Yttria Stabilized Zirconia, YSZ

Yttria stabilized zirconia (YSZ) is a specialized ceramic material designed to maintain the cubic crystal structure of zirconium dioxide at room temperature, enhancing its physical properties for a variety of applications. The addition of yttrium oxide, or yttria, is a common method for achieving this stabilization, although other oxides like magnesium oxide, calcium oxide, and cerium oxide can also be used for similar purposes. This process shifts zirconia from its natural monoclinic, tetragonal, or cubic phases to a predominantly tetragonal phase, thereby significantly improving its wear resistance and strength.

YSZ, along with its counterparts such as magnesia-stabilized, calcia-stabilized, and ceria-stabilized zirconia, shares a set of desirable properties including high strength, chemical inertness, and exceptional resistance to thermal shock, high temperatures, oxidation, and corrosion, making it an ideal choice for applications demanding durability and reliability under extreme conditions. From aerospace and automotive components to cutting-edge medical implants and high-temperature furnaces, YSZ and its variants play a pivotal role in advancing the capabilities and lifespan of high-performance materials.

More Info About Yttria Stabilized Zirconia

Products | Structures | Specification | Applications | Video | FAQs | Product Brochure

Yttria Stabilized Zirconia Structures

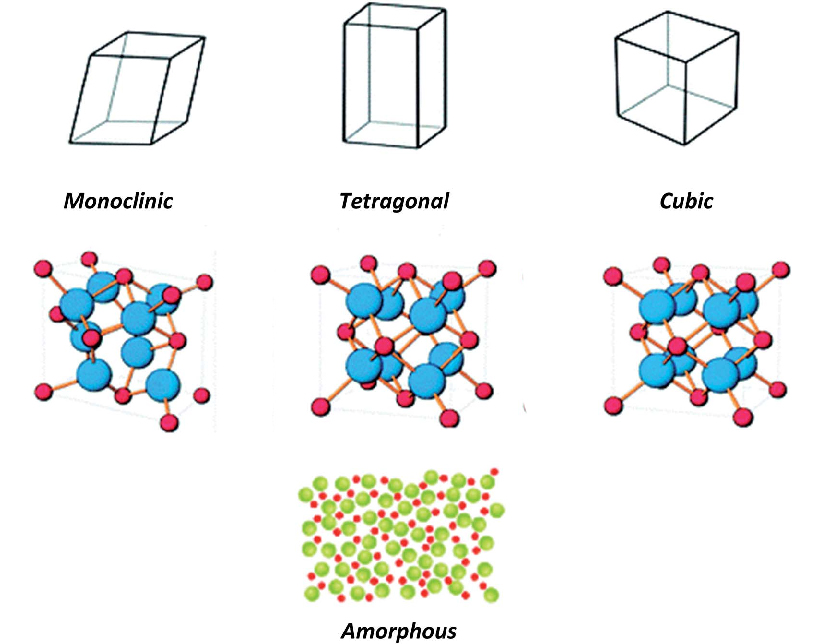

Yttria Stabilized Zirconia (YSZ) exhibits polymorphism, meaning it can exist in multiple crystal structures: monoclinic, tetragonal, and cubic. Each of these structures is stabilized under different conditions, primarily influenced by the yttria (Y2O3) content and temperature.

Asadikiya, Mohammad & Sabarou, Hooman & Chen, Ming & Zhong, Yu. (2016). Phase Diagram for Nano Yttria-Stabilized Zirconia System. RSC Advances. 6. 17438-17445. 10.1039/C5RA24330K.

Monoclinic Phase: In its pure form, zirconia (ZrO2) naturally exists in a monoclinic crystal structure at room temperature. This phase is characterized by a low symmetry and is less dense compared to the tetragonal and cubic phases. The addition of yttria disrupts this phase, stabilizing the zirconia in the tetragonal and cubic phases at lower temperatures. The monoclinic phase is seldom desired in YSZ applications due to its inferior mechanical properties and thermal stability.

Tetragonal Phase: The tetragonal phase of YSZ is stabilized at intermediate yttria concentrations (approximately 3 mol% to 8 mol% Y2O3) and is known for its significant toughness. This is due to the mechanism of transformation toughening, where stress-induced transformation from the tetragonal to monoclinic phase at the crack tip absorbs energy and slows crack propagation. The tetragonal phase is highly valued for applications requiring high strength and toughness.

Cubic Phase: At higher yttria concentrations (above 8 mol% Y2O3), the cubic phase becomes stable at all temperatures up to the melting point of the material. This phase exhibits a high degree of symmetry and is characterized by its high ionic conductivity, making it particularly useful for electrochemical applications such as electrolytes in solid oxide fuel cells (SOFCs). The cubic phase lacks the transformation toughening mechanism present in the tetragonal phase but offers superior thermal and chemical stability.

The ability to stabilize YSZ in these different phases through the controlled addition of yttria allows for the tailoring of material properties to suit specific applications, ranging from structural components requiring high toughness to electrochemical devices needing high ionic conductivity.

Yttria Stabilized Zirconia Specification

| Physical Properties | |

| Density | 5.85 - 6.10 g/cc |

| Water Absorption | 0.00% |

| Mechanical Properties | |

| Hardness, Mohs | 8 |

| Modulus of Elasticity | 200 - 210 GPa |

| Compressive Strength | 2200 - 2500 MPa |

| Electrical Properties | |

| Electrical Resistivity | >= 1e+12 ohm-cm |

| Dielectric Constant | 29 |

| Dielectric Strength | 9.00 - 19.0 kV/mm |

| Dissipation Factor | 0.001 - 0.002 |

| Thermal Properties | |

| Thermal Conductivity | 2.20 - 2.50 W/m-K |

| Component Elements Properties | |

| Y2O3 | 3 - 12 % |

| ZrO2 | 88 - 97 % |

Yttria Stabilized Zirconia Applications

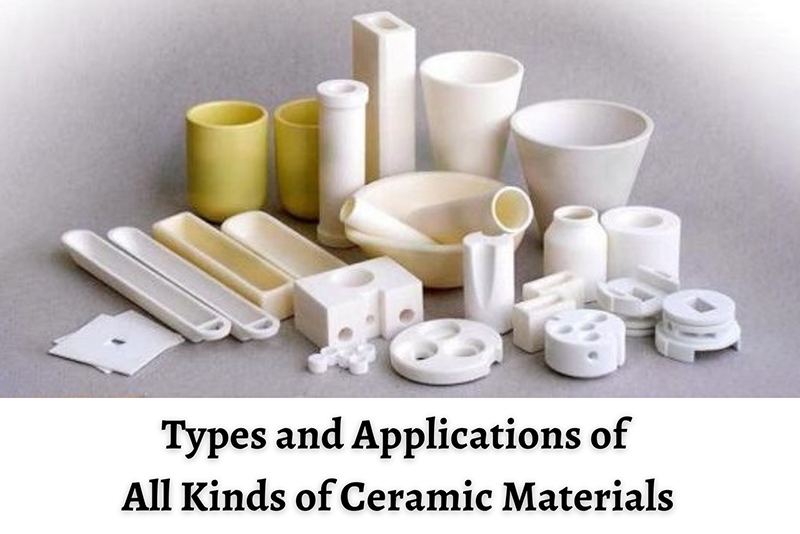

Yttria Stabilized Zirconia (YSZ) is renowned for its exceptional properties, including high strength, thermal stability, and resistance to wear and corrosion. These features make it a highly versatile material, leading to its application in various fields, from medical to industrial sectors. Below are expanded descriptions of its applications:

Dentistry: In the dental field, YSZ is widely used for the production of crowns and bridges due to its excellent biocompatibility, aesthetic qualities, and mechanical properties. Zirconia-based dental implants mimic the appearance of natural teeth while offering superior durability and resistance to fracture compared to other materials. Its ability to withstand the oral environment's corrosive effects without degrading makes it a preferred choice for long-term dental restorations.

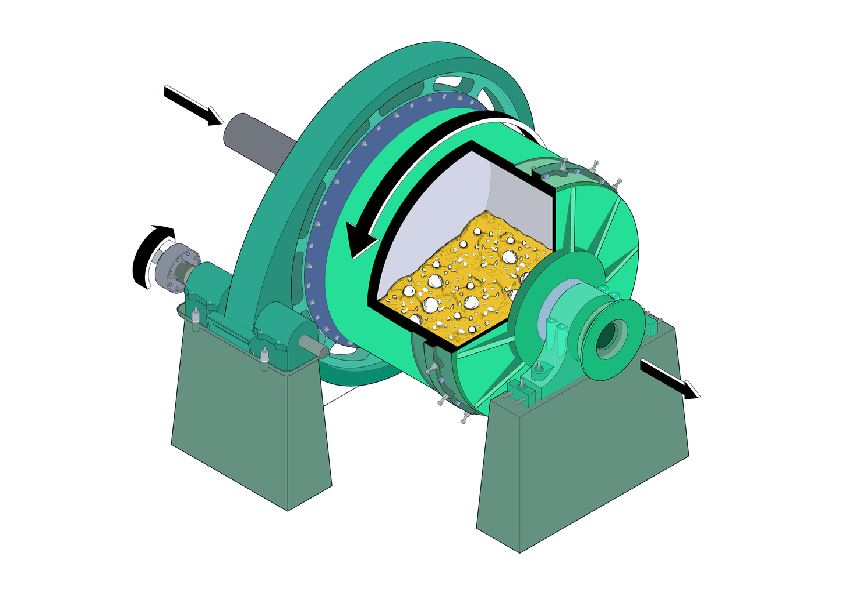

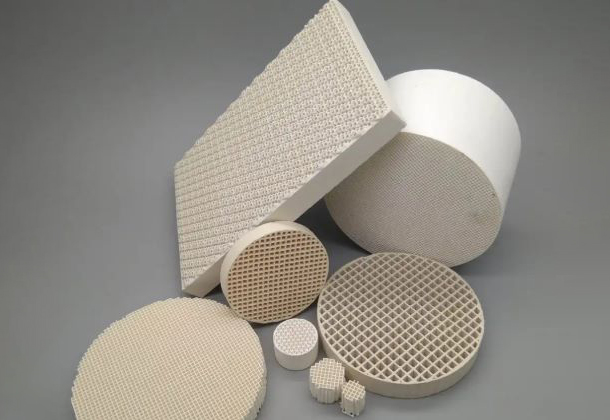

Refractory Material: As a refractory material, YSZ excels due to its high melting point and low thermal conductivity, making it ideal for use in high-temperature applications such as kiln linings, furnace components, and crucibles. Its resistance to thermal shock allows it to maintain structural integrity under rapid temperature changes, extending the lifespan of refractory installations.

Production of Solid Oxide Fuel Cells (SOFCs): YSZ's high ionic conductivity at elevated temperatures makes it an excellent electrolyte material for SOFCs. These fuel cells convert chemical energy directly into electrical energy through oxidation processes at high temperatures, with YSZ enabling efficient oxygen ion transport across the electrolyte layer. This application is critical for developing cleaner, more efficient energy conversion technologies.

DIY Cement: In the realm of do-it-yourself (DIY) projects, YSZ is sometimes added to cement mixtures to enhance their mechanical properties and durability. The addition of YSZ can improve the wear resistance and longevity of cement-based projects, from countertops to outdoor fixtures, making it a valuable component for both aesthetic and structural enhancements.

Coating: YSZ coatings are applied in various industrial applications to protect surfaces from wear, corrosion, and high temperatures. These coatings are particularly valuable in aerospace and automotive industries, where they are used on components such as turbine blades to enhance their thermal barrier properties. YSZ coatings significantly extend the service life of parts exposed to extreme conditions by providing a durable layer that withstands harsh environments.

These applications of Yttria Stabilized Zirconia highlight its importance across multiple domains, leveraging its unique properties to improve the performance and durability of products and systems in demanding applications.

ACM Ceramic Product Video

Your YSZ Ceramics Supplier

Advanced Ceramic Materials is a leading supplier of yttria-stabilized zirconia ceramic products of the highest quality for a wide range of applications. We are happy to provide advice on materials, design, and application. Feel free to contact us with any questions about YSZ or other ceramic materials that are not listed on the website.

| Chemical Formula | ZrO2+Y2O3 |

| Mechanical | |

| Density | 6.1 g/cm3 |

| Hardness | 17.6 GPa |

| Modulus of Elasticity | 200 GPa |

| Flexural Strength | 900-1200 MPa |

| Compressive Strength | 2000-2500 MPa |

| Poisson's Ratio | 0.25-0.30 |

| Fracture Toughness | 9 MPa m½ |

| Electrical | |

| Dielectric Strength | 10-15 kV/mm |

| Dielectric Constant | 25-30 |

| Volume Resistivity | 10^12 Ω·m |

| Thermal | |

| Coefficient of Thermal Expansion | 9.6 10^-6/K |

| Thermal Conductivity | 3 W/(m*K) |

| Specific Heat | 0.5 J/g·K |

| Shock Resistance | - |

| Maximum Working Temperature | 2400℃ |