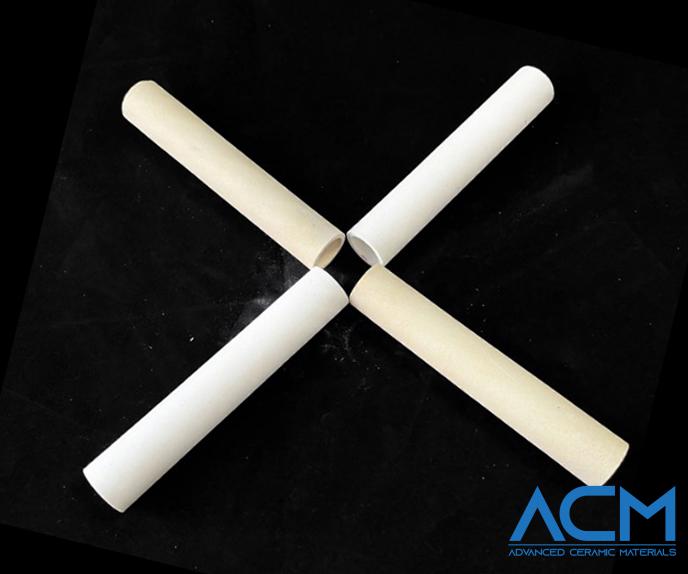

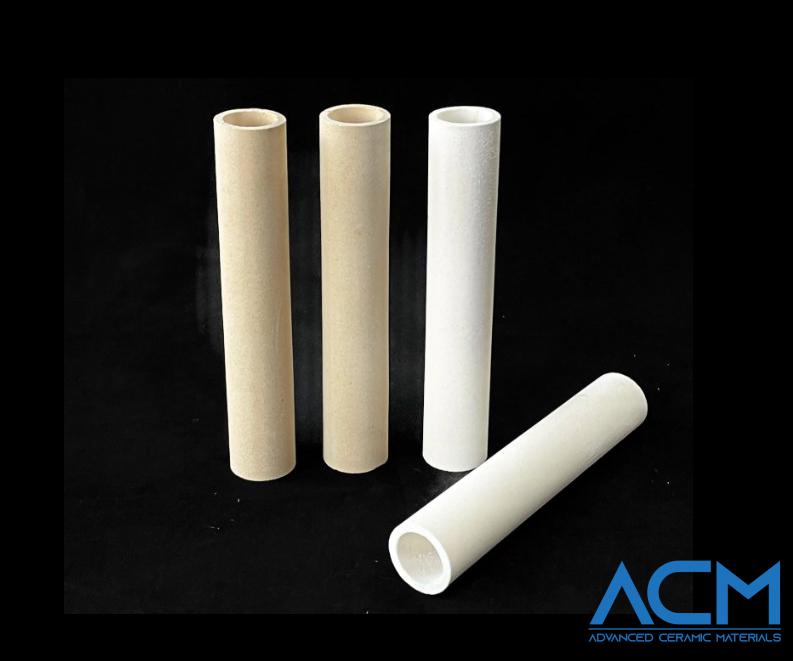

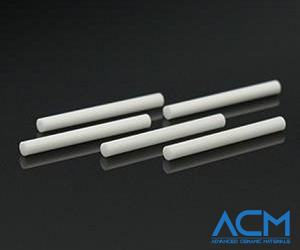

MC2251 Mullite Tube, Silicate Ceramic Tube

- Catalog No. MC2251

- Color Off-white

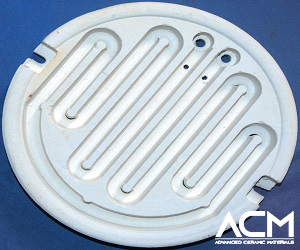

- Shape Heater Plate

- Thermal Conductivity 6 W/m·K

- Dielectric Strength 9.8 ac-kv/mm

Datasheet

Inquiry

MC2251 Mullite Tube, Silicate Ceramic Tube

Mullite Tube Description

Advanced Ceramic Materials (ACM) offers high-quality Mullite Tubes, made from silicate ceramic mullite. The primary crystal phase of mullite is 3Al2O3·2SiO2, known for its low thermal expansion, excellent mechanical strength, and resilience at elevated temperatures. Mullite is a vital material in both conventional and advanced ceramics due to its availability, affordability, and workability, allowing for extensive range and flexibility in fabrication.

Mullite Tube Specifications

| Chemistry Content of Mullite Tube | |||||||||

| Al2O3 | SiO2 | TiO2 | Fe2O3 | CaO·MgO | K2ONa2O and others | ||||

| 62.50% | 34.50% | 0.10% | 0.80% | 0.90% | 1.30% | ||||

Mechanical Properties

| Property | Units | Value |

|---|---|---|

| Density | gm/cc | 2.8 |

| Porosity | % | 0 |

| Flexural Strength | MPa | 180 |

| Elastic Modulus | GPa | 151 |

| Compressive Strength | MPa | 1310 |

| Hardness | Kg/mm² | 1070 |

| Fracture Toughness KIC | MPa·m¹/² | 2 |

| Maximum Use Temperature (no load) | °C | 1650 |

Thermal Properties

| Property | Units | Value |

|---|---|---|

| Thermal Conductivity | W/m·K | 6 |

| Coefficient of Thermal Expansion | 10⁻⁶/°C | 5.4 |

Electrical Properties

| Property | Units | Value |

|---|---|---|

| Dielectric Strength | ac-kv/mm | 9.8 |

| Dielectric Constant (@ 1 MHz) | - | 5.8 |

| Dissipation Factor (@ 1 kHz) | - | 0.003 |

| Volume Resistivity | ohm·cm | >10¹³ |

Key Features and Benefits

- High Thermal Stability: Can withstand high temperatures up to 1650°C.

- Excellent Mechanical Strength: High compressive and flexural strength.

- Low Thermal Expansion: Reduces the risk of thermal shock.

- High Dielectric Strength: Ideal for electrical insulation applications.

- Cost-Effective: Raw materials are affordable and readily available.

Applications

Mullite ceramic tubes have a wide variety of applications, including:

- Machining Components and Tooling: Suitable for various machining tasks.

- Protection Tubes: Used in high-temperature environments.

- Prototyping: Ideal for creating prototypes.

- Small Ceramic Series Manufacturing: Suitable for manufacturing small ceramic parts.

- Coil Cores and Electrical Insulators: Used in electrical applications.

- Injectors and Nozzles: Suitable for high-temperature injectors and nozzles.

- Vacuum Parts: Used in vacuum systems.

- Thermal and Inductive Insulators: Provides excellent thermal insulation.

- Brazing and Welding Templates: Used as templates for brazing and welding.

- Sensors: Ideal for sensor applications.

Packaging and Quality Assurance

ACM’s Mullite Tubes are carefully handled to minimize damage during storage and transportation, ensuring the products remain in their original high-quality condition.

Frequently Asked Questions (FAQs)

-

What is the maximum operating temperature for Mullite Tubes?

- Our Mullite Tubes can withstand temperatures up to 1650°C.

-

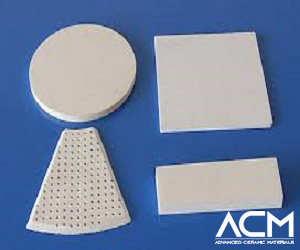

Do you offer custom sizes and shapes?

- Yes, we offer custom sizes and shapes to meet specific requirements. Please contact us for more details.

-

What are the typical applications for Mullite Tubes?

- Mullite Tubes are used in machining components, protection tubes, prototyping, small ceramic series manufacturing, coil cores, electrical insulators, injectors, nozzles, vacuum parts, thermal insulators, brazing and welding templates, and sensors.

Discover More

- Other Mullite Products: Explore our range of mullite products.

- Latest Post: Read our latest article on ceramic materials.

- Contact Us: Get in touch or request a quote for more information.

Request a Quote

-

Attachment (Optional)

No file chosen