Silicon Carbide Properties: A Summary

Introduction

Silicon Carbide (SiC), also known as carborundum, is a semiconductor material renowned for its exceptional thermal and mechanical properties. Discovered in 1891 by Pennsylvanian Edward Acheson, SiC has become one of the most important industrial ceramic materials. Its robust nature makes it ideal for applications in high-temperature, high-voltage, and abrasive environments. This article provides a comprehensive overview of the key properties of silicon carbide, emphasizing its role in modern technological applications and its historical significance in the industrial revolution.

Physical Properties of Silicon Carbide

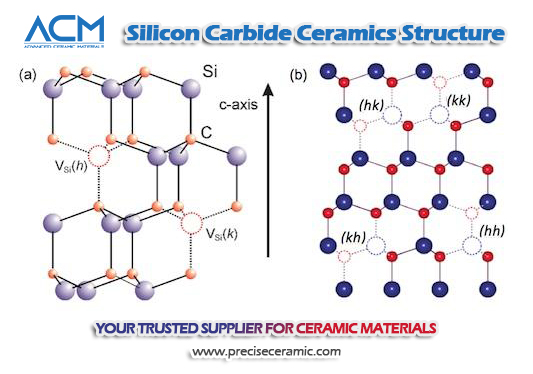

Silicon carbide is a distinct material characterized by its appearance as a black-grey to green powder or a solid grey form. This compound is noted for its lack of odor and a specific density of 3.21 g/cm³, positioning it as a denser material relative to common ceramics but less dense than some metals. Chemically, SiC is composed primarily of tetrahedral structures of silicon and carbon atoms, tightly bonded by strong covalent bonds within a crystal lattice. This unique structure imparts remarkable hardness, ranking SiC as the third hardest compound on Earth, with a Mohs hardness of 13 (new scale), just behind diamond and boron carbide. SiC is also insoluble in water, alcohol, and acids, underscoring its stability and inertness in various chemical environments.

Physical Characteristics Table:

| Property | Description/Value |

|---|---|

| Appearance | Black grey to green powder, grey solid |

| Odor | No odor |

| Specific Density | 3.21 g/cm³ |

| Mohs Hardness | 13 (new scale) |

| Composition | Tetrahedral structures of silicon and carbon |

| Crystal Structure | Strong covalent bonds in a crystal lattice |

| Solubility | Insoluble in water, alcohol, and acid |

These physical properties not only define the basic aspects of silicon carbide but also highlight its suitability for harsh environments, where materials are often exposed to aggressive chemical agents and conditions that may lead to corrosion in less robust materials. The combination of hardness and structural stability ensures that silicon carbide components can withstand some of the most challenging conditions, making it ideal for protective coatings, cutting tools, and other applications where durability and resistance to wear are critical.

Mechanical Properties of Silicon Carbide

Silicon carbide is exceptional for its mechanical properties, particularly its robust strength and durability. The material exhibits high fracture toughness, marked at 6.8 MPa m0.5, reflecting its resistance to crack propagation under stress. The Young's modulus of 440 GPa means SiC is very stiff and can retain its shape even under significant stress. The flexural strength is also notable at 490 MPa, showcasing SiC's bending resistance.

Moreover, SiC's hardness of 32 GPa situates it among the hardest materials known, with only diamond and boron carbide surpassing it in this regard. This hardness is crucial in applications requiring wear resistance and durability against extreme conditions.

Mechanical Properties Table:

| Property | Value |

|---|---|

| Fracture Toughness | 6.8 MPa m0.5 |

| Young's Modulus | 440 GPa |

| Flexural Strength | 490 MPa |

| Hardness | 32 GPa |

These properties make silicon carbide an ideal choice for applications in demanding environments, where mechanical loads and high pressures are prevalent. Industries such as aerospace, automotive, and defense benefit significantly from the use of SiC in their components due to its exceptional strength and resistance to deformation.

Thermal and Electrical Properties

Silicon carbide is highly valued for its exceptional thermal properties, including a high thermal conductivity of 120 W/m•K, which facilitates efficient heat dissipation. This is particularly advantageous in applications that operate under high temperatures or require rapid heat removal. SiC's low coefficient of thermal expansion (4.0 x10^–6/°C) also plays a crucial role by minimizing dimensional changes and maintaining structural integrity under temperature fluctuations.

Furthermore, silicon carbide possesses unique electrical properties, characterized by its semiconductor behavior. The electrical conductivity of SiC can be altered by the introduction of impurities (doping), which allows it to be tailored for various electronic applications, ranging from power devices to sensors.

Thermal and Electrical Properties Table:

| Property | Value |

|---|---|

| Thermal Conductivity | 120 W/m•K |

| Coefficient of Thermal Expansion | 4.0 x10–6/°C |

| Electrical Conductivity | Semiconductor, varies with dopant |

These properties make SiC an ideal material for components like heat exchangers, flame igniters, and semiconductor devices, which require high thermal stability and tailored electrical characteristics to perform efficiently and reliably in harsh environments.

Chemical Properties and Resistance

Silicon carbide is distinguished by its superior chemical inertness, making it exceptionally resistant to corrosion even in harsh chemical environments. This resistance is invaluable in industries where materials are exposed to corrosive substances, such as in the manufacturing of chemicals or in applications involving harsh mechanical processes.

SiC's ability to withstand high temperatures up to 1600°C in air is further enhanced by its formation of a protective silicon oxide coating at 1200°C, which shields the material from oxidation and other chemical reactions. This stability is crucial for applications that operate under extreme conditions, preventing degradation that could compromise functionality and safety.

Chemical Properties and Resistance Table:

| Property | Description |

|---|---|

| Chemical Stability | Resistant to acids, alkalis, and molten salts up to 800°C |

| Protective Coating | Forms silicon oxide coating at 1200°C that protects up to 1600°C |

| Corrosion Resistance | High, against a wide range of chemicals |

Silicon carbide's chemical durability also enables its use in semiconductor manufacturing and other high-tech applications, where purity and resistance to chemical reactions are critical. The material’s ability to resist chemical attack ensures long-lasting performance and reliability in challenging operational environments.

Conclusion

Silicon Carbide (SiC) stands out as a material with remarkable properties that span across physical, mechanical, thermal, and chemical domains. Its combination of hardness, thermal stability, and chemical inertness makes it a prime choice for high-performance applications subjected to extreme conditions. The ability of SiC to maintain its integrity at high temperatures, resist chemical and thermal shocks, and display significant mechanical strength under pressure showcases its versatility and indispensable role in modern technology and industrial applications.

Companies like Advanced Ceramic Materials (ACM) play a crucial role as suppliers of high-quality silicon carbide and other ceramic materials, supporting a wide range of industries in harnessing these advanced properties for cutting-edge applications.

By exploring the unique properties of silicon carbide, we gain insight into its pivotal contributions to advancements in sectors ranging from aerospace to electronics and beyond. As technology continues to evolve, the reliance on materials like SiC is likely to increase, further underscoring its importance in future innovations.

Further Reading

For those interested in delving deeper into the properties and applications of silicon carbide, the following resources are highly recommended:

- An Overview of Silicon Carbide Ceramic Materials: This article provides a comprehensive introduction to the characteristics and benefits of silicon carbide ceramics. Read more.

- What Are the Uses of Silicon Carbide?: Explore the diverse applications of silicon carbide in various industries, demonstrating its versatility and importance. Read more.

- Main Production Methods of Silicon Carbide Ceramics: Gain insight into the different methods used to produce silicon carbide ceramics, a crucial aspect for understanding its various forms and uses. Read more.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments