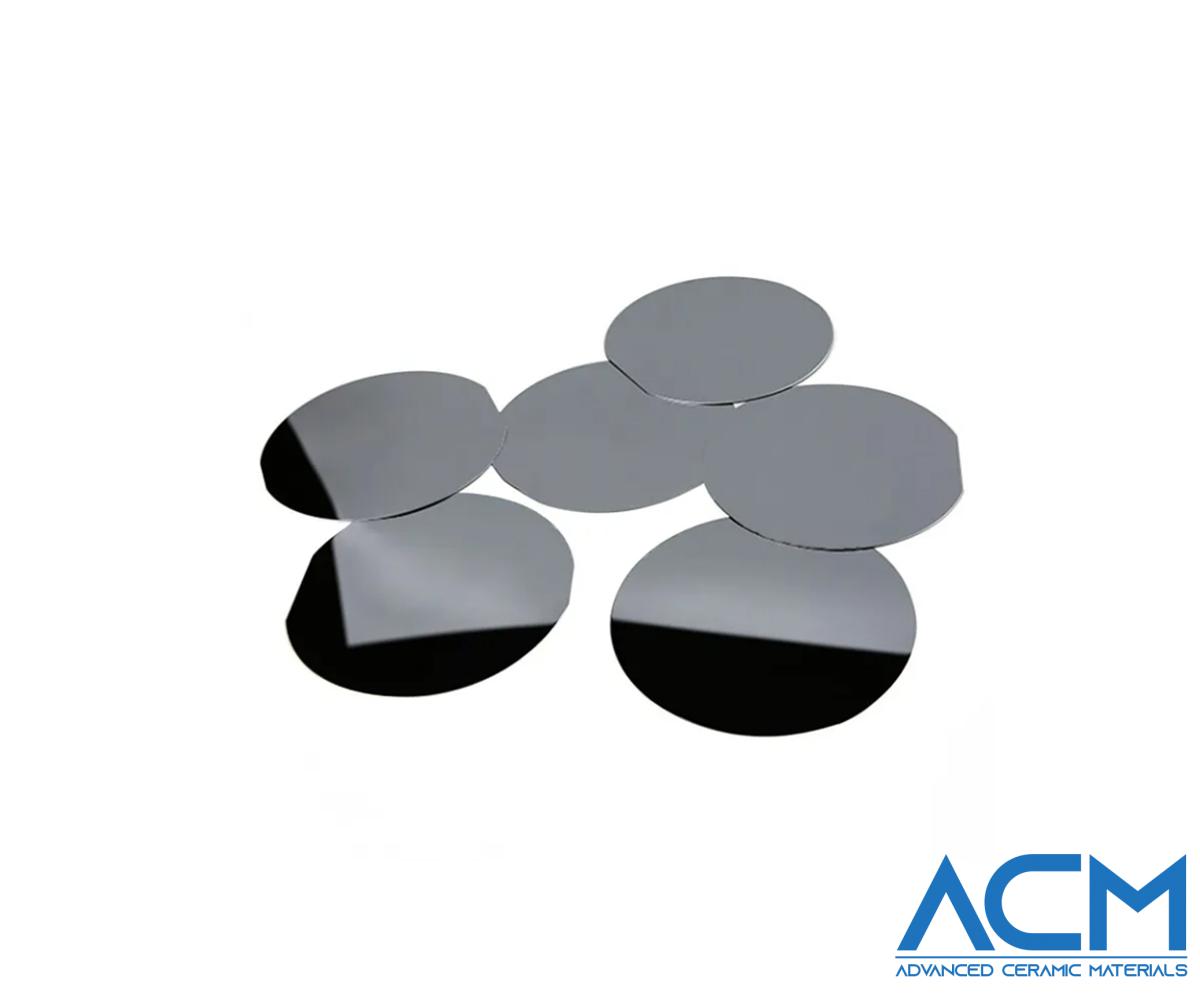

CY2426 Silicon Carbide (SiC) Crystal Substrates

- Catalog No. CY2426

- Size 10x10x0.33 mm or customized

- Surface Polished, One sides epi polished on Si face

- Orientation <0001> +/-0.5

- Growth Method MOCVD

Inquiry

CY2426 Silicon Carbide (SiC) Crystal Substrates

Silicon Carbide Crystal Substrates Description

Silicon Carbide Crystal Substrates, or SiC Crystals, possess a variety of crystal structures known as polytypes. Currently, the polytypes most actively explored for electronic applications include cubic 3C-SiC, hexagonal 4H-SiC and 6H-SiC, and rhombohedral 15R-SiC. These distinct polytypes are defined by the unique stacking sequence of the biatomic layers within the SiC structure.

Silicon Carbide Crystal Substrates Specifications

|

SiC crystal substrate |

|

|

Formula weight |

40.10 |

|

Lattice constant |

a =3.07 A c = 10.05 A |

|

Stacking sequence |

ABCB |

|

Growth Technique |

MOCVD |

|

Polishing |

Silicon face polished |

|

Band Gap |

3.26 eV ( Indirect) |

|

Resistivity |

0.01~0.5 ohm-cm |

|

Hardness |

9 Mohs |

|

The doping level of nitrogen atoms |

10^18-19 cm^-3 |

|

Surface Roughness |

< 10 A by AFM |

Silicon Carbide Crystal Substrates Applications

Silicon Carbide Crystal Substrates are utilized in a wide range of applications, including the deposition of III-V Nitrides, the creation of optoelectronic devices, and the development of high power, high-temperature, and high-frequency power devices.

Silicon Carbide Crystal Substrates Packing

Silicon Carbide Crystal Substrates are meticulously packaged to safeguard their quality and integrity during transportation and storage. These substrates are typically enclosed in protective materials to prevent any physical damage or contamination. They are then securely placed in robust, specially designed containers that accommodate their size and sensitivity, ensuring they remain intact and pristine throughout the shipping and handling process. This packaging approach is crucial for preserving the substrates' pristine condition, facilitating their safe arrival for industrial and research applications.

Request a Quote

-

Attachment (Optional)

No file chosen