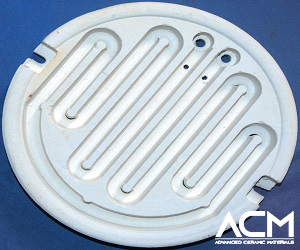

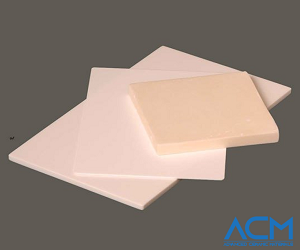

MC2247 Mullite Heater Plate, Silicate Heater Plate

- Catalog No. MC2247

- Color Off-white

- Shape Heater Plate

- Thermal Conductivity 6 W/m·K

- Dielectric Strength 9.8 ac-kv/mm

Datasheet

Inquiry

MC2247 Mullite Heater Plate, Silicate Heater Plate

Mullite Heater Plate Description

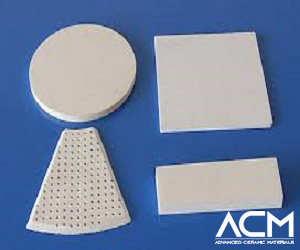

Mullite heater plate is made of silicate ceramic mullite (3Al2O32SiO2). Mullite is a refractory oxide material combining low thermal expansion, good mechanical strength, and resilience at elevated temperatures. Raw mullite materials are easily obtained and reasonably priced. It is certainly one of the most important oxide materials for both conventional and advanced ceramics. Its workability allows an extensive range and flexibility in fabrication.

Advanced Ceramic Materials (ACM) is a trusted supplier of mullite ceramic products.

Mullite Heater Plate Specifications

| Chemistry Content | |||||||||

| Al2O3 | SiO2 | TiO2 | Fe2O3 | CaO·MgO | K2ONa2O and others | ||||

| 62.50% | 34.50% | 0.10% | 0.80% | 0.90% | 1.30% | ||||

| Mechanical | Units of Measure | SI/Metric | (Imperial) |

| Density | gm/cc (lb/ft3) | 2.8 | -175 |

| Porosity | % (%) | 0 | 0 |

| Color | – | off-white | off-white |

| Flexural Strength | MPa (lb/in2x103) | 180 | -26 |

| Elastic Modulus | GPa (lb/in2x106) | 151 | -22 |

| Shear Modulus | GPa (lb/in2x106) | – | – |

| Bulk Modulus | GPa (lb/in2x106) | – | – |

| Compressive Strength | MPa (lb/in2x103) | 1310 | -190 |

| Hardness | Kg/mm2 | 1070 | – |

| Fracture Toughness KIC | MPa?m1/2 | 2 | – |

| Maximum Use Temperature | °C (°F) | 1650 | -3000 |

| (no load) | |||

| Thermal | |||

| Thermal Conductivity | W/m?°K (BTU?in/ft2?hr?°F) | 6 | -42 |

| Coefficient of Thermal Expansion | 10–6/°C (10–6/°F) | 5.4 | -3 |

| Electrical | |||

| Dielectric Strength | ac-kv/mm (volts/mil) | 9.8 | -245 |

| Dielectric Constant | @ 1 MHz | 5.8 | 5.8 |

| Dissipation Factor | @ 1 kHz | 0.003 | 0.003 |

| Volume Resistivity | ohm?cm | >1013 | >1013 |

Mullite Heater Plate Applications

Mullite heater plates have the following applications:

- Machining of components and toolings

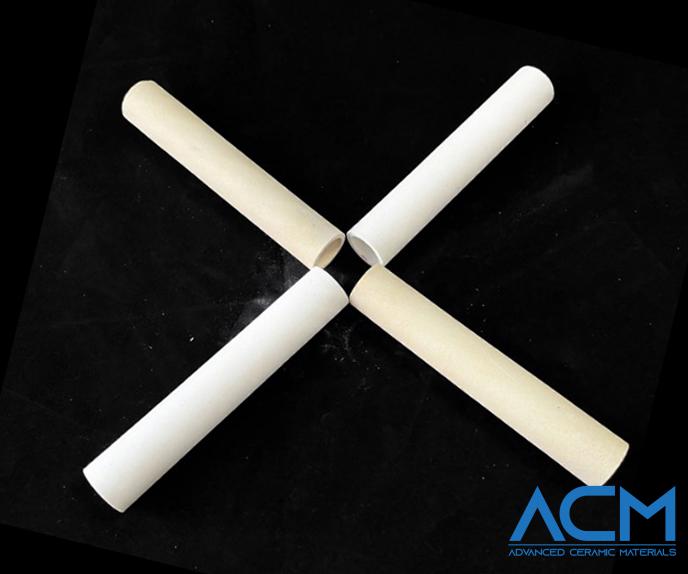

- Protection tubes

- Realization of prototypes

- Manufacturing of small ceramic series

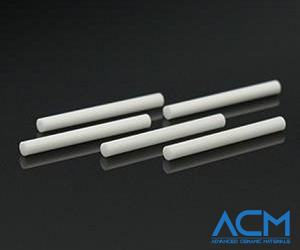

- Coil cores

- Electrical insulator

- Template of assembly

- Injectors, nozzles

- Vacuum parts

- Thermal insulators, inductive insulators

- Template of brazing and welding

- Sensors

Request a Quote

-

Attachment (Optional)

No file chosen