BN0948 Hot Pressed Boron Nitride Plate, BN Plate

- Catalog No. BN0948

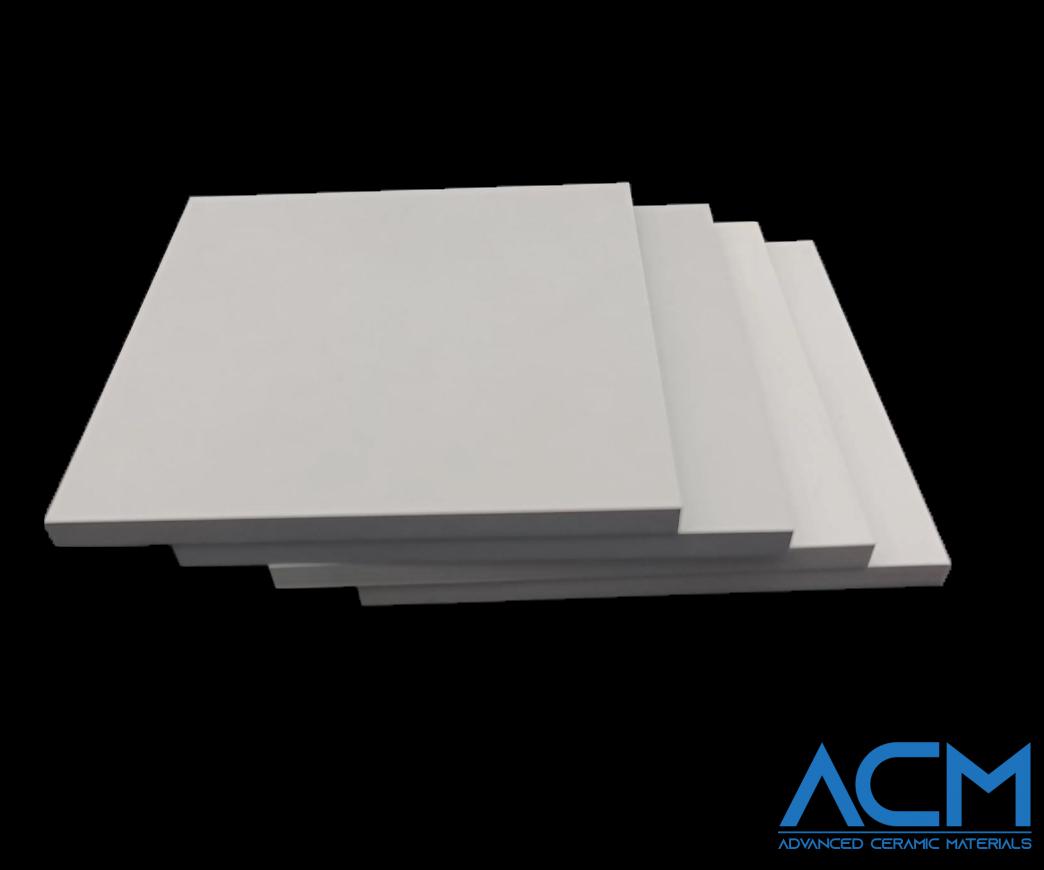

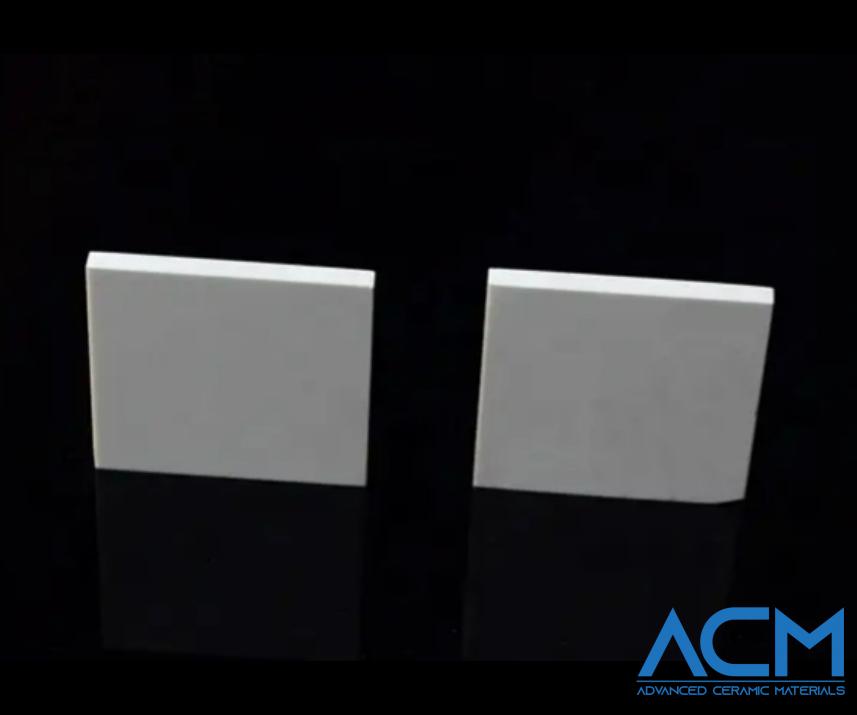

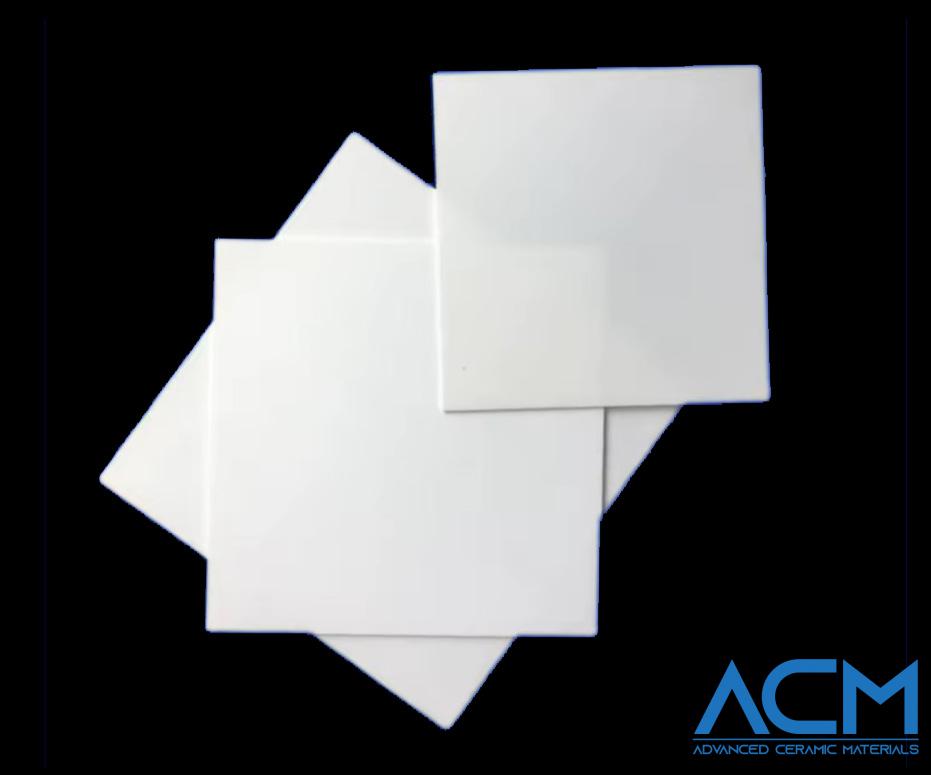

- Appearance White

- Melting Point 2973 °C

- Density 2.1 g/cm3 (h-BN); 3.45 g/cm3 (c-BN)

- Refractive Index 1.8 (h-BN); 2.1 (c-BN)

- Electrical Resistivity 13 to 15 10x Ω-m

Datasheet

Inquiry

BN0948 Hot Pressed Boron Nitride Plate, BN Plate

Hot Pressed Boron Nitride Plate Description

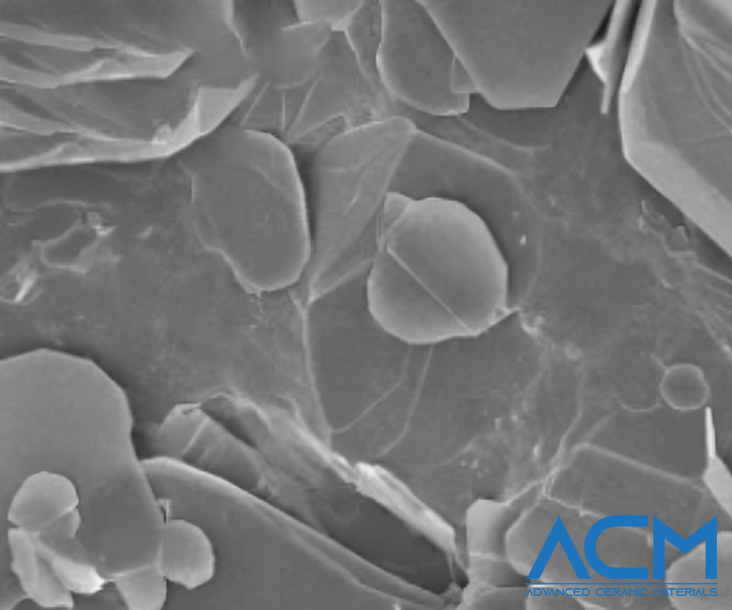

Boron nitride plate is composed of boron nitride, or BN, which is a chemical compound with equal numbers of boron and nitrogen atoms. The hexagonal boron nitride (HBN) corresponding to "white graphite" is the softest and most stable form among BN polymorphs, and is therefore used as a lubricant and an additive to cosmetic products. The cubic (CBN) variety, analogous to diamon,d has a high hardness which is inferior only to diamond. The rare wurtzite BN (WBN) modification is similar to lonsdaleite, and it may even be harder than CBN.

Boron Nitride Plate: Available Materials

| Grade | BN99 (Grade AX05) |

BN-BO (Grade A) |

BNCB (Grade HP) |

BNSIO (M&M26) |

BN-AlN | ZSBN |

| Composition | hBN > 99.5% | hBN > 98% | hBN > 90% Calcium Borate |

hBN 40%, SiO2 60% (M) hBN 60%, SiO2 40% (M26) |

BN+AlN AlBO3 |

hBN > 45% ZrO2 < 45% Borosilicate < 10% |

| Color | white | white | white | white | white | gray |

| Density (g/cm3) |

1.9 | 2.1 | 2 | 2.1-2.3 | 2.5-2.6 | 2.9 |

| Features | • Excellent corrosion resistance • High thermal conductivity • Thermal shock resistance |

• Excellent moisture resistance • Low thermal expansion • Spallation resistance |

• Thermal shock resistance • High thermal conductivity • Moisture resistance |

• High thermal conductivity • High-temperature resistance • Easy machining |

• Good wear resistance • Chemical stability • High thermal shock stability |

|

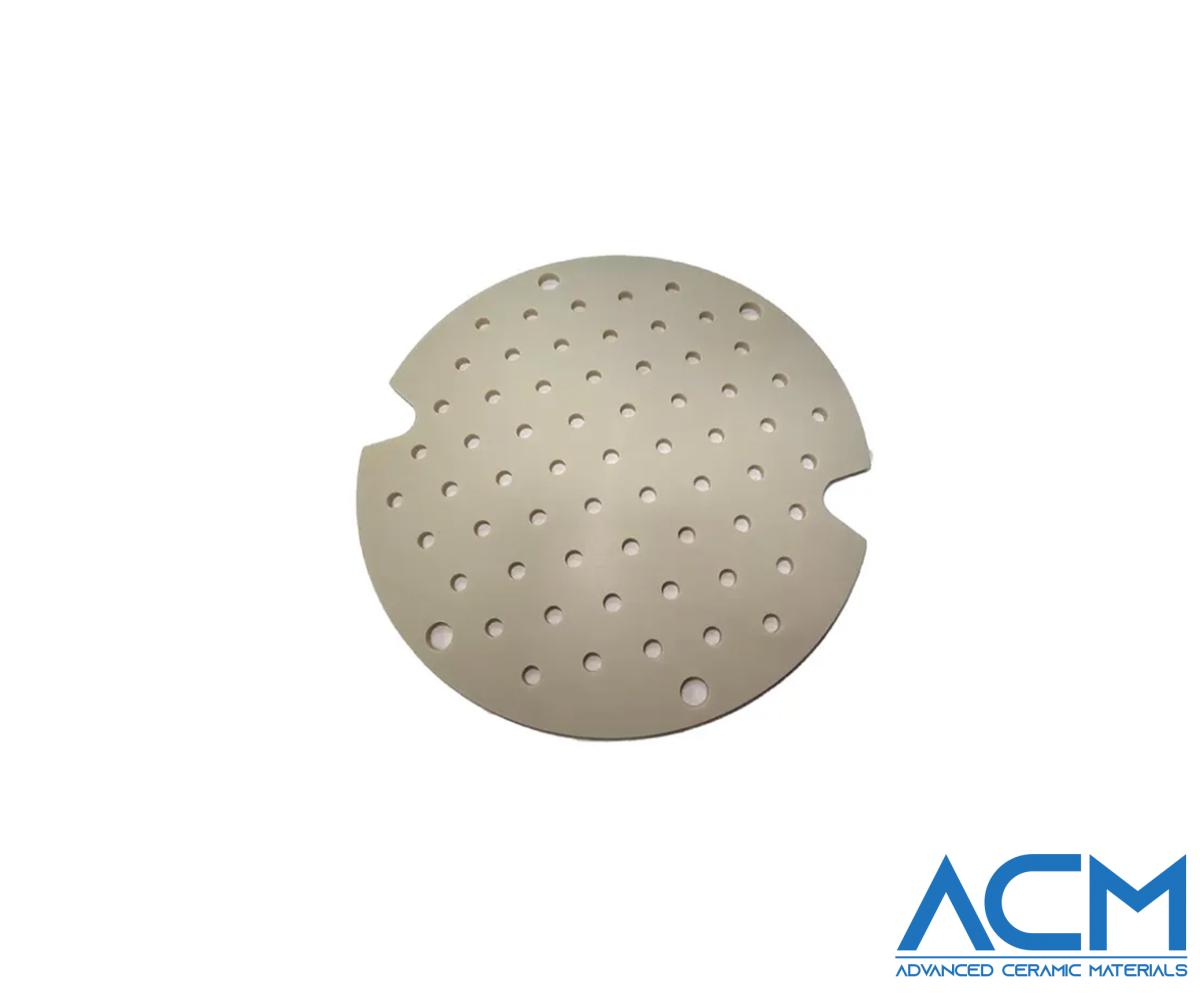

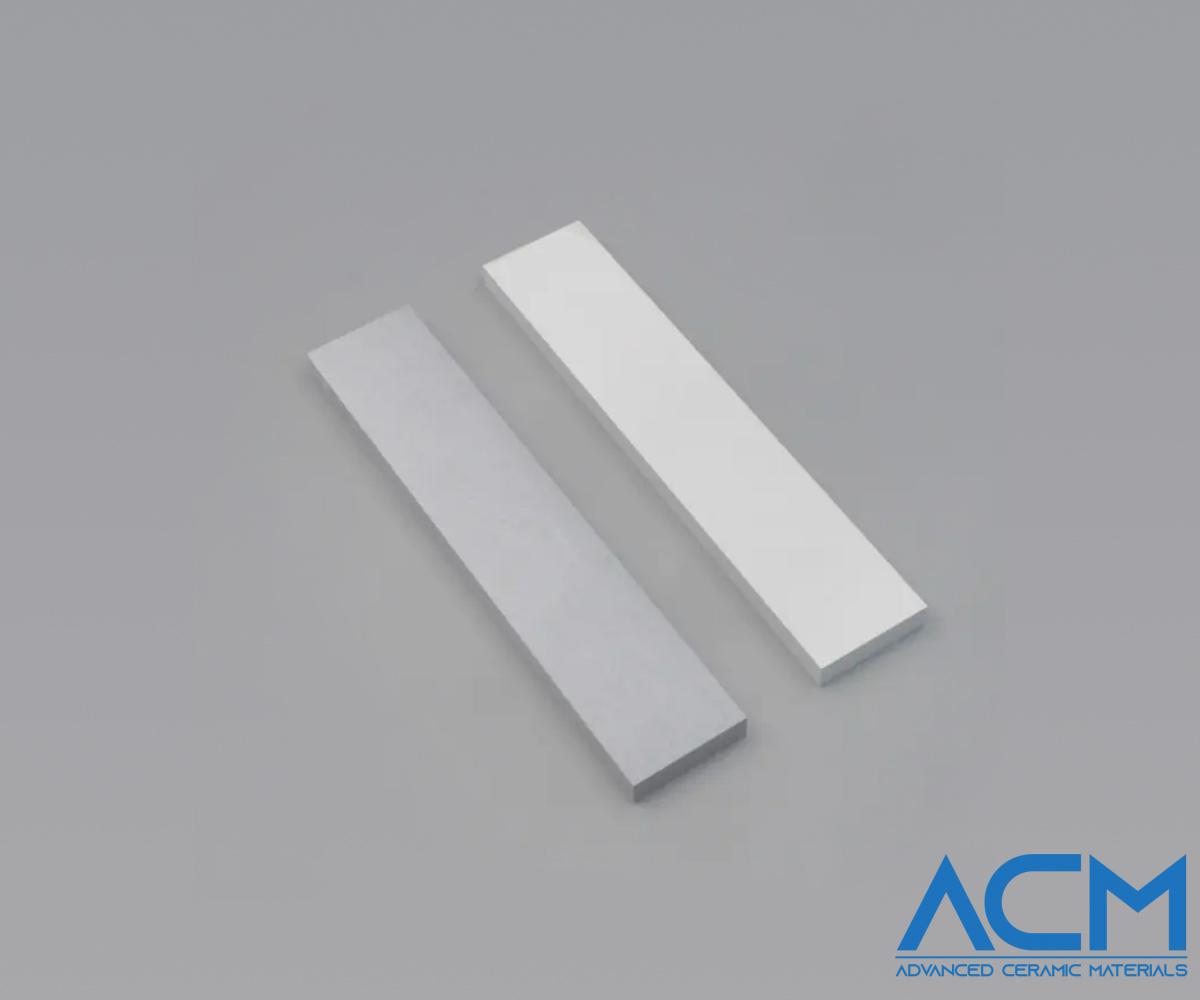

| Shape | Rod Plate/Sheet Tube Crucible Custom part |

Rod Custom part |

Custom part | Custom part | Custom part | Nozzle Custom part |

| Size | Customized | Up to 410mm x 495mm x 245mm | Up to 410mm x 495mm x 245mm | Customized | Customized | Customized |

* For customized information, please contact us.

Hot Pressed Boron Nitride Plate Advantages

- Low Wettability to Molten Metals: Ensures superior performance in metal processing environments.

- Low Dielectric Constant: Makes it an ideal insulator in electrical applications.

- High Dielectric Strength: Provides robust electrical resistance.

- High Thermal Conductivity with Low Thermal Expansion: Enables excellent heat dissipation with minimal expansion under temperature changes.

- High Thermal Shock Resistance: Allows the material to withstand sudden temperature changes.

- Extremely High Working Temperature: Capable of operating at temperatures exceeding 3000°C with appropriate inert gas protection.

- Chemical Vapor Deposition (CVD) Compatibility: Suitable for advanced manufacturing processes.

Hot Pressed Boron Nitride Plate Applications

Boron Nitride ceramic plates from Advanced Ceramic Materials (ACM) are designed to perform exceptionally well under extreme conditions. They can withstand high temperatures in vacuum environments and offer excellent corrosion and electrical resistance due to their chemically inert nature. These unique properties make Boron Nitride plates an ideal choice across various industries, including:

- Electric Insulators in Vacuum Systems: Provide reliable electrical insulation in high-vacuum applications.

- Insulators for High-Temperature Furnaces: Maintain electrical insulation and structural integrity at elevated temperatures.

- Spacers for Glass Melting: Serve as durable spacers that can withstand the intense thermal environment of glass melting processes.

- Components for Ion Injection Equipment: Ensure stability and durability in ion implantation and other high-energy processes.

Packing Service

ACM’s boron nitride ceramic plates (BN plates) are carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition. Boron nitride plate can be easily machined, please contact us for more information about boron nitride machining.

Frequently Asked Questions (FAQ)

Q1: What are the key benefits of using Boron Nitride plates ?

Boron Nitride plates offer excellent thermal stability, high electrical insulation, low thermal expansion, and outstanding chemical inertness. They can withstand high temperatures in vacuum environments and provide reliable performance in corrosive or high-energy settings.

Q2: Are Boron Nitride plates suitable for electrical insulation?

Yes, Boron Nitride plates are highly suitable for electrical insulation, especially in high-temperature and vacuum environments. Their low dielectric constant and high dielectric strength make them ideal for use in various electronic and electrical applications.

Q3: Can Boron Nitride plates be customized for different applications?

Yes, Boron Nitride plates can be customized in terms of size, thickness, and shape to meet specific application requirements. ACM offers a range of customization options to ensure the best fit for your needs.

Q4: How resistant are Boron Nitride plates to thermal shock?

Boron Nitride plates have excellent thermal shock resistance, which allows them to endure rapid temperature changes without cracking or degrading, making them ideal for high-temperature applications.

Q5: What are common applications for Boron Nitride plates?

Common applications include use as insulators in high-temperature furnaces, spacers in glass melting processes, components in ion implantation equipment, and electrical insulators in vacuum systems.

Q6: How should Boron Nitride plates be stored to maintain their quality?

To preserve their quality, Boron Nitride plates should be stored in a clean, dry environment, away from moisture and mechanical stress.

Request a Quote

-

Attachment (Optional)

No file chosen