Zirconia Powders, ZrO2

ACM’s Zirconia Powder is a premium product in our Zirconium Oxide (Zirconia) series, known for its exceptional purity and consistent quality. Our high-purity zirconia powders are ideal for advanced ceramic applications requiring superior performance.

We also offer a wide range of colors—including white, blue, black, yellow, green, purple, pink, and more—with hues customizable to meet specific customer requirements.

Key Properties of ACM Zirconia Powder:

-

High melting and boiling points for excellent thermal stability

-

Outstanding hardness and strength ensuring durability

-

Good thermal and electrical conductivity suitable for diverse applications

-

Excellent chemical and corrosion resistance for long-term reliability

Zirconia is a highly versatile, advanced ceramic material known for its outstanding thermal stability, mechanical strength, chemical resistance, and electrical insulation. At Advanced Ceramic Materials (ACM), we offer a broad range of zirconia powders tailored for diverse ceramic forming techniques and industrial applications.

Whether you're looking for high-purity zirconia powder for electronic components, yttria-stabilized zirconia (YSZ) for structural ceramics, or colored zirconia powders for decorative and specialized applications, this page gives you the full overview.

Types of Zirconia Powder We Offer

1. Monoclinic Zirconia Powder (m-ZrO2)

-

Crystal Phase: Monoclinic (stable at room temperature)

-

Purity: 99.5% – 99.9%

-

Form: Fine powder

-

Key Features:

-

Thermodynamically stable at ambient conditions

-

Undergoes phase transition upon heating (~1170°C), may cause volume change

-

-

Applications:

-

Ceramic pigments and opacifiers

-

Thermal and refractory coatings

-

Catalyst carriers

-

Metallurgical additives

-

Monoclinic zirconia is a cost-effective material ideal for applications where phase transformation is not critical or is managed during sintering.

2. Pure Zirconia Powder (Non-Stabilized, High-Purity)

-

Phase: Mixed monoclinic/tetragonal or heat-treated variants

-

Purity: ≥99.9%

-

Form: Fine or spray-dried powder

-

Key Features:

-

No stabilizing dopants (e.g., Y2O3, MgO)

-

High chemical purity

-

Controlled grain growth for dense sintered ceramics

-

-

Applications:

-

Ceramic insulators

-

Transparent optical ceramics

-

Technical ceramics requiring low ionic conductivity

-

This high-purity zirconia powder is engineered for applications where absolute purity and thermal durability matter most. It's distinct from stabilized or doped grades.

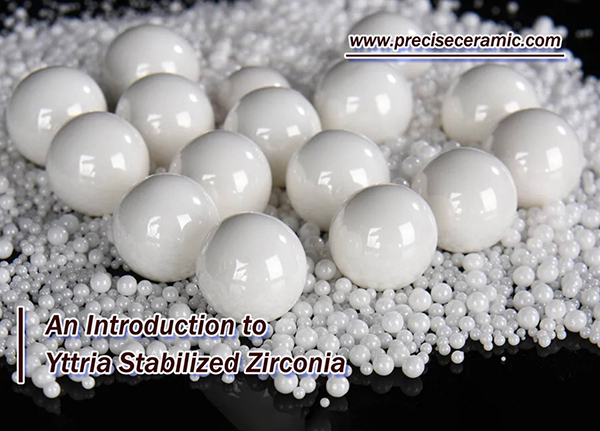

3. Yttria-Stabilized Zirconia (YSZ) Powder

-

Dopant: Y2O3 (typically 3–8 mol%)

-

Crystal Phase: Tetragonal or cubic (phase-stabilized)

-

Form: Fine or spray-dried granules

-

Key Features:

-

Enhanced fracture toughness and thermal shock resistance

-

Stable structure at elevated temperatures

-

-

Applications:

-

Solid oxide fuel cells (SOFC)

-

Dental ceramics

-

Mechanical parts under dynamic load

-

4. Colored Zirconia Powder (Stabilized + Pigment Additives)

-

Color Range: Blue, pink, yellow, black, green, violet, and more

-

Base: Typically YSZ

-

Working Temperatures: 1350°C – 1460°C depending on color

-

Applications:

-

Decorative ceramics

-

Dental frameworks

-

Functional ceramic components with aesthetic requirements

-

Our colored zirconia powders combine stable colorants with high-performance YSZ to ensure color integrity through sintering.

| Color | Code | Working Temperature |

| Blue | CYSZ-B1 | 1400℃ |

| Purplish Blue | CYSZ-B2 | 1400℃ |

| Sky Blue | CYSZ-B3 | 1400℃ |

| Cobalt Blue | CYSZ-B4 | 1400℃ |

| Black | CYSZ-B5 | 1350℃ |

| Cobalt Black | CYSZ-B6 | 1350℃ |

| Dark Green | CYSZ-G1 | 1380℃ |

| Grass Green | CYSZ-G2 | 1400℃ |

| Yellow | CYSZ-Y1 | 1450℃ |

| Golden Yellow | CYSZ-Y2 | 1450℃ |

| Pink | CYSZ-P1 | 1460℃ |

| Violet | CYSZ-V1 | 1400℃ |

| Dark Violet | CYSZ-V2 | 1400℃ |

| Ashen | CYSZ-A1 | 1350℃ |

Form Options & Processing Compatibility

We provide zirconia powders in two primary forms to meet your production needs:

| Form | Suitable For |

|---|---|

| Granular Powder | Dry pressing, isostatic pressing, uniaxial compaction |

| Spray-Dried Powder | Injection molding, slip casting, tape casting, additive manufacturing (3D) |

Particle size, specific surface area, and flowability can be customized upon request.

Applications of Zirconia Powder

Zirconia’s unique properties make it suitable for applications across industries:

-

Structural Ceramics: Cutting tools, pump seals, valve seats

-

Dental Materials: Crowns, bridges, orthodontic frameworks

-

Solid Oxide Fuel Cells (SOFC): Electrolyte membranes

-

Thermal Barrier Coatings: Aerospace and turbine components

-

Decorative Ceramics & Jewelry: Colored zirconia for aesthetic precision

-

Electronic Substrates: High-dielectric ceramics and insulation layers

Packaging & Storage

Zirconia powder is moisture-sensitive (deliquescent) and is therefore:

-

Vacuum-packed in airtight aluminum foil bags or iron drums

-

Shipped in sealed cartons with moisture-proof protection

-

Labeled with product code, batch number, and handling precautions

We recommend storing in a dry, cool, sealed environment away from direct humidity.

Why Choose ACM's Zirconia Powders?

Wide selection: from technical-grade to high-purity zirconia powder

Full customization: color, PSD, form, dopant level

Strict quality control & batch traceability

Global shipping and technical support

Get a Quote or Sample

Looking for bulk orders, R&D samples, or custom solutions?

[Contact us now] for your zirconia powder needs.

| Parameter | Value / Unit |

|---|---|

| Chemical Formula | ZrO2 |

| Density | ~6 g/cm³ |

| Hardness | ~13 GPa |

| Modulus of Elasticity | ~220 GPa |

| Fracture Toughness | ~4 MPa·m½ |

| Coefficient of Thermal Expansion | ~9.5 x 10^-6 /°C |

| Shock Resistance | ~300 °C Difference |

| Maximum Working Temperature | ~1000 °C |