Hexagonal Boron Nitride (HBN)

Hexagonal boron nitride (HBN), a typical form of boron nitride ceramics often dubbed "white graphite," is a white powder known for its similarity to graphite in both crystal structure and physicochemical properties. With outstanding electrical insulation, high thermal conductivity, and chemical resistance, HBN finds versatile applications across industries. Its low density, high-temperature stability, and chemical inertness make it a favored choice for lightweight, heat-efficient, and chemically stable materials.

HBN's unique combination of properties positions it as a valuable material for diverse applications. Its low density and excellent thermal conductivity suit it for lightweight components with efficient heat dissipation needs, while its chemical inertness ensures stability in the presence of organic solvents and corrosive chemicals. The high-temperature stability of HBN adds to its utility, making it a dependable option in environments with extreme conditions. Whether in electronics, chemical engineering, or materials science, hexagonal boron nitride continues to stand out as a versatile and reliable material.

Products | Structures | Specification | Applications | Video | FAQs | Product Brochure

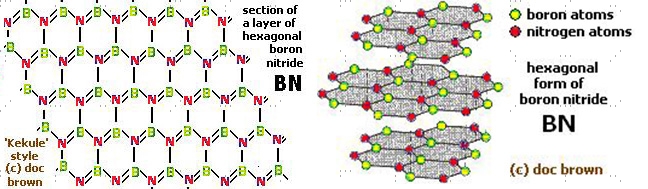

Hexagonal Boron Nitride Structure

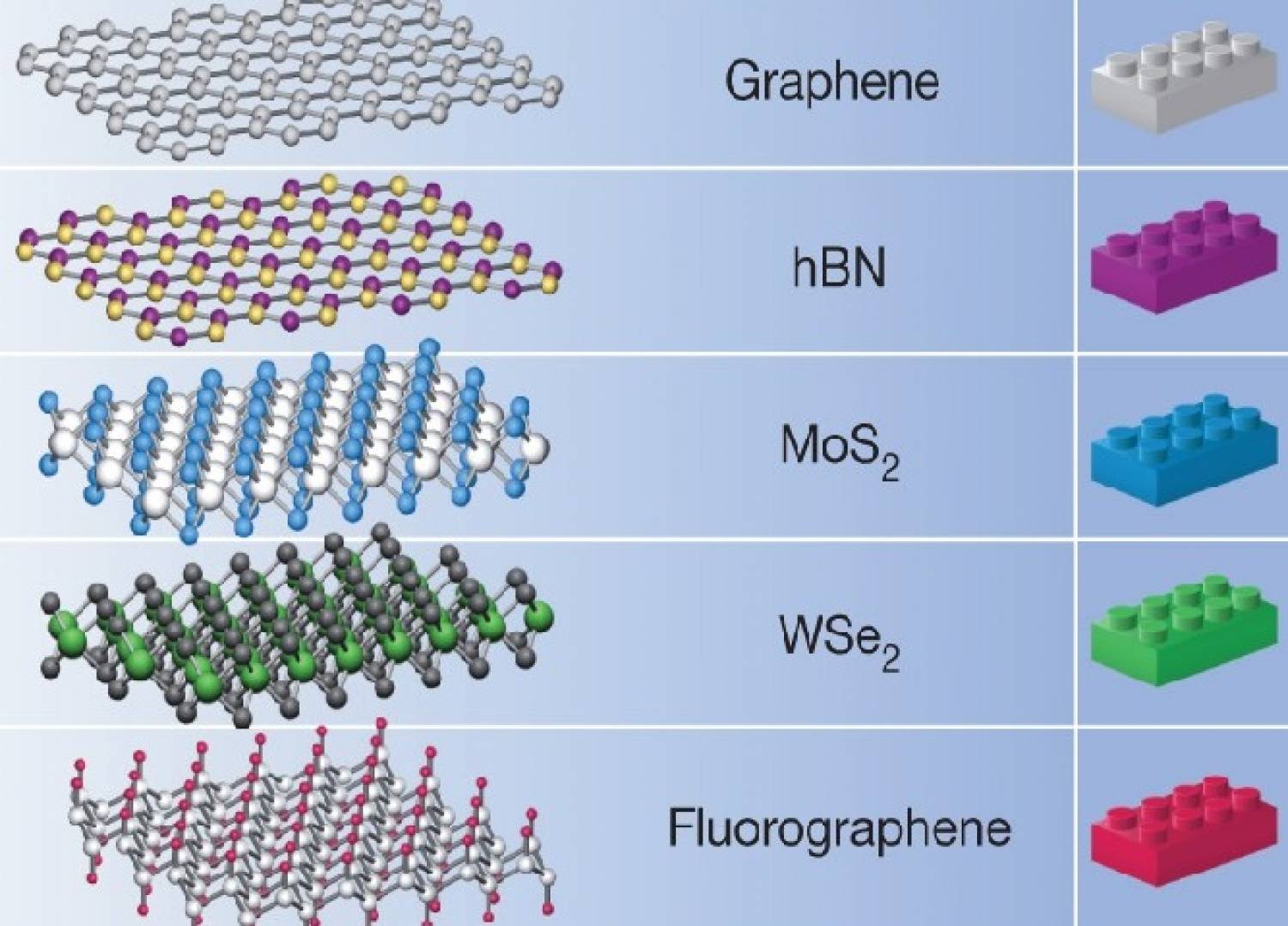

Hexagonal boron nitride (h-BN) possesses a layered crystal structure similar to graphite, contributing to its moniker "white graphite." In this structure, each boron atom is bonded to three nitrogen atoms, forming hexagonal layers. The layers are held together by weak van der Waals forces, allowing them to easily slide over each other. The hexagonal arrangement of boron and nitrogen atoms creates a two-dimensional lattice, resulting in a planar structure.

The distinctive feature of h-BN is its alternating arrangement of boron and nitrogen atoms in hexagonal rings, providing the material with unique properties. This crystal structure imparts excellent electrical insulation, high thermal conductivity, and chemical stability to hexagonal boron nitride, making it a valuable material in various industrial applications. Additionally, the layered structure influences its lubricating properties and contributes to its resemblance to graphite, despite having different properties.

Read more: Hexagonal Boron Nitride vs. Graphene, Hexagonal Boron Nitride VS. Cubic Boron Nitride

Hexagonal Boron Nitride Specification

| Physical Properties | |

| Chemical Formula | BN |

| Density (g/cm3) | 2.28 |

| Color | white |

| Crystal Structure | hexagonal |

| Water Absorption % @R.T. | 0.0-1.0 |

| Hardness Mohs | 2 |

| Mechanical Properties | |

| Compressive Strength MPa @ R.T. | 23.5 |

| Tensile Strength MPa @ R.T. | 2.41(1000ºC) |

| Modulus of Elasticity (Young's Mod.) Gpa | 675 |

| Flexural Strength (MOR) MPa @ R.T. | 51.8 |

| Electrical Properties | |

| Dielectric Constant 1MHz @ R.T. | 4.08 |

| Dielectric Strength kV/mm | 374 |

| Electrical Resistivity Wcm @ R.T. | 10^13 |

| Thermal Properties | |

| Max. Use Temperature (* denotes inert atm.) ºC | 985 |

| Thermal Shock Resistance DT (ºC) | >1500 |

| Thermal Conductivity W/m-K @ R.T. | 20 |

Hexagonal Boron Nitride Applications

Hexagonal boron nitride (h-BN), also known as "white graphite," is a material with diverse applications, thanks to its unique properties. Here's a breakdown of its versatile use across different industries:

Plasma Arc Welding:

- Acts as a protective coating in welding applications.

- High thermal stability prevents molten metal adhesion.

Semiconductor Manufacturing:

- Serves as a substrate for crystal growth equipment.

- High purity and thermal conductivity ideal for semiconductor processing.

Read more: Hexagonal Boron Nitride Used as A Substrate for 2D Materials

Powder Metal Processing:

- Functions as a solid lubricant to reduce friction and wear.

- Enhances the efficiency of powder metallurgy component production.

Aluminum Metal Processing:

- Acts as a mold release agent with thermal stability.

- Non-reactive with molten aluminum, ensuring efficient processing.

Tool and Die Manufacturing:

- Used as a coating material for cutting tools.

- Provides hardness, wear resistance, and thermal stability for prolonged tool life.

ACM Ceramic Product Video

Your HBN Ceramics Supplier

Advanced Ceramic Materials is a leading supplier of hexagonal boron nitride ceramic products of the highest quality for a wide range of applications. We are happy to provide advice on materials, design, and application. Feel free to contact us with any questions about HBN or other ceramic materials that are not listed on the website.

| Chemical Formula | BN |

| Mechanical | |

| Density | 1.9 g/cm3 |

| Hardness | 2.26 GPa |

| Modulus of Elasticity | 46.9 GPa |

| Flexural Strength | 75.8 MPa |

| Compressive Strength | 143 MPa |

| Poisson's Ratio | - |

| Fracture Toughness | - MPa m½ |

| Electrical | |

| Dielectric Strength | 95 ac V/mm |

| Dielectric Constant | 4.6 (@ 1 MHz) |

| Volume Resistivity | 10^14 ohm-cm |

| Thermal | |

| Coefficient of Thermal Expansion | 7.54 x 10^-6/°C |

| Thermal Conductivity | 20 W/(m*K) |

| Specific Heat | 16.1 x10^3 J/(Kg*K) |

| Shock Resistance | - |

| Maximum Working Temperature | 2200 vacuum °C |