(Discontinued) AC2691 Alumina Ceramic Honeycomb

- Catalog No. AC2691

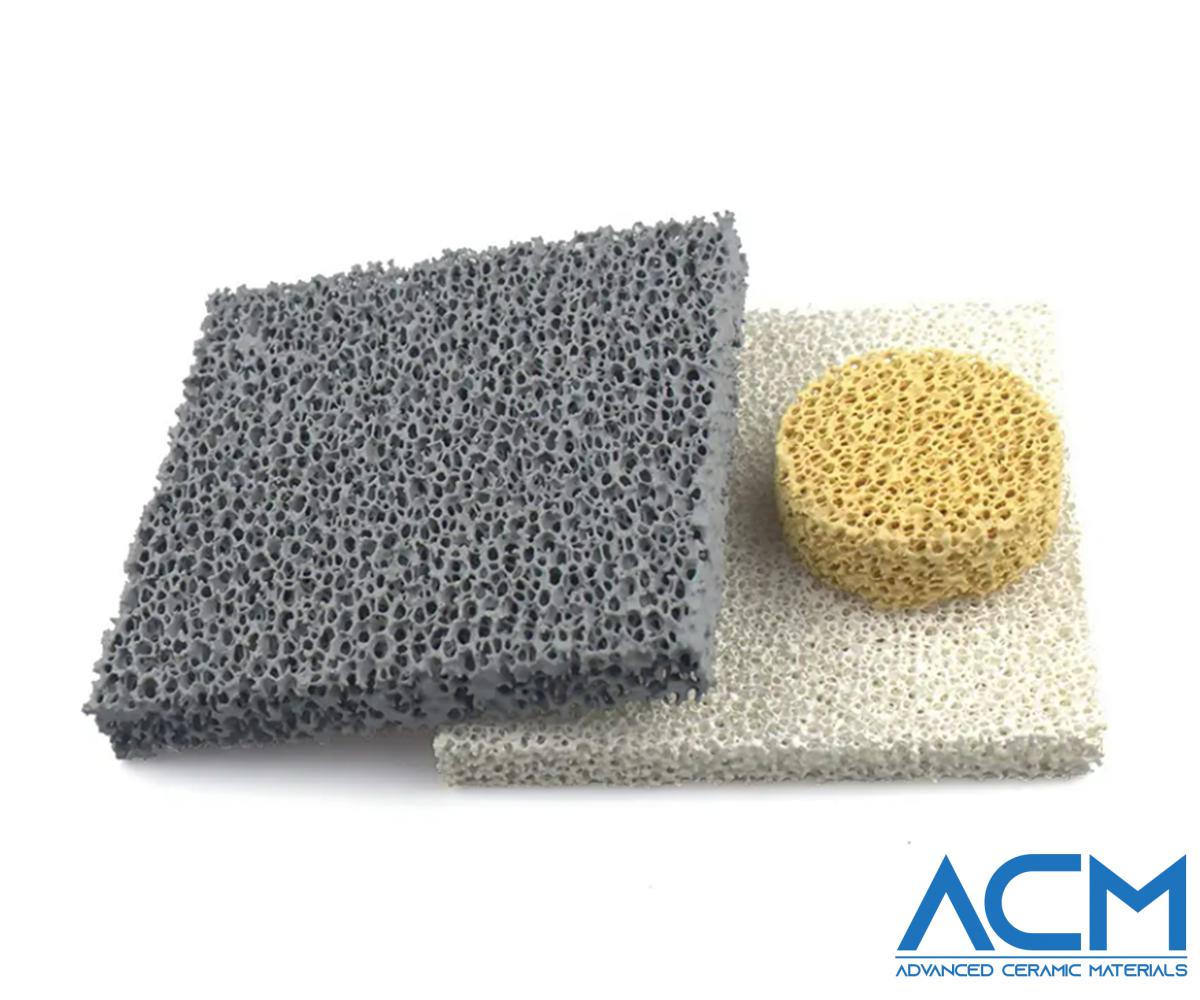

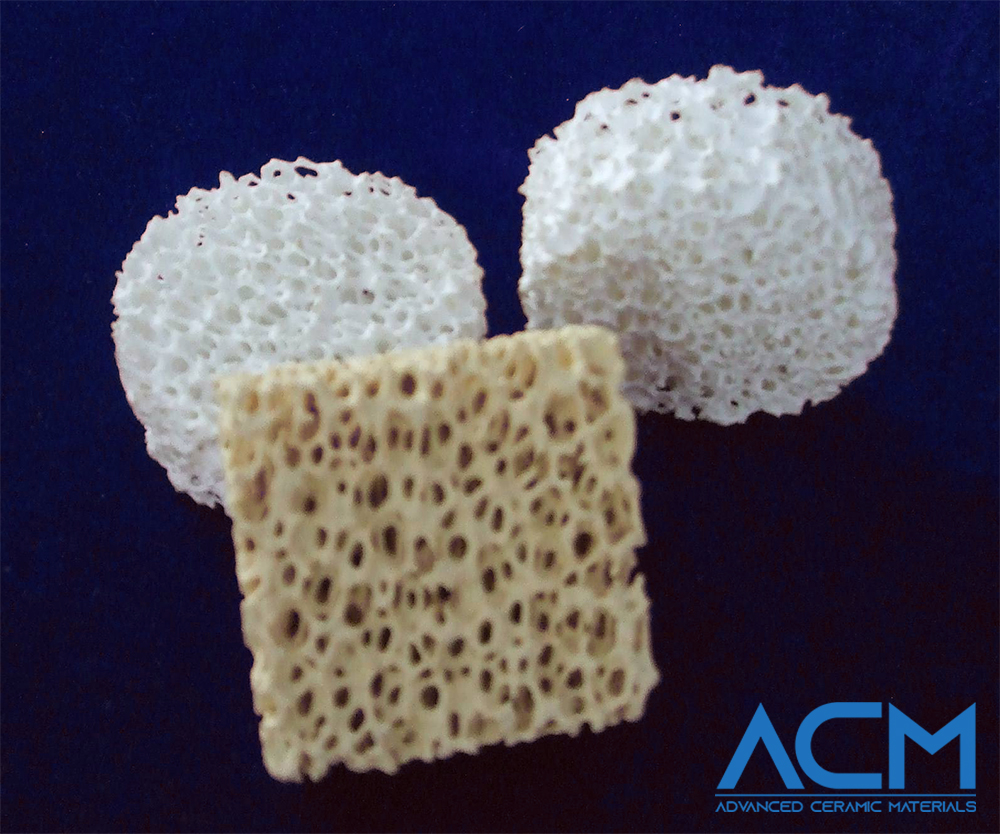

- Color Ivory/White

- Compositions Al2O3

- Working Temperature ≤1750℃

- Hole Type Round/Square

Datasheet

Inquiry

(Discontinued) AC2691 Alumina Ceramic Honeycomb

Discontinued

Alumina Ceramic Honeycomb Description

Alumina Ceramic Honeycomb is made of alumina ceramic. Alumina is a ceramic material with high thermal conductivity, compressive strength, and thermal shock resistance. It also has a low thermal expansion, making it also a suitable material for furnace use in the crucible, tube, and thermocouple sheath form. Honeycomb ceramic is a new type of ceramic product with a structure similar to a honeycomb shape. It is widely used in chemical, electric power, metallurgy, petroleum, electronic appliances, machinery, and other industries.

Alumina Ceramic Honeycomb Specifications

|

Properties |

Units |

Test |

Value |

|

Physical |

|||

|

Chemical Formula |

– |

– |

Al2O3 |

|

Density, ρ |

g/cm3 |

ASTM C20 |

3.7-3.97 |

|

Color |

– |

– |

ivory/white |

|

Crystal Structure |

– |

– |

hexagonal |

|

Water Absorption |

% @R.T. |

ASTM C373 |

0.0 |

|

Hardness |

Moh’s |

– |

9 |

|

Hardness |

knoop (kg/mm2) |

Knoop 100g |

2000 |

|

Mechanical |

|||

|

Compressive Strength |

MPa @ R.T. |

ASTM C773 |

2070-2620 |

|

Tensile Strength |

MPa @ R.T. |

ACMA Test #4 |

260-300 |

|

Modulus of Elasticity |

GPa |

ASTM C848 |

394 |

|

Flexural Strength (MOR) |

MPa @ R.T. |

ASTM F417 |

310-379 |

|

Poisson’s Ratio, ν |

– |

ASTM C818 |

0.27 |

|

Fracture Toughness, KIc |

MPa x m1/2 |

Notched Beam Test |

4.5 |

|

Thermal |

|||

|

Max. Use Temperature |

ºC |

No load cond. |

1750 |

|

Thermal Shock Resistance |

ΔT (ºC) |

Quenching |

200 |

|

Thermal Conductivity |

W/m-K @ R.T. |

ASTM C408 |

35 |

|

Coefficient of Linear Thermal Expansion, αl |

µm/m-ºC (~25ºC through ±1000ºC) |

ASTM C372 |

8.4 |

|

Specific Heat, cp |

cal/g-ºC @ R.T. |

ASTM C351 |

0.21 |

|

Electrical |

|||

|

Dielectric Constant |

1MHz @ R.T. |

ASTM D150 |

9.6 |

|

Dielectric Strength |

kV/mm |

ASTM D116 |

15 |

|

Electrical Resistivity |

Ω cm @ R.T. |

ASTM D1829 |

>1014 |

Alumina Ceramic Honeycomb Chemical Composition

|

SiO2% |

50.9±1 |

|

Al2O3% |

35.2±1 |

|

MgO% |

13.9±1 |

Alumina Ceramic Honeycomb Applications

- Chemical

- Electric power

- Metallurgy

- Petroleum

- Electronic appliances

- Machinery

Request a Quote

-

Attachment (Optional)

No file chosen