Ceramic Materials Used as Substrates

Introduction

Ceramic materials have a wide range of applications due to their unique properties, including high strength, durability, and resistance to high temperatures and corrosion. One common use of ceramics is as substrates, which are the base materials onto which other materials or components are attached. In this article, we will explore some ceramic substrate materials.

What Are Ceramic Substrates?

Ceramic substrates are a type of advanced ceramic material used to provide a stable base for components in automotive, electronic, and industrial applications. The substrate typically has a flat, rectangular shape, with a smooth and uniform surface. It is made of a ceramic material such as alumina or silicon carbide, which has promising mechanical, thermal, and electrical properties.

--Key Features of Ceramic Substrates

Ceramic substrates are characterized by the following characteristics.

- Impressive Thermal Performance: These materials have a low thermal expansion coefficient and high thermal conductivity, which could increase the efficiency of components and reduce the possibility of heat damage. For instance, the thermal conductivity of SiC is no less than that of metals.

- Remarkable Electrical Features: With higher electrical conductivity, chips and other components based on ceramic substrates use less energy, and the signal delay time can be reduced.

--Main Applications of Ceramic Substrates

Thanks to these desirable properties, ceramic substrates find applications in a variety of industries.

-

The Automotive Industry

You can find a broad range of ceramics employed to make electric power steering, integrated starter alternators, diesel and water pump controls, and motor and engine controls for vehicles. These devices could not only reduce fuel consumption but also decrease exhaust pollution.

- The Renewable Energy Field

These substrates are applied to the renewable energy industry to manufacture inverters for photovoltaics solar and concentrators for concentrator photovoltaics.

Related reading: What Are the Ceramic Substrate Materials Used in Electronic Packaging?

- Other Sectors

Their industrial applications involve pump controls, variable frequency drives, power supplies, and standardized semiconductor modules.

Which Ceramic Materials Could Be Used as Substrates?

Ceramic substrates can be divided into different types according to the raw materials.

--Alumina

Alumina is the most commonly used substrate material for its high strength, good thermal conductivity, and electrical insulation properties. It stands out for its chemical stability and abundance as well. Alumina is often used in electronic applications such as circuit boards, as well as in the production of catalytic converters, high-temperature furnace tubes, and biomedical implants.

Related reading: Uses Of Alumina Substrate In the Automobile Industry

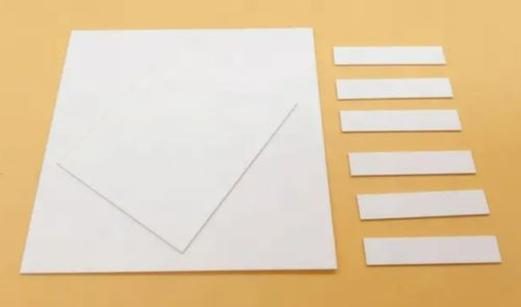

Figure 1. Alumina Substrates

--Zirconia

Zirconia is a ceramic material that is known because it is extremely strong and tough. Such a substrate is extensively employed in dental implants and hip replacements. You can also find it in the production of oxygen sensors and fuel cells.

--Silicon Carbide

Silicon carbide has excellent thermal conductivity and resistance to high temperatures and corrosion. Its high thermal conductivity is 100 w /(m·k) - 400W/(m·k) at high temperatures. Therefore, SiC finds application in high-temperature apparatus such as furnace components, as well as in the production of semiconductor devices.

--Silicon Nitride

Si3N4 has a thermal conductivity of up to 400W/ (m·K), making itself a popular substrate material for high-temperature applications such as gas turbine components, and in the production of bearings and cutting tools.

You can check Table 1 for details of these 4 commonly used ceramic substrate materials.

Table 1. Main Ceramic Materials Used as Substrates

|

|

Key Features |

Main Applications |

|

Alumina (common) |

High strength, Good thermal conductivity, Electrical insulation properties, and chemical stability |

Circuit boards, Catalytic converters, High-temperature furnace tubes, and biomedical implants |

|

Zirconia (strong) |

Strength and toughness |

Dental implants, Hip replacements, The production of oxygen sensors and fuel cells |

|

Silicon Carbide |

Excellent thermal conductivity and resistance to high temperatures and corrosion |

Furnace components, The production of semiconductor devices |

|

High thermal conductivity |

Gas turbine components, The production of bearings and cutting tools. |

--Other Ceramic Materials Used as Substrates

There are many more useful ceramic substrate materials.

- Cordierite: Cordierite is notable ceramic for its low thermal expansion coefficient and good thermal shock resistance. It is often used as a substrate in automotive applications such as catalytic converters, as well as in the production of high-temperature furnace tubes and kiln furniture.

- Mullite: Mullite is utilized as a substrate in high-temperature applications such as furnace components and kiln furniture because of its high strength and good thermal shock resistance.

- Glass-ceramics: Glass-ceramics are produced by controlled crystallization of glasses. They are often used as substrates in electronic applications such as sensors and optical components for their high strength, low thermal expansion coefficient, and good thermal shock resistance.

Conclusion

In a word, there are many ceramic materials that can be utilized as substrates, each with its desirable properties and applications. Alumina, zirconia, silicon carbide, silicon nitride, cordierite, mullite, and glass ceramics are some of the most commonly used ceramic substrates in various industries. Choosing the right ceramic material for a specific application requires careful consideration of its properties and performance requirements. With continued research and development, the potential applications of ceramic substrates are limitless.

Advanced Ceramic Materials (ACM) is a leading supplier of various advanced ceramics, including alumina, beryllia, etc. Hope that you can get suitable ceramic substrates on our website.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments