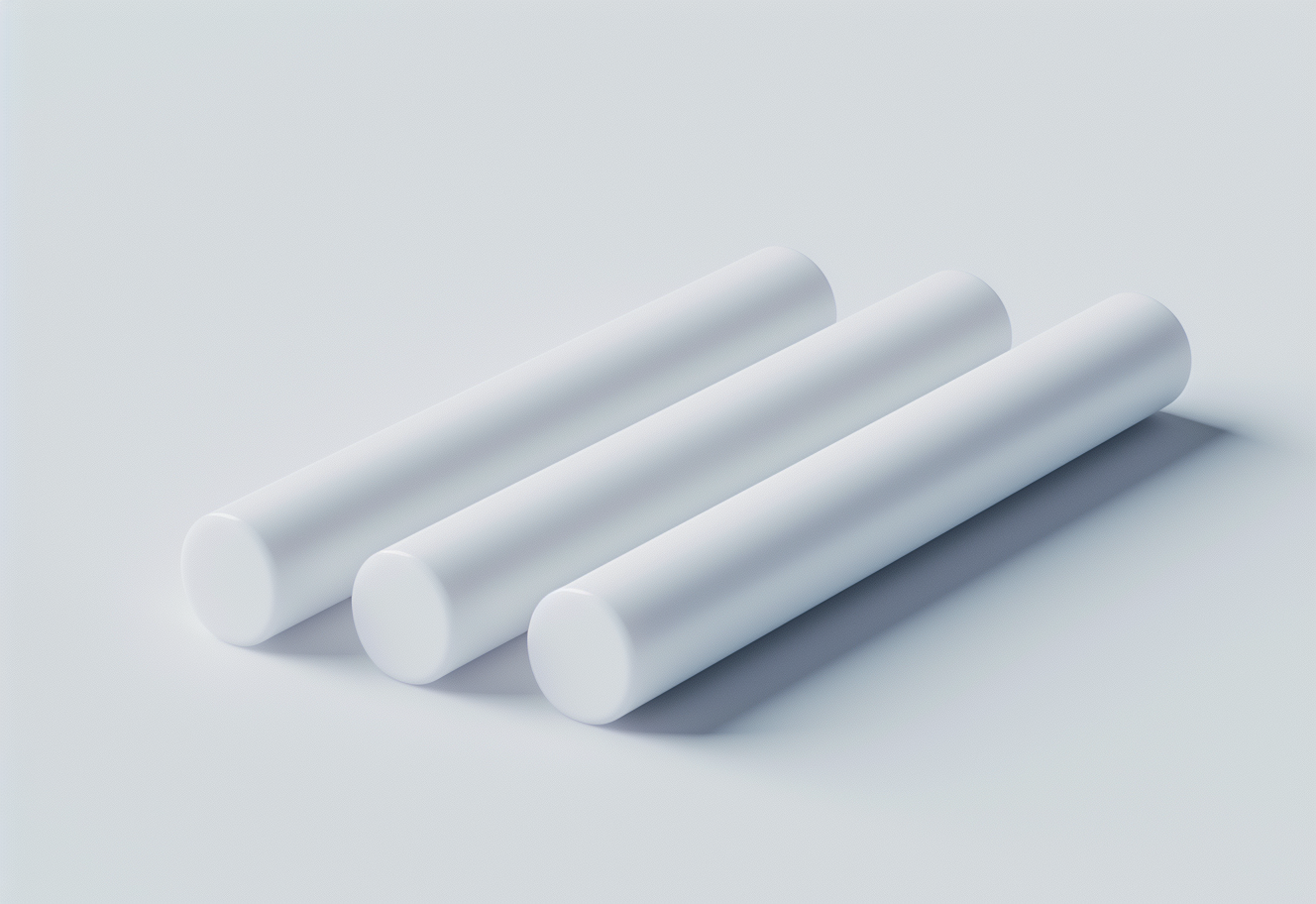

ZR6074 Hafnium Oxide Zirconia Bead

- Catalog No. ZR6074

- Main Compositions Zirconia, Hafnium Oxide, Yttria

- Diameter 0.3-3.2mm

- Form Bead

- Minimum Order Quantity (MOQ) 25kg/Package

Inquiry

ZR6074 Hafnium Oxide Zirconia Bead

Hafnium Oxide Zirconia Bead Overview

Hafnium Oxide Zirconia Beads are crafted from ultra-fine hydrolyzed zirconia powder, which is ground and dispersed into a nano-scale slurry before being formed into beads using a single-step titration rolling process. These beads are then pressurized and sintered at low temperatures, resulting in uniformity, higher strength, and reduced wear compared to traditionally rolled beads. The wear curve remains stable over time, making them ideal for the pure, efficient dispersion and grinding of materials in high-energy-density sand mills.

The beads' dense microcrystalline structure provides exceptional compressive strength, making them well-suited for use in high-energy density and high linear speed sand mills. The fine microcrystalline particles ensure minimal wear, measured in the parts-per-million (ppm) range, allowing for efficient, ultra-fine, and pure dispersion and grinding of materials even in challenging aqueous systems or acidic and alkaline environments.

Hafnium Oxide Zirconia Bead Specification

|

Specific Gravity |

>6.0kg/dm3 |

|

Bulk Density |

>3.6kg/L |

|

Mohs Hardness |

9 |

|

Vickers hardness |

1200kg/mm2 |

|

Compressive strength |

200kgf(2mm) |

|

Sphericity |

96% |

Chemical Composition

|

Composition |

ZrO2+HfO2 |

Y2O3 |

Al2O3/Others |

|

Wt% |

95 |

4.8 |

0.2 |

Specification

|

Model |

Diameter (φ) mm |

|

ND3 |

0.3~0.4 |

|

ND4 |

0.35~0.45 |

|

ND5 |

0.4~0.6 |

|

ND6 |

0.6~0.8 |

|

ND8 |

0.8~1.0 |

|

ND10 |

1.0~1.2 |

|

ND12 |

1.2~1.4 |

|

ND14 |

1.4~1.6 |

|

ND16 |

1.6~1.8 |

|

ND18 |

1.8~2.0 |

|

ND20 |

2.0~2.2 |

|

ND22 |

2.2~2.5 |

|

ND25 |

2.5~2.8 |

|

ND28 |

2.8~3.2 |

*Sizes can be tailored to meet specific customer requirements.

Hafnium Oxide Zirconia Bead Applications

- Carbon Materials: Ideal for processing carbon black, graphite, graphene, and carbon nanotubes, among others.

- Inkjet: Used in the production of office inks, UV inks, glass inks, ceramic inks, and textile inks.

- Printing Ink: Suitable for grinding flexographic inks, gravure inks, magnetic inks, and conductive inks.

- Coatings: Applied in the formulation of ship paints, motor vehicle paints, automotive paints, and aviation paints.

- Pesticide Suspension: Efficient in the dispersion of herbicides, insecticides, fungicides, and micro-fertilizers.

Hafnium Oxide Zirconia Bead Packing

25kg per drum, packaged in composite woven bags or drums.