BN6258 Cubic Boron Nitride Particles (cBN)

- Catalog No. BN6258

- CAS Number 10043-11-5

- Chemical Formula BN

- Particle Size <1mm

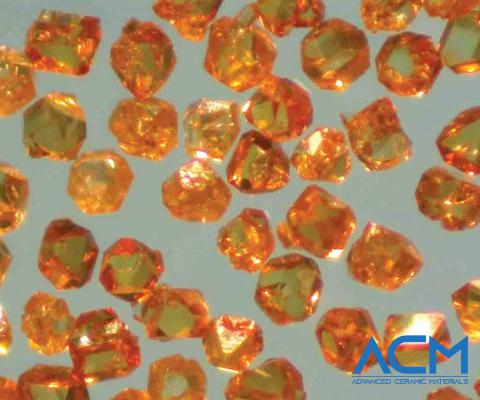

- Form Orange transparent particles

- Purity ≥99.5%

BN6258 Cubic Boron Nitride Particles (cBN)

Overview of Cubic Boron Nitride Particles (cBN)

Cubic Boron Nitride (cBN) Particles are synthetic boron nitride particles characterized by a cubic crystalline structure, similar to that of diamond. As one of the hardest materials on Earth—second only to diamond—cBN is highly regarded for its exceptional hardness, excellent thermal stability, and outstanding chemical resistance. These properties make cBN particles ideal for demanding industrial applications where high wear resistance, superior thermal conductivity, and durability in extreme environments are required.

Specifications of Cubic Boron Nitride Particles (cBN)

|

CAS Number |

10043-11-5 |

|

Chemical Formula |

BN |

|

Synonym |

Cubic Boron Nitride, cBN |

|

Particle Size |

<1mm |

|

Form |

Orange transparent particles |

|

Purity |

≥99.5% |

Applications of Cubic Boron Nitride Particles (cBN)

-

Cutting and Grinding Tools: cBN particles are extensively used in the manufacturing of cutting and grinding tools for hard-to-machine materials like hardened steel, cast iron, and superalloys. These tools include drills, saw blades, and grinding wheels, providing precision and durability.

-

Abrasive Polishing: These particles are employed as abrasives in precision polishing applications, delivering a smooth, high-quality finish on hard materials like ceramics, glass, and metal alloys.

-

Wear-Resistant Coatings: cBN is used in creating wear-resistant coatings for industrial tools and machinery components, enhancing their lifespan and ensuring they maintain peak performance in abrasive environments.

-

Electronics and Heat Management: Due to their high thermal conductivity, cBN particles are sometimes integrated into thermal management systems for electronics, helping to dissipate heat and improve device performance.

Packaging and Handling

Our Cubic Boron Nitride Particles (cBN) are carefully stored and transported to maintain the product's quality and ensure that it reaches you in its original condition.