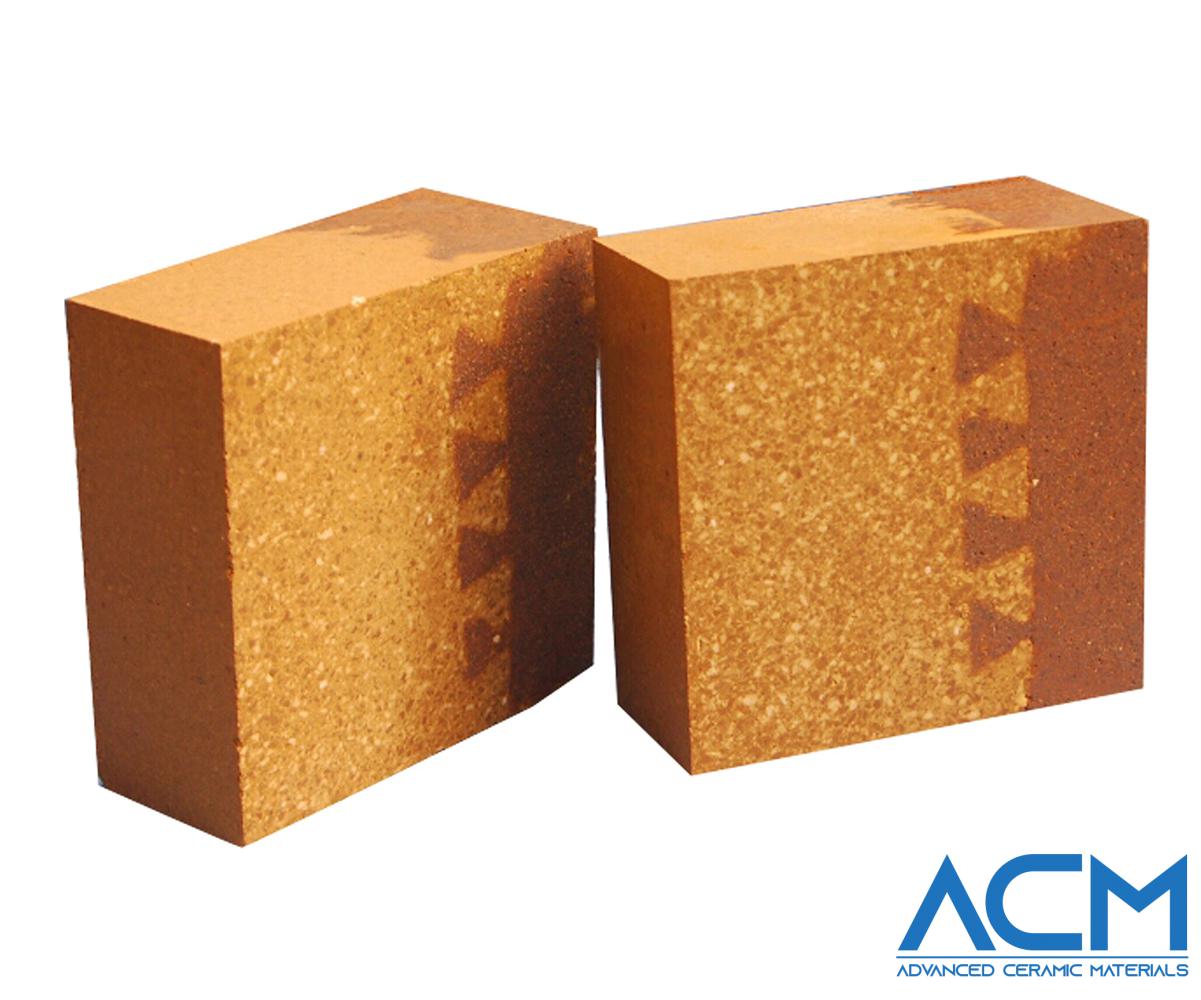

MC6251 Silica Mullite Wear-resistant Composite Brick

- Catalog No. MC6251

- Material Al2O3, SiC, SiO2

- Bulk Density 2.65 g/cm3

- Content Al2O3 ≥50%

- Max Working Temp. 1300℃

Inquiry

MC6251 Silica Mullite Wear-resistant Composite Brick

Overview of Silica Mullite Wear-resistant Composite Brick

Silica Mullite Wear-resistant Composite Bricks are advanced refractory bricks engineered for exceptional wear resistance and durability in high-temperature applications. Constructed from a blend of silica (SiO₂) and mullite (3Al₂O₃·2SiO₂), these bricks offer impressive thermal stability, mechanical strength, and resistance to chemical corrosion. Their unique composition makes them ideal for high-wear environments where protection against mechanical abrasion, thermal shock, and chemical erosion is essential, such as in rotary and cement kilns.

Silica Mullite Wear-resistant Composite Brick Specifications

|

Items |

GMF-1 |

|

|

Structure |

Working layer |

Thermal insulation layer |

|

Al2O3, % ≥ |

65 |

50 |

|

SiC+SiO2, ≥ |

30 |

- |

|

Bulk Density g/cm3 ≥ |

2.65 |

2.1-2.3 |

|

Apparent Porosity % ≤ |

17 |

- |

|

Cold Crushing Strength Mpa ≥ |

90 |

50 |

|

Thermal Shock Resistance 800℃ water cycle ≥ |

15 |

15 |

|

Wear Resistance A/C ≥ |

5 |

- |

|

Thermal Conductivity 800℃ w·m·k |

2.5-2.3 |

1.0-1.3 |

Applications of Silica Mullite Wear-resistant Composite Bricks

- Cement Kilns: Frequently used in the transition and cooling zones of cement rotary kilns, these bricks provide superior wear resistance and stability at high temperatures.

- Rotary Kilns: Suitable for various types of rotary kilns, particularly in the sintering zone, where high abrasion and chemical resistance are critical.

- Non-ferrous Metal Furnaces: Ideal for areas in copper and aluminum melting furnaces that encounter high temperatures and exposure to corrosive slags.

Packaging and Handling

Our Silica Mullite Wear-resistant Composite Bricks are carefully packaged and handled to maintain their quality and ensure they reach you in optimal condition.

Frequently Asked Questions (FAQs)

Q1: What is a Silica Mullite Wear-resistant Composite Brick?

This is a refractory brick crafted from a combination of silica (SiO₂) and mullite (3Al₂O₃•2SiO₂), specifically designed to resist high wear, thermal shock, and chemical erosion in extreme-temperature environments.

Q2: Where are Silica Mullite Composite Bricks typically used?

These bricks are primarily used in cement kilns, particularly in transition and cooling zones, as well as in rotary kilns and non-ferrous metal furnaces, where resistance to abrasion, heat, and chemicals is crucial.

Q3: How are Silica Mullite Composite Bricks manufactured?

These bricks are produced by combining high-quality silica with mullite under carefully controlled firing conditions. This process bonds the materials into a dense, wear-resistant brick capable of withstanding high temperatures and mechanical stress.

Request a Quote

-

Attachment (Optional)

No file chosen