SC2325 Silicon Carbide Foam Filters

- Catalog No. SC2325

- Compositions SiC ≥62.00%

- Working Temperature ≤1200°C

- Pores Per Inch 10-60

- Porosity 80–90%

- Density 0.3–0.5 g/cm³

Datasheet

Inquiry

SC2325 Silicon Carbide Foam Filters

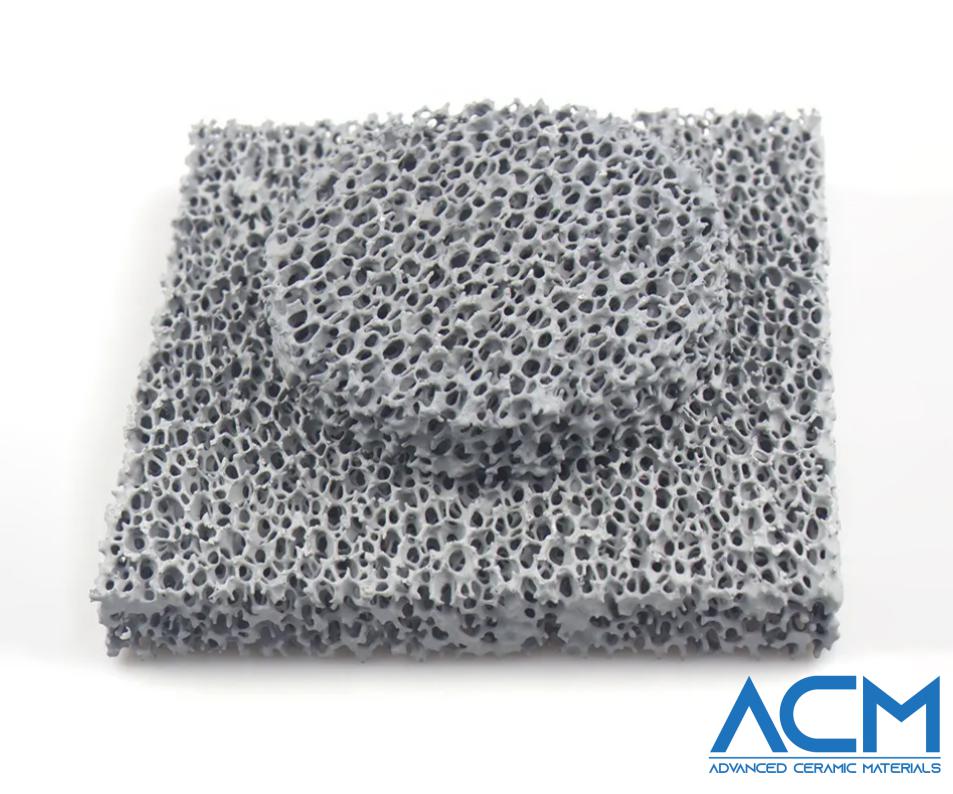

Silicon Carbide Foam Filters Description

Silicon Carbide Foam Filters are advanced porous materials primarily used for filtering cast iron and non-ferrous alloys. Made from high-purity silicon carbide, these filters feature excellent resistance to molten metal attack and corrosion. They effectively:

- Remove inclusions from molten metal.

- Reduce trapped gas to provide laminar flow.

- Improve the cleanliness of liquid metal, resulting in higher-quality castings and reduced scrap rates.

Silicon Carbide Foam Filters Specifications

| Working Temperature | ≤1540°C |

| Porosity | 80~90% |

| Compression Strength | ≥1.0Mpa (Room Temperature) |

| Volume Density | 0.3-0.5 g/cm3 |

| Thermal Shock Resistance | 1200°C ↔ Room Temperature (3 cycles) |

Chemical Composition

|

Al2O3 |

SiC |

SiO2 |

Fe2O3 |

|

≤28.00% |

≥62.00% |

≤10.00% |

≤0.50% |

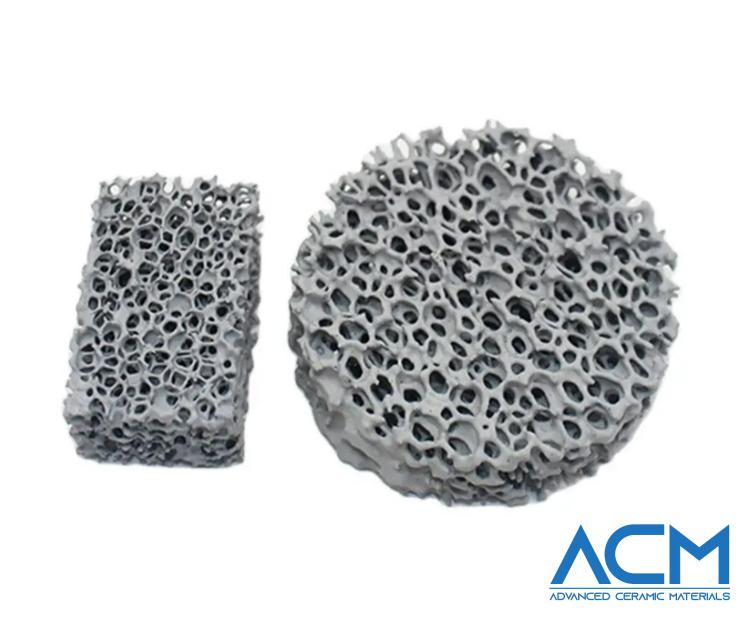

Custom sizes, thicknesses, and configurations are available upon request.

Key Features of Silicon Carbide Foam Filters

- High Filtration Efficiency: Effectively removes impurities and improves metal cleanliness.

- Thermal and Chemical Resistance: Withstands high temperatures and molten metal corrosion.

- Lightweight and Durable: Porous structure ensures excellent strength with low density.

- Customizable: Pore sizes (PPI) and dimensions can be tailored to specific requirements.

- Versatile Applications: Compatible with various molten metals, including cast iron, copper, and bronze.

Applications

Silicon Carbide Foam Filters are versatile and widely used across industries for:

-

Metal Casting

- Filtering cast iron, ductile iron, copper, bronze, and brass.

- Reducing inclusion defects and improving casting quality.

-

High-Temperature Gas Filtration

- Filtering gases at elevated temperatures in industrial processes.

-

Chemical and Catalysis

- Serving as a carrier for catalysts or chemical fillings in high-temperature environments.

-

Environmental and Energy Applications

- Used in waste gas treatment and energy-saving processes.

Product Options

| Size (mm) | PPI (Pores Per Inch) | Application |

|---|---|---|

| 50 x 50 x 22 | 10–60 | Small-scale casting filtration |

| 100 x 100 x 22 | 10–60 | General metal casting |

| 300 x 300 x 22 | 10–60 | Large-scale filtration |

| Custom sizes | Available | Contact us for details |

Order Your Silicon Carbide Foam Filters Today

Contact Advanced Ceramic Materials (ACM) to learn more about Silicon Carbide Foam Filters or to request a custom quote. Improve your casting quality and process efficiency with ACM's advanced filtration solutions.