BN0948 Boron Nitride Plate, BN Plate

- Catalog No. BN0948

- Chemical Formula BN

- Molecular Weight 24.82

- Appearance 2973 °C

- Density 2.1 g/cm3 (h-BN); 3.45 g/cm3 (c-BN)

- Solubility in Water Insoluble

- Refractive Index 1.8 (h-BN); 2.1 (c-BN)

- Electrical Resistivity 13 to 15 10x Ω-m

Datasheet

Inquiry

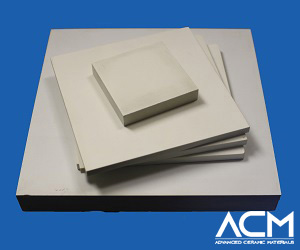

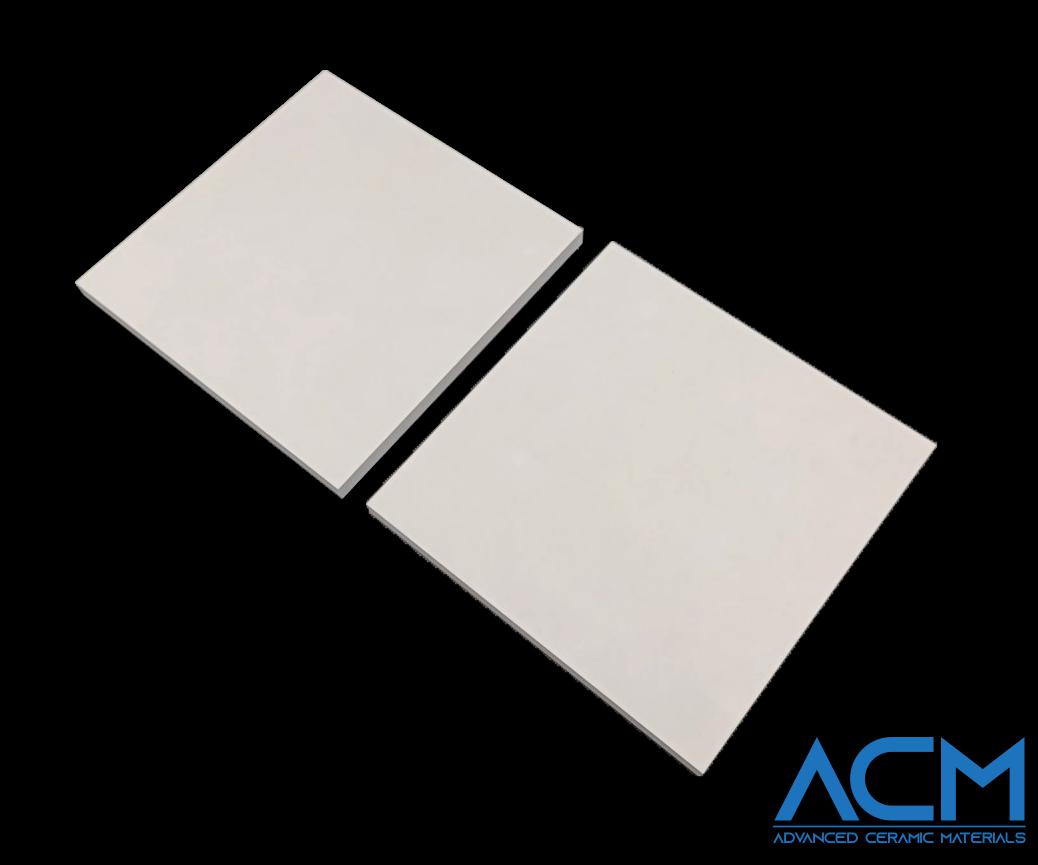

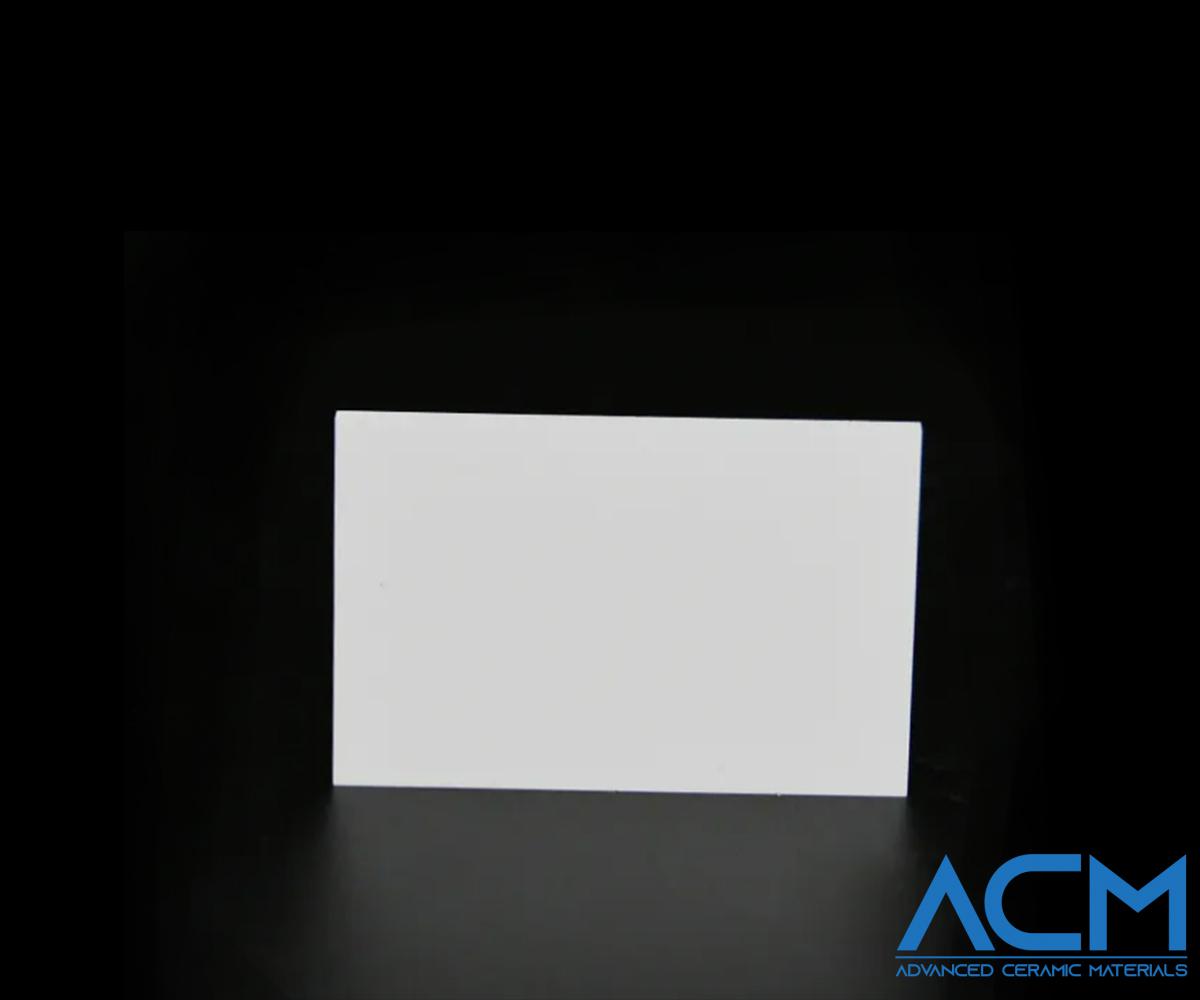

BN0948 Boron Nitride Plate, BN Plate

Boron Nitride Plate Description

Similar to graphite, boron nitride ceramic has great strength at high temperatures. High-purity PBN products have even better mechanical properties. As the solid material is formed by the CVD process, the density of the products could almost reach the theoretical value. PBN products provided by Advanced Ceramic Materials also have great thermal shock resistance. Plates of PBN could be heated to more than 2000 degrees and dropped into the water without getting broken.

Boron Nitride Plate Specifications

|

Item |

value |

Unit |

|

|

lattice constant |

a:2.504×10-10???? c:6.692×10-10 |

μ m |

|

|

density |

2.0-2.19 |

g/cm3 |

|

|

resistivity |

3.11×1011 |

Ω·cm |

|

|

tensile strength(ab) |

153.86 |

N/mm2 |

|

|

bend strength |

c |

243.63 |

N/mm2 |

|

ab |

197.76 |

N/mm2 |

|

|

elastic modulus |

235690 |

N/mm2 |

|

|

thermal conductivity |

“a” direction “c” direction |

||

|

(200℃) |

60 2.60 |

W/m·k |

|

|

(900℃) |

43.70 2.80 |

W/m·k |

|

|

dielectric strength(at room temperature) |

56 |

KV/mm |

|

Please notice, as a CVD material, pyrolytic boron nitride sheets could not be very thick. The largest thickness available for our PBN sheet is 0.2". We also provide PBN crucibles, tubes, and heating elements!

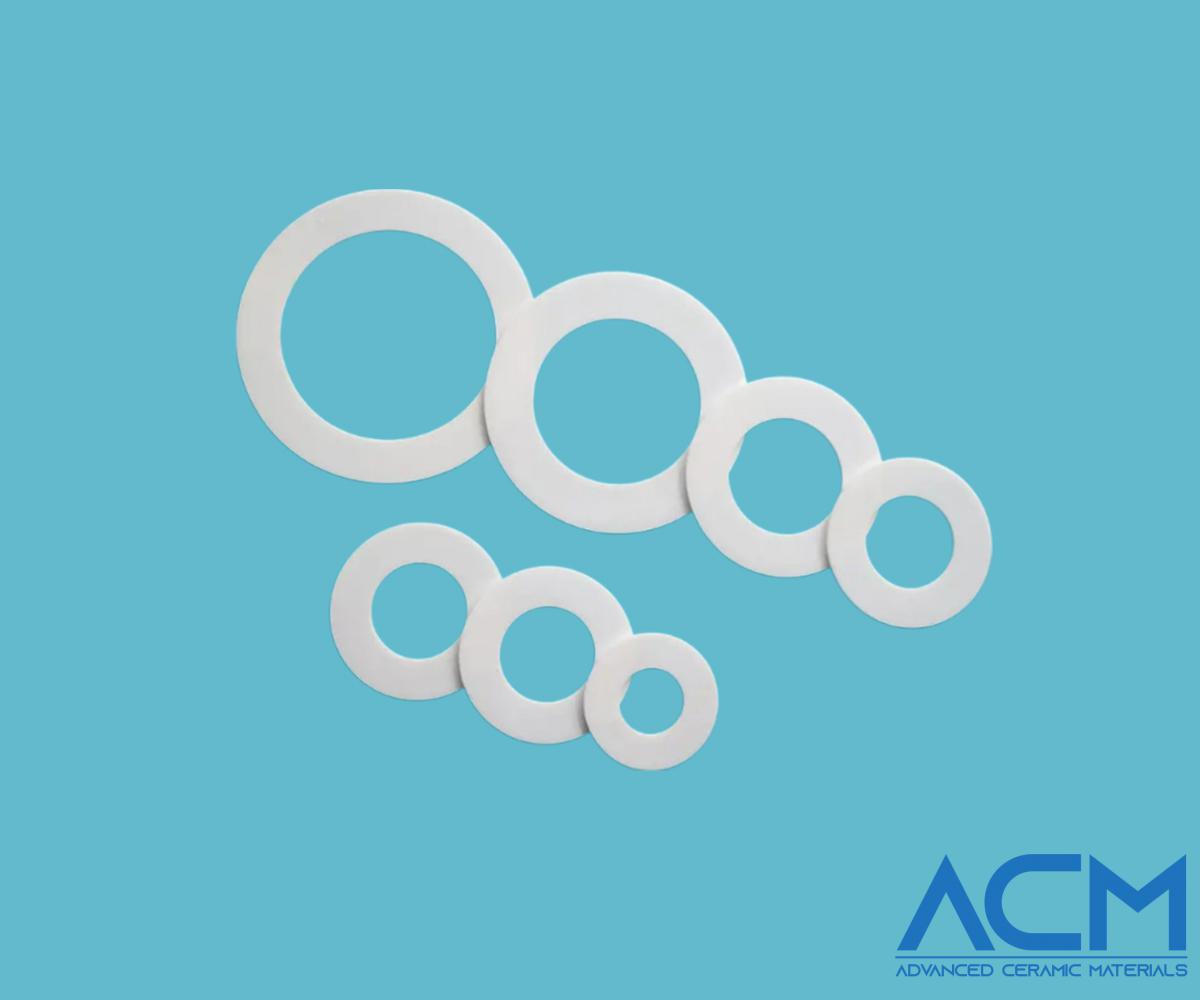

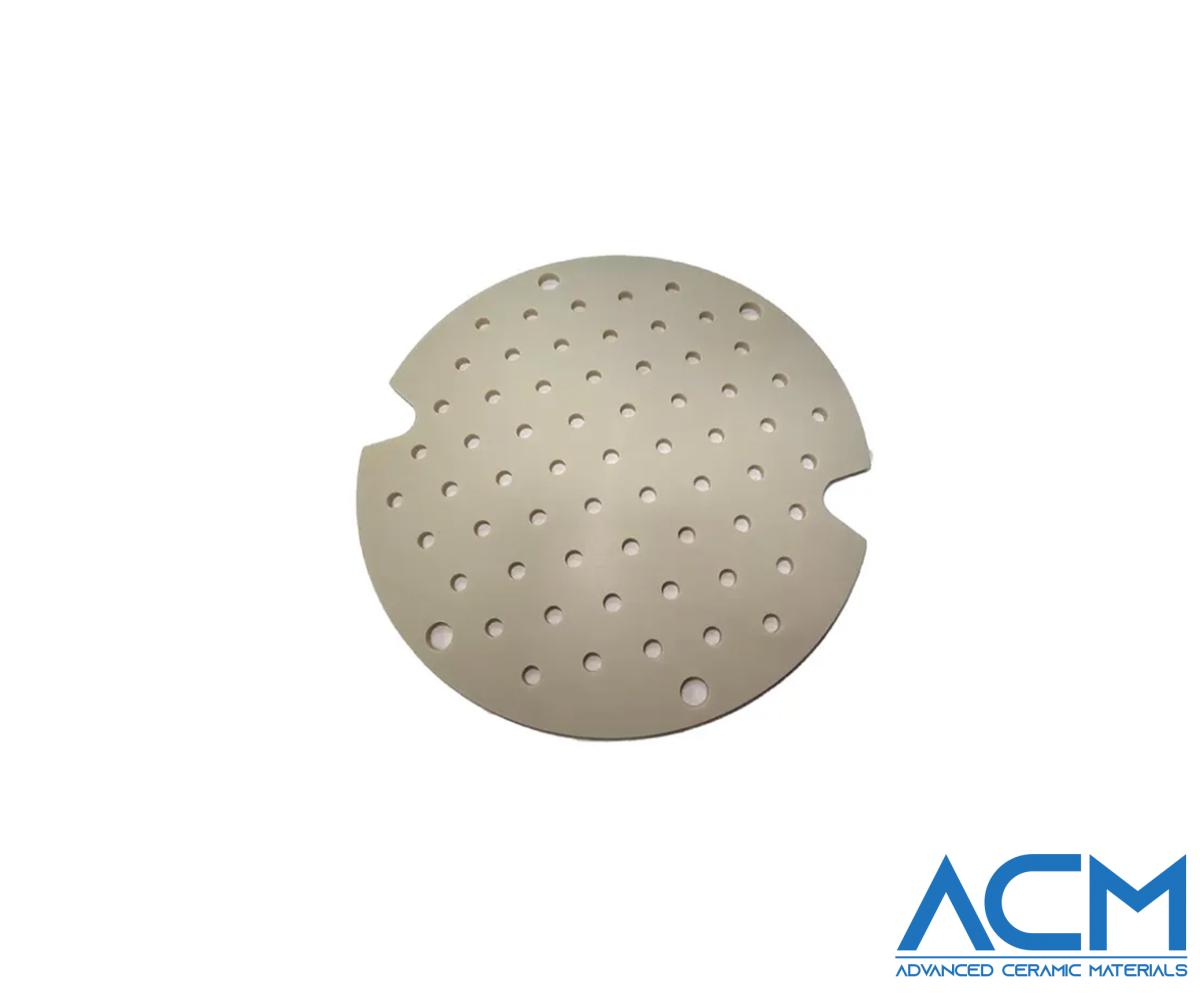

Boron Nitride Plate / Disc Applications

Boron Nitride ceramic from Advanced Ceramic Materials can withstand high temperatures in a high vacuum environment, plus it has excellent corrosion resistance and electrical resistance. Thus, Boron Nitride ceramic product is an ideal choice in a wide range of industries, such as:

-Electric insulators in the vacuum system

-Boron Nitride components for PVD, MOCVD, MBE systems.

-Nozzles for the nonferrous metals metallurgy industry

-Spacers for glass melting

-Insulators for high-temperature furnace

Packing Service

ACM’s High Purity Boron Nitride Plates/Discs are carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Request a Quote

-

Attachment (Optional)

No file chosen