Do you have any questions? Email Us

[email protected]

Ceramic Material Comparison Chart

Explore our interactive ceramic material comparison chart below, designed to help you easily compare different materials based on their key properties, and find the best fit for your application.

READ MORE >

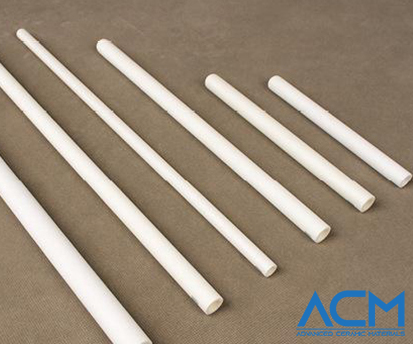

ZR3130 Magnesia Stabilized Zirconia Tube

Magnesia Stabilized Zirconia Tube Description

The Magnesia Stabilized Zirconia Tube stands as a robust ceramic material designed for use in demanding service applications. It demonstrates exceptional resilience against thermal shock and erosion, showcasing low thermal expansion properties and excellent non-wetting characteristics. Zirconia (ZrO2) tubes serve as highly effective refractory and insulating materials, particularly in applications involving the melting of superalloys and precious metals at temperatures exceeding 1900°C. With a clean melt process, these tubes exhibit outstanding chemical inertness, superior thermal shock resistance up to 2200°C, and reliable corrosion resistance to acids and alkalis.

Magnesia Stabilized Zirconia Tube Specifications

| Composition | ZrO2 | MgO | CaO | Al2O3 | TiO2 | Fe2O3 | SiO2 |

| Content % | 95.3 | 2.2 | 0.2 | 0.7 | 0.2 | 0.2 | 1.2 |

|

Physical Properties |

|

|

Density |

4.5g/cc |

|

Porosity |

18% |

|

MOR @R.T. |

3500psi |

Magnesia Stabilized Zirconia Tube Applications

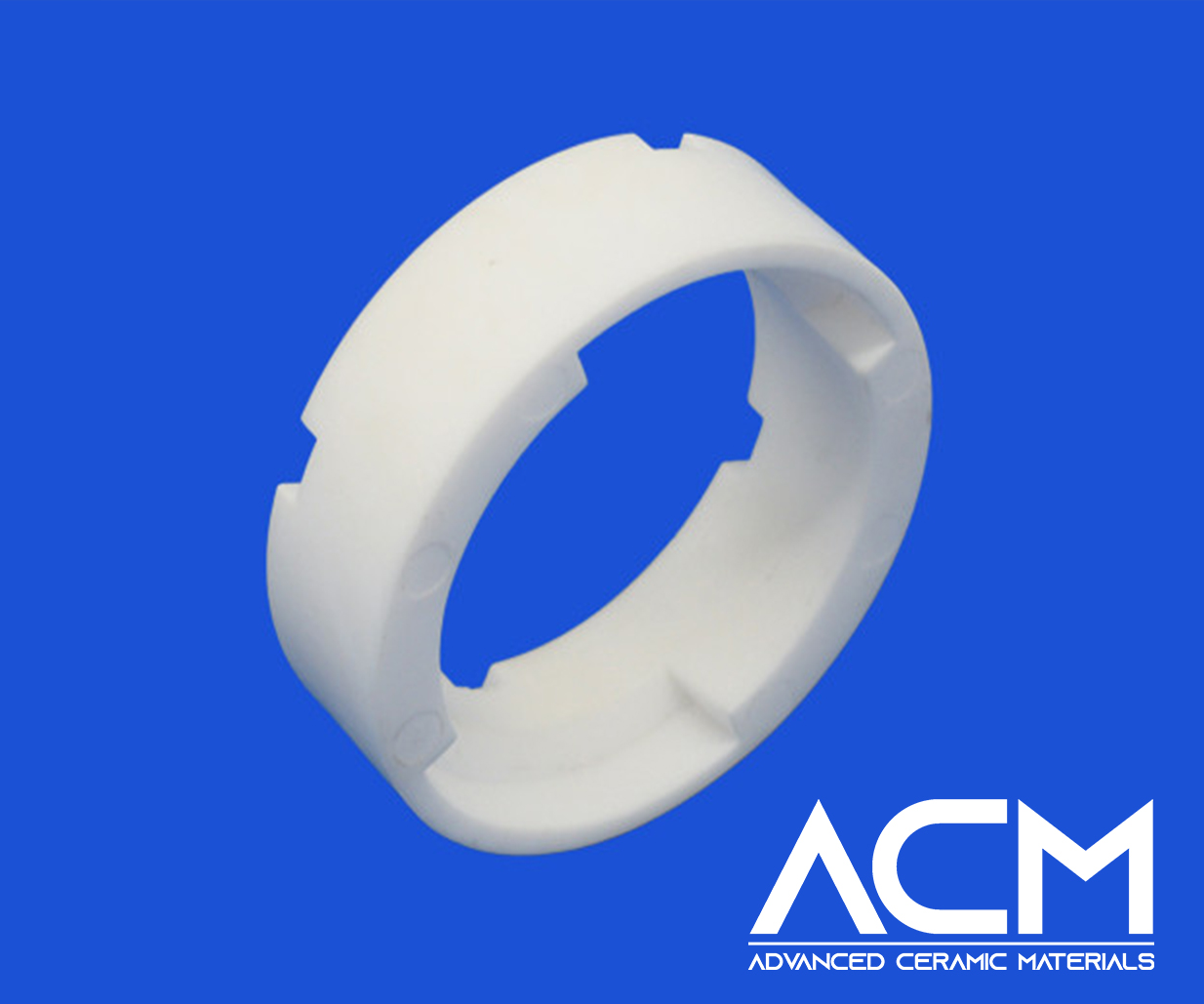

Magnesia Stabilized Zirconia Tubes exhibit versatility across various industries, proving invaluable as shafts, plungers, and sealing structures. Their durability and resilience make them essential components in the automotive industry, oil drilling equipment, and insulating elements in electrical equipment. Beyond industrial use, these tubes demonstrate their exceptional properties in everyday items, serving as ceramic knives and spare parts for ceramic hair clippers.

Magnesia Stabilized Zirconia Tube Packaging

Our high-purity Magnesia Stabilized Zirconia Tube is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Request a Quote

-

Attachment (Optional)

No file chosen

I would like to join the mailing list to receive updates from Advanced Ceramic Materials .

*e-mail address with your company's domain name is preferred. Otherwise, we may not be able to process your inquiry.

Tel : (949) 407-8904

Address : 1940 E Deere Ave #100 Santa Ana, CA 92705 U.S.A.

Main Products

Useful Links

Featured Posts

Search

Copyright © 1994-2025 Advanced Ceramic Materials owned by Oceania International LLC, All Rights Reserved.