PBN1343 PBN Sheet, Pyrolytic Boron Nitride Sheet

- Catalog No. PBN1343

- Material Pyrolytic Boron Nitride (PBN)

- Thickness 0.5mm~4mm

- Purity 99.99%

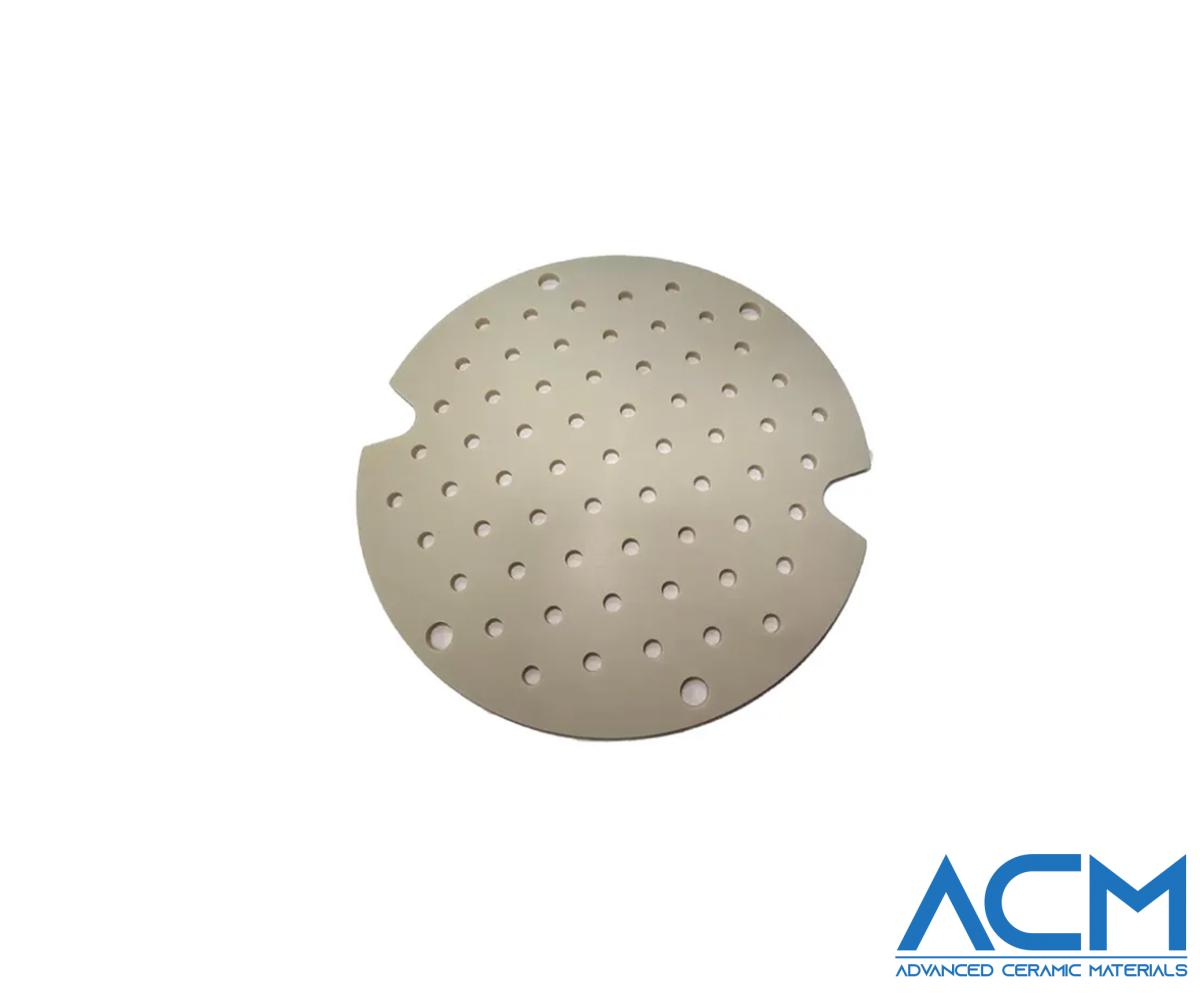

- Shape Sheet

Datasheet

Inquiry

PBN1343 PBN Sheet, Pyrolytic Boron Nitride Sheet

PBN Sheet Description

Pyrolytic Boron Nitride (PBN) Sheets offer significantly higher purity levels compared to standard boron nitride ceramics. These sheets, along with other pyrolytic boron nitride products, are synthesized using the Chemical Vapor Deposition (CVD) process, where BCl₃ and NH₃ react at high temperatures and low pressures to produce ultra-pure materials. The CVD process allows for precise control over vapor purity, resulting in PBN products with total impurities of less than 100 ppm, achieving a purity level of over 99.99%. This exceptional purity makes PBN sheets ideal for critical applications, particularly in the semiconductor industry.

Similar to graphite, boron nitride exhibits excellent strength at high temperatures, but high-purity PBN products offer even better mechanical properties. Formed through the CVD process, PBN sheets achieve densities close to their theoretical maximum, ensuring robust performance. Additionally, PBN sheets provided by Advanced Ceramic Materials have outstanding thermal shock resistance, capable of withstanding temperatures above 2000°C and rapid cooling without damage.

PBN Sheet Specification

|

Item |

value |

Unit |

|

|

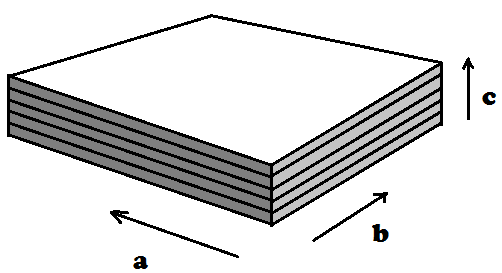

lattice constant |

a:2.504×10-10 c:6.692×10-10 |

μ m |

|

|

density |

2.0-2.19 |

g/cm3 |

|

|

resistivity |

3.11×1011 |

Ω·cm |

|

|

tensile strength(ab) |

153.86 |

N/mm2 |

|

|

bend strength |

c |

243.63 |

N/mm2 |

|

ab |

197.76 |

N/mm2 |

|

|

elastic modulus |

235690 |

N/mm2 |

|

|

thermo conductivity |

“a” direction “c” direction |

||

|

(200℃) |

60 2.60 |

W/m·k |

|

|

(900℃) |

43.70 2.80 |

W/m·k |

|

|

dielectric strength(at room temperature) |

56 |

KV/mm |

|

PBN Sheet Applications

PBN sheets from Advanced Ceramic Materials are known for their exceptional purity, thermal stability, and chemical resistance, making them ideal for:

- Substrates for Semiconductor Manufacturing: Used as a stable, non-reactive base for thin film deposition and epitaxial growth.

- Insulators in High-Temperature Furnaces: Provides reliable insulation in environments requiring high thermal stability.

- Microwave and RF Applications: Acts as a dielectric material in devices that demand high purity and thermal resistance.

- Vacuum Sealing and Gasket Material: Used in high-vacuum systems where contamination control is critical.

- Protective Barriers in Chemical Processing: Serves as a chemically inert barrier in corrosive environments.

Packing Service

ACM’s PBN Sheets are carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Request a Quote

-

Attachment (Optional)

No file chosen