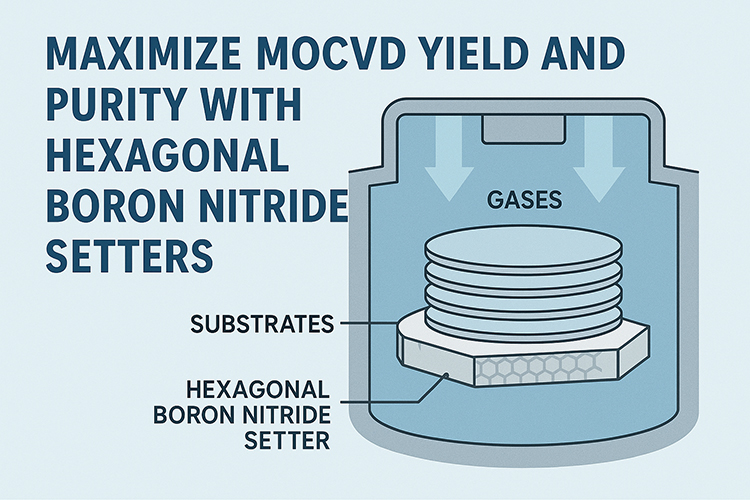

- Maximize MOCVD Yield and Purity with Hexagonal Boron Nitride Setters

- What Are the Advantages and Uses of Boron Nitride Ceramic Sheet?

- The Compression Annealing Advantage for Pyrolytic Boron Nitride

- Beyond Insulation: The Surprising Spectrum of Ceramic Thermal Conductivity