Do you have any questions? Email Us

[email protected]

Ceramic Material Comparison Chart

Explore our interactive ceramic material comparison chart below, designed to help you easily compare different materials based on their key properties, and find the best fit for your application.

READ MORE >

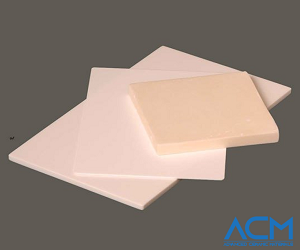

AL1824 Light Mullite Brick

Light Mullite Brick Description

Light Mullite Brick, composed primarily of aluminum raw materials integrated with cordierite or mullite, ensures superior compressive strength, thermal shock resistance, and a minimal thermal expansion coefficient. These bricks are characterized by their exceptionally low iron and alkali metal content, contributing to their high refractoriness. The elevated aluminum content enhances their performance, particularly in reduced atmospheres. They are precisely dimensioned for masonry, featuring thin and uniform bricks that contribute to a structure's high strength and stability.

Light Mullite Brick Specifications

|

Type |

MB-35 |

MB-38 |

|

Max Service Temperature |

1260 °C |

1350 °C |

|

Al2O3 |

50% |

55% |

|

Fe2O3 |

1.2% |

1.2% |

|

Bulk Density |

0.6 g/cm3 |

0.8 g/cm3 |

|

Cold Compressive Strength |

1.3 Mpa |

2.0 Mpa |

Light Mullite Brick Application

Light Mullite Brick serves effectively as a supportive insulation layer for the hot surface refractory linings or alongside other refractory materials. It finds extensive use in various thermal processing equipment such as melting furnaces, firing kilns, flues, refining apparatus, heating devices, regenerators, gas generators, and pipelines. Additionally, it is suitable for use in soaking furnaces, annealing furnaces, reaction chambers, and a wide range of similar industrial thermal machinery.

Light Mullite Brick Packaging

Our Light Mullite Bricks are carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Request a Quote

-

Attachment (Optional)

No file chosen

I would like to join the mailing list to receive updates from Advanced Ceramic Materials .

*e-mail address with your company's domain name is preferred. Otherwise, we may not be able to process your inquiry.

Tel : (949) 407-8904

Address : 1940 E Deere Ave #100 Santa Ana, CA 92705 U.S.A.

Main Products

Useful Links

Featured Posts

Search

Copyright © 1994-2025 Advanced Ceramic Materials owned by Oceania International LLC, All Rights Reserved.