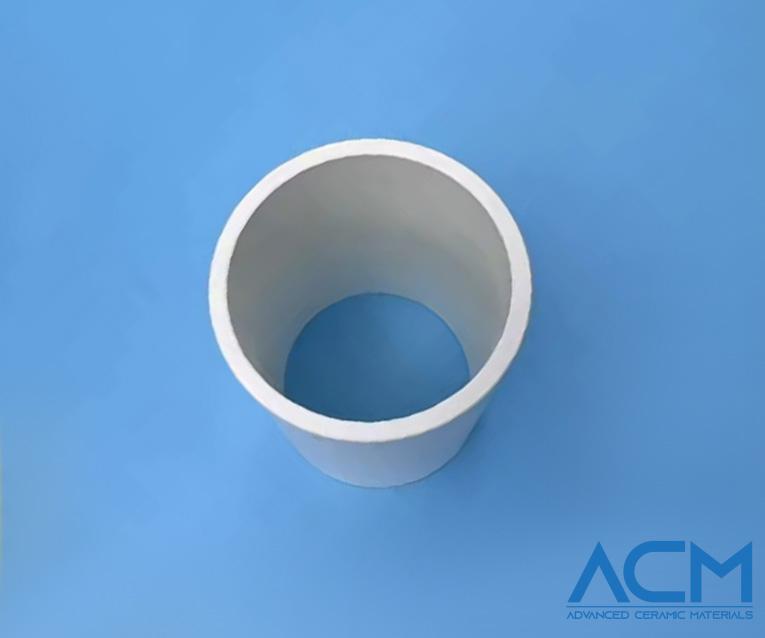

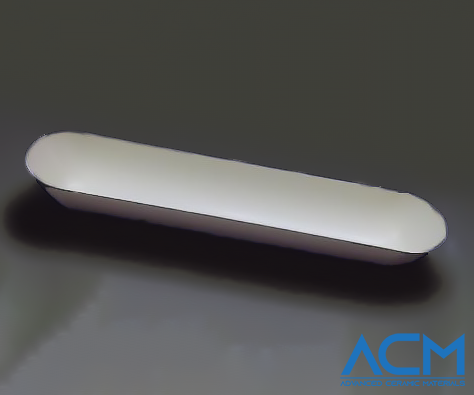

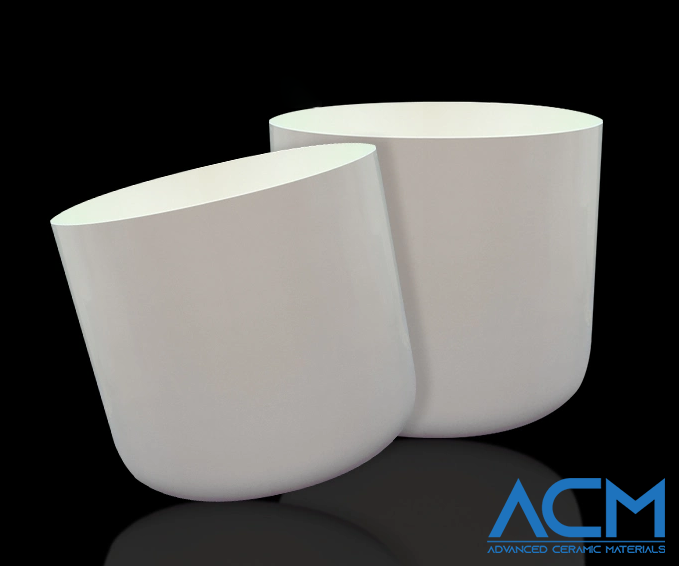

PBN0923 PBN Tube, Pyrolytic Boron Nitride Tube

- Catalog No. PBN0923

- Material PBN

- Purity 99.99%

- Density 2.0-2.19 g/cm3

- Wall Thickness <2mm

Datasheet

Inquiry

PBN0923 PBN Tube, Pyrolytic Boron Nitride Tube

PBN Tube Description

Pyrolytic Boron Nitride (PBN) Tubes offer exceptional purity and are a superior choice compared to standard boron nitride ceramics. These tubes, along with other pyrolytic boron nitride products, are synthesized through the chemical vapor deposition (CVD) process, where BCl₃ and NH₃ are reacted at high temperatures and low pressures to create an ultra-pure material. Due to the controlled nature of the vapor phase, PBN products achieve purity levels exceeding 99.99%, with total impurities less than 100 ppm. This extreme purity makes PBN tubes ideal for applications in the semiconductor industry.

Like graphite, boron nitride demonstrates excellent strength at high temperatures, but PBN tubes offer even better mechanical properties. Formed through the CVD process, these tubes have densities that nearly reach theoretical values. PBN products, including tubes provided by Advanced Ceramic Materials, also exhibit remarkable thermal shock resistance—able to withstand temperatures exceeding 2000 degrees Celsius and rapid cooling without breaking.

PBN Tube Specification

|

Material |

PBN |

|

Bulk Density |

2.0-2.19g/cm3 |

|

Wall thickness |

<2mm |

|

Max. Working Temperature |

2400℃ |

|

Volume Resistivity (Ω·cm) |

3.11*1011 |

|

Thermal Conductivity (W/M·k) |

43-60 |

|

Tensile Strength (N/mm2) |

153.86 (parallel) |

|

Bending Strength (N/mm2) |

243.63 (parallel) |

|

Dielectric Strength (RT) (KV/mm) |

56 |

PBN Tube Applications

Pyrolytic Boron Nitride (PBN) tubes are highly valued for their high purity, thermal stability, and chemical resistance, making them ideal for several critical applications:

-

Crystal Growth in Semiconductor Manufacturing: PBN tubes are used as containers or liners within crucibles in MOCVD systems, crucial for growing high-purity semiconductor crystals like GaN and SiC.

-

High-Temperature Furnace Linings: They serve as protective linings in high-temperature furnaces, ensuring material purity during processes like annealing.

-

Thermocouple Protection: PBN tubes protect thermocouples in corrosive environments, ensuring accurate temperature measurement and extended lifespan.

-

Microwave Plasma Reactors: PBN tubes act as insulators and plasma containment vessels, essential in the production of high-purity materials.

Packing Service

ACM’s PBN Tubes are carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Request a Quote

-

Attachment (Optional)

No file chosen