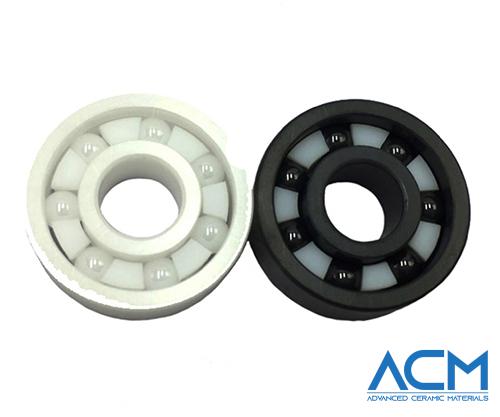

Silicon Carbide Bearing VS. Other Ceramic Bearings

Introduction

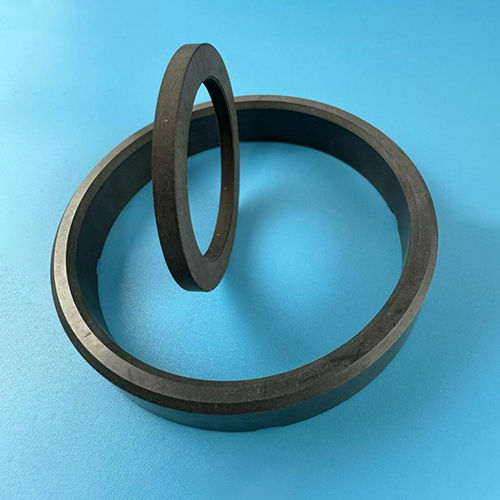

Silicon carbide bearing technology gives a hard solution when conventional steel bearings are no longer able to hold up to the test. With a history of use in extreme conditions, silicon carbide bearings have become the solid and reliable option. This article provides experienced professionals with a clear overview of why silicon carbide bearings stand out, especially where other ceramic options fall short.

Why Silicon Carbide Bearings Excel

SiC bearings have several key benefits. Over the years, I have seen many products claim superior performance. However, practical experience proves that silicon carbide stands apart for its unique properties. Let us look at the most notable features.

Exceptional Resistance to Corrosion

One of the best properties of silicon carbide is that it is resistant to harsh chemicals. Industrial bearings are exposed to acids, bases, and even saltwater in a lot of applications. Silicon carbide will be corrosion-resistant much better than most steel or hybrid bearings. For instance, on marine hardware or chemical plant, this product shows less wear and tear. When handling corrosive materials, this bearing operates without the rusting or pitting which can be seen in other types.

High-Temperature Endurance

Another essential feature is resistance to extreme heat. Silicon carbide bearings have shown consistent performance under high temperatures. They can work smoothly at temperatures of up to 1600°C without requiring any other metal parts. Consider high-temperature furnaces or metallurgical machines where other ceramic bearings might malfunction. Silicon carbide comes in here as a safe and stable solution for precision operations even in harsh thermal conditions.

Light Weight and Accurate Under Varied Conditions

Silicon carbide weighs only about 40% of steel. Its reduced weight reduces rotational inertia but enhances energy efficiency. Its low weight reduces rotational inertia, while minimal thermal expansion ensures precise operation in applications where accuracy is critical. Silicon carbide does not warp and deform in the face of temperature changes, ensuring stable functioning in applications where accuracy is the core requirement.

Electrical Conductivity Flexibility

Based on its specific composition, a silicon carbide bearing can either be made conductive or insulating. Depending on the composition, silicon carbide bearings can be conductive or insulating, giving engineers flexibility to meet specific electrical requirements in their equipment. In grounding or ensuring proper insulation, such bearings offer alternatives that are compatible with diverse industrial demands.

Caveats and Practical Considerations

No material is without its limitations. Although silicon carbide is robust under constant loads, it will become brittle if subjected to severe shocks. In locations where bearings may be exposed to unexpected shocks, safety measures must be taken. Furthermore, production of bearings of this sort is very complex. Raw materials employed are expensive, and the supply may not always match the maximum demand. Selecting silicon carbide bearings requires careful planning and precise engineering to fully leverage their capabilities.

Comparison with Other Ceramic Bearings

| Material | Key Advantage | Limitation |

|---|---|---|

| Zirconia (ZrO2) | Good resistance in moderate temperatures | Limited high-temp capacity, lower speeds |

| Silicon Nitride (Si3N4) | Light and suitable at high speeds | Vulnerable to mechanical shock, less resistant to corrosion than SiC |

| Hybrid Bearings | Combinations of steel rings and ceramic balls for speed and impact durability | Corrosion and temperature performance are limited by steel rings |

| Silicon Carbide (SiC) | Good corrosion & high-temperature ability, low weight | Brittle, costly, scarce supply, shock-sensitive |

Real-World Applications

The majority of industries rely on the unique properties of silicon carbide bearings. In chemical processing plants, the bearings bear a torrent of aggressive chemicals without showing wear and tear prematurely. They resist saltwater corrosion nicely in marine environments, allowing for smoother operations onboard different vessels.

Think about high-temperature processing equipment. Silicon carbide bearings provide accuracy for furnaces and kilns. Even in the semiconductor environment, where reliability is no less significant than accuracy, such bearings cause vital equipment to operate consistently. Small machine alignment differences can create large variations, and silicon carbide's low thermal expansion is a valuable benefit in such applications.

Choosing the Right Bearing for Your Application

Choosing the appropriate bearing material is ultimately a question of discovering its properties and comparing them with your requirements. If you're working in an extremely hostile chemical or high-temperature environment, then silicon carbide bearings are often the intelligent choice. But if your system undergoes severe shock loading or high-impact loading, you might consider using other ceramics like silicon nitride or, for that matter, a hybrid option.

Through years of experience, I’ve learned that assessing precise operating requirements is essential before choosing any bearing material. Precise evaluation of each material's benefits and drawbacks by all those within the engineering sector ensures both performance and the life of your equipment.

Conclusion

Silicon carbide bearings shine where numerous materials are pushed to their limit. Their resistance to corrosion, high-temperature operation, and consistent function under fluctuating loads set them apart in a very competitive market for ceramic products. It is clear that when conventional materials and other ceramics do not measure up to the high level of a project, silicon carbide offers a well-proven solution. While these bearings are not the cheapest, their performance in harsh conditions makes them a valuable investment.

For high-quality materials that have stood the test of time and rigorous practical use, Advanced Ceramic Materials (ACM) supplies reliable silicon carbide bearings designed to meet the challenges of today’s industrial demands.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments