SiC Foam Ceramics: Properties and Applications

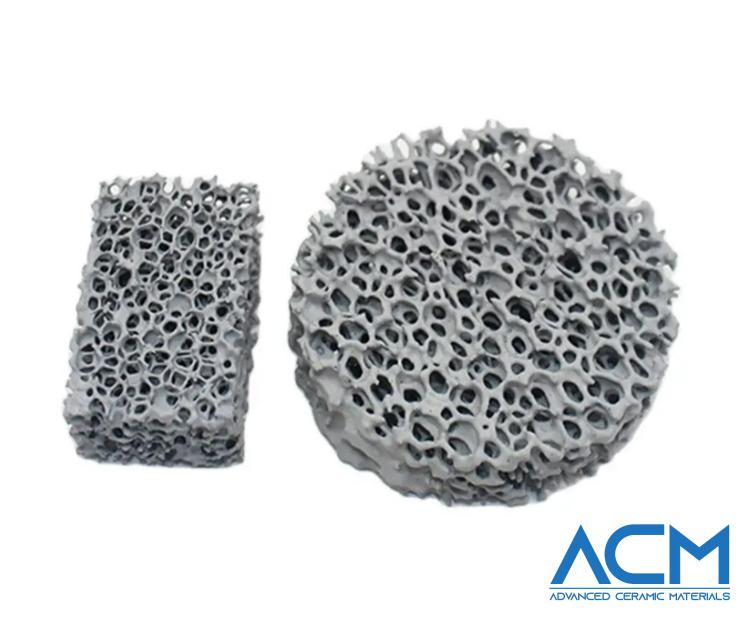

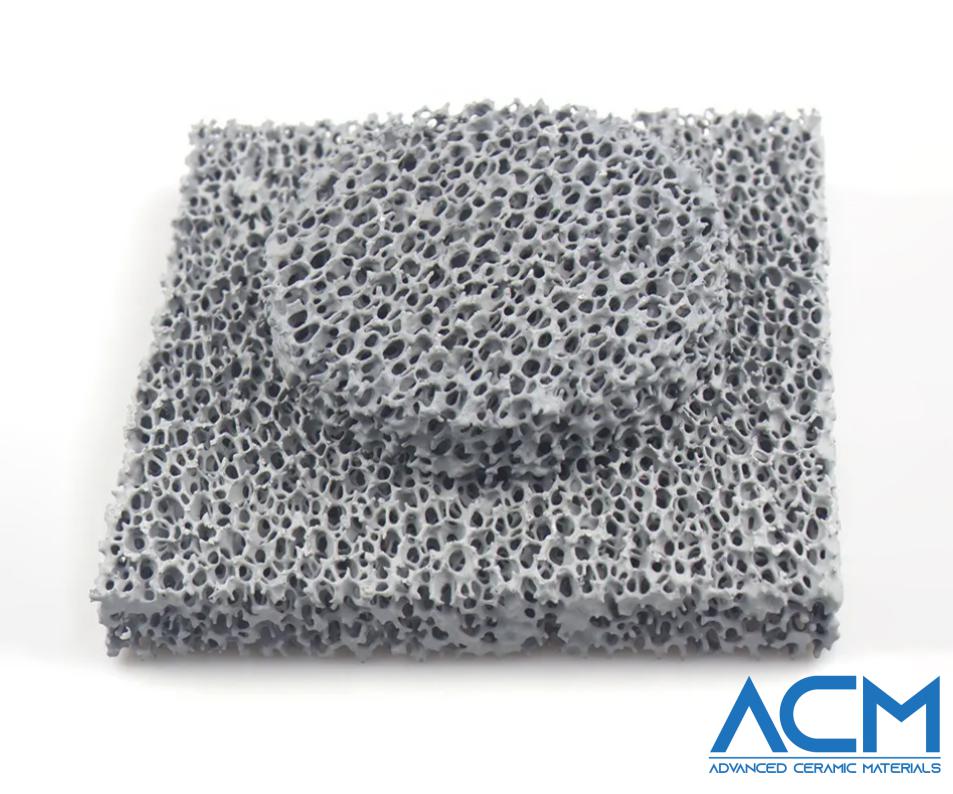

Silicon carbide foam ceramics represent an interesting group of porous ceramics. They possess good mechanical properties in addition to uniform thermal and electrical response. SiC foam ceramics are created by filling a polymer foam with a precursor of the ceramic material and heat-treating it. During this process, the polymer is oxidized while avoiding damage to a silicon carbide network. Because of these unique characteristics, SiC foams find application in numerous practical fields by different researchers and engineers.

Key Properties

Mechanical Properties

Silicon carbide foams are strong and stiff relative to weight. They are light weight, but not brittle or easily breakable. This is an advantage when a rigid, durable material is needed without adding weight. The material's structure can bend a little due to the porous structure, which can be advantageous in parts that must absorb vibrations or shock.

Thermal Properties

The substance is a good conductor of heat and withstands instantaneous temperature change without destruction. It is effective in high-temperature use like that in furnaces and kilns. For example, in industrial machinery for heat treatment, the ceramic insulation can handle heat transport. Its resistivity to thermal shock ensures that the material is stable despite temperature changes.

Electrical Properties

As a semiconductor, silicon carbide possesses important electrical properties. The foam texture conducts electricity under certain conditions. Modification of the process of production changes the manner in which the material conducts electricity. In life, the property proves useful in sensors and devices that need variable conductivity.

Chemical Properties

Silicon carbide is also strongly resistant to the overwhelming majority of chemicals, especially with respect to heat. The resistance of SiC foam ceramics makes them resistant to corrosion and weathering. For instance, within chemical reactors or atmospheres containing aggressive gases or liquids, SiC foam holds steady. Due to their oxidation and corrosion-resistant qualities, they are the realistic choice in extreme environments.

Major Applications

Filtration

SiC foam ceramics act as filters for molten metals, alloys, and other high-temperature fluids. Their robust structure chills out impurities. In metal treatment plants or foundries, the ceramics are a barrier containing undesired inclusions. They are also effective in filtering hot liquids or gases. The superior heat and corrosion resistance guarantee that the ceramic is not damaged under repeated use.

Thermal Insulation

These ceramics are excellent thermal insulators for use at high temperatures. Consider a stone furnace or an industrial kiln: the SiC foam ceramic holds onto the heat without permitting energy loss. This insulation with conduction of heat makes them applicable when efficiency in heating and safety are equally involved.

Acoustic Insulation

Since they possess an open-cell structure, SiC foam ceramics are excellent sound-absorbers. This characteristic is particularly useful for sound reduction. In vehicle development or building construction, these ceramics reduce or deaden noise. They provide a clean and stable option for acoustic management, rendering spaces livable or workable.

Catalyst Support

SiC foam can be employed efficiently as a catalyst carrier for chemical reactions. They possess a large surface area with many contact points. In the context of chemical processing facilities, the use of ceramic as a support can enhance the rate of reaction. Due to the rigid nature of the material, even if the reaction is heated, the catalyst will be firmly held.

Bone Implants

The biocompatibility of silicon carbide puts it in the running for application in medical implants, particularly for bones. It has a porous structure that supports bone cells to attach and grow. These ceramics, therefore, support bone regrowth and provide the structural support necessary. This feature is being researched in medical laboratories and could pave the way for longer-lasting implants in the future.

![]()

Energy Storage

Research has shown that ceramics made from SiC foam are promising in the application of energy storing devices such as supercapacitors and batteries (Liu et al. 2022). They are heat-stable and have a high surface area, hence, enhancing the effectiveness of the devices. Practically, the higher energy density positions them as a suitable candidate to be used in both mobile and stationary energy storage systems.

Water Desalination

Water purification is also an area where SiC foam ceramics have applications. They are not prone to corrosion and are very strong, thus optimal for being used in desalination membranes. Practically, the membranes filter out the salts from water, which makes the end product better in quality. The process can be done so many times because the material is not easy to damage.

Aerospace

In aerospace applications, light but robust materials are critical. SiC foam ceramics are now being used for thermal insulation of aircraft and spacecraft. They remain resistant to high temperatures without contributing significantly to weight, making them handy. This is a useful trait in aerospace applications since every gram matters.

Conclusion

SiC foam ceramics offer a blend of robust properties that suit many high-performance uses. Whether it is filtering molten metals, insulating massive furnaces, reducing noise in cars, or supporting catalysts in reactors, the ceramic meets the challenge. They have also shown promise in areas such as bone implants, energy storage, water desalination, and aerospace thermal management. Their low weight, stable performance, and flexible design add extra points in their favor.

Engineers and scientists continue to put these ceramics to work in various fields. As improvements in the manufacturing process bring about even better versions, these materials are set to bring more practical gains in industries ranging from energy to healthcare. For reliable materials sourced from experts, Advanced Ceramic Materials (ACM) is a trusted supplier for SiC foam ceramics.

Reference:

Luo, Qingyang & Liu, Xianglei & Yao, Haichen & Wang, Haolei & Xu, Qiao & Tian, Yang & Wang, Jianguo & Jin, yi & Xuan, Yimin & Ding, Yulong. (2022). Fast and stable solar/thermal energy storage via gradient SiC foam-based phase change composite. International Journal of Heat and Mass Transfer. 194. 123012. 10.1016/j.ijheatmasstransfer.2022.123012.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- Boron Nitride in Cosmetics: Enhancing Performance and Sensory Appeal

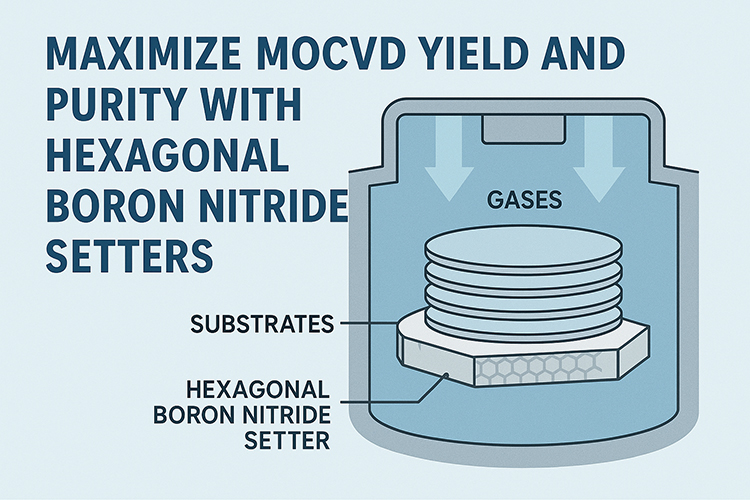

- Maximize MOCVD Yield and Purity with Hexagonal Boron Nitride Setters

- What Are the Advantages and Uses of Boron Nitride Ceramic Sheet?

- The Compression Annealing Advantage for Pyrolytic Boron Nitride

- Beyond Insulation: The Surprising Spectrum of Ceramic Thermal Conductivity