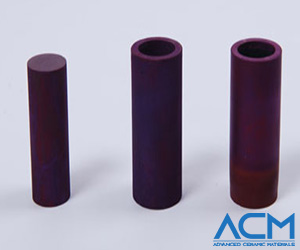

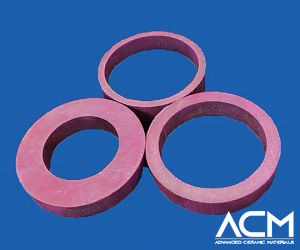

CE1860 Cerium Hexaboride Tube, CeB6 Tube

- Catalog No. CE1860

- Size Min OD 0.2”/Min ID 0.1” Customized

- Density 4.80-4.87 g/cm3

- Appearance Purple

- Melting Point 2552°C

CE1860 Cerium Hexaboride Tube, CeB6 Tube

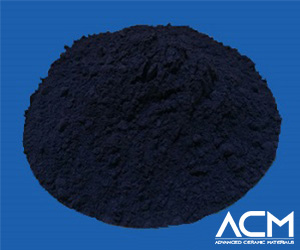

Cerium Hexaboride Tube Description

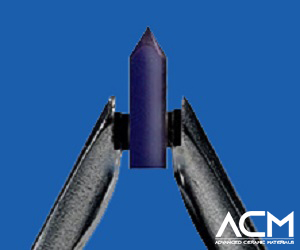

Cerium Boride, also called Cerium Hexaboride or CeB6, is a refractory ceramic material. The principal use of cerium hexaboride is a coating of hot cathodes or hot cathodes made of cerium hexaboride crystals. It usually operates at a temperature of 1450 °C.

Cerium hexaboride, like lanthanum hexaboride, slowly evaporates during the cathode operation. In conditions where CeB6 cathodes are operated under 1850 K, CeB6 should maintain its optimum shape longer and therefore last longer. While the process is about 30% slower than with lanthanum boride, the cerium boride deposits are reported to be more difficult to remove.

Cerium Hexaboride Tube Applications

-Thermionic emission (cathode)

-Plasma source for plasma-enhanced coating(PECVD)

-Vacuum electron beam welding machine

-Electron beam surface reforming device

-Electron beam lithography device

-Transmission electron microscope

-Scanning electron microscope

-Surface analysis device

-Radiotherapy devices

Material Data for LaB6 and CeB6

|

Parameter

|

Units | LaB6 | CeB6 |

|---|---|---|---|

| Stoichiometry |

N/A

|

~6

|

|

| Metal Impurities |

ppm by wt.

|

<30

|

|

| Density |

g/cm3

|

4.72

|

4.80

|

| Coefficient of Thermal Expansion |

α x 106

|

5.6

|

6.2

|

| Electrical Resistivity |

?Ω-cm

|

~50

|

~65

|

| Effective Work Function (100) at 1800 K |

eV

|

2.70

|

2.65

|

| Spectral Emissivity at 0.65 microns |

N/A

|

0.765

|

0.779

|

| Evaporation rate at 1800 K (UHV) |

g/cm2/s

|

2.2 x 10-9

|

1.6 x 10-9

|

| Orientation limit for specific orientation |

degrees

|

<2

|

|

| Pyrolitic block mount resistance @ 1800 K |

Ohms

|

1.45

|

|

Packing Service

ACM’s Cerium Hexaboride Tube is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

-

Attachment (Optional)

No file chosen