BN6259 Cubic Boron Nitride Powder (cBN)

- Catalog No. BN6259

- CAS Number 10043-11-5

- Morphology Cubic

- Particle Size 0.1-80 μm

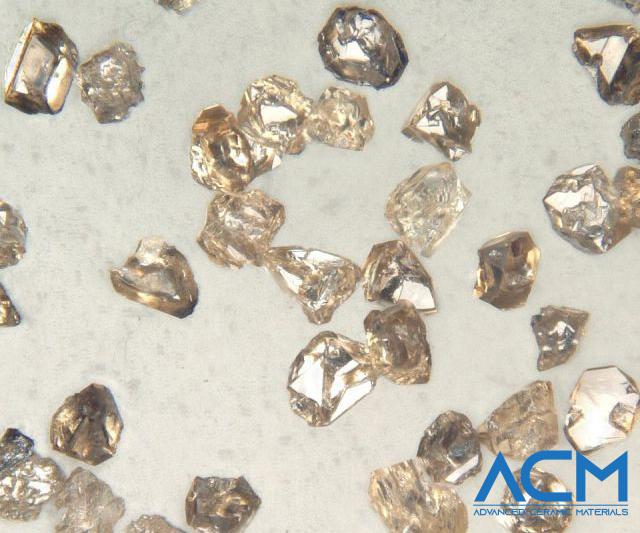

- Form Brown crystalline powder

- Purity ≥99.5%

BN6259 Cubic Boron Nitride Powder (cBN)

Overview of Cubic Boron Nitride Powder (cBN)

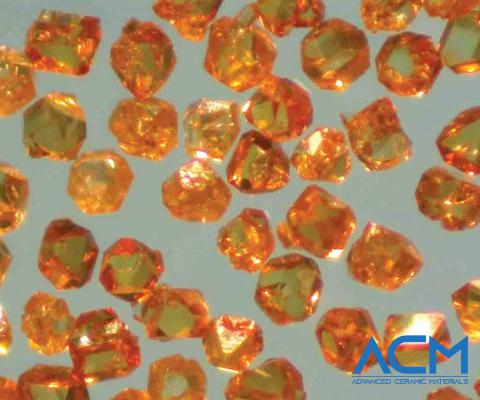

Cubic Boron Nitride Powder (cBN) is a finely ground form of cubic boron nitride, one of the hardest synthetic materials, second only to diamond in hardness. Composed of uniformly sized cBN particles, this powder retains the material's inherent properties, including exceptional hardness, excellent thermal stability, and strong chemical resistance. Compared to traditional abrasives such as aluminum oxide and silicon carbide, cBN offers superior wear resistance, thermal conductivity, and hardness. These characteristics make cBN powder ideal for various industrial applications, including abrasive processes, coating technologies, and precision machining.

Specifications of Cubic Boron Nitride Powder (cBN)

|

CAS Number |

10043-11-5 |

|

Chemical Formula |

BN |

|

Morphology |

Cubic |

|

Particle Size |

0.1-80 μm |

|

Form |

Orange powder |

|

Melting Point |

2527℃ |

|

Density |

2.29 g/cm3 |

|

Purity |

≥99.5% |

Applications of Cubic Boron Nitride Powder (cBN)

-

Abrasive and Grinding Tools: cBN powder is extensively used in the production of grinding wheels, honing tools, and abrasive pastes, particularly for high-precision machining of hardened steels, superalloys, and other materials that are difficult to machine.

-

Polishing: With its uniform particle size and extreme hardness, cBN powder is ideal for achieving high-quality finishes. It ensures even material removal and creates smooth, polished surfaces on hard materials like ceramics and metals.

-

Wear-Resistant Coatings: cBN powder is used to formulate thin wear-resistant coatings for cutting tools and other components, significantly improving their resistance to wear and extending their operational lifespan in demanding conditions.

-

Thermal Management in Electronics: Due to its high thermal conductivity, cBN powder is sometimes incorporated into polymer composites or coatings for thermal management applications in electronics, helping to dissipate heat efficiently and improve device reliability.

Packaging and Handling

Our Cubic Boron Nitride Powder (cBN) is carefully handled during storage and transportation to maintain the quality of the product and ensure it arrives in its original condition.