An Introduction to Beryllium Oxide Ceramics

Introduction to Beryllium Oxide Ceramics

Beryllium oxide (BeO) ceramics, also historically known as glucina for their sweet-tasting soluble salts, are highly prized in advanced material applications due to their outstanding thermal conductivity and electrical resistivity. As a ceramic material, BeO combines the mechanical robustness of ceramics with exceptional heat dissipation capabilities, making it ideal for high-performance settings. Its unique properties stem from its crystalline structure, which provides both stability under extreme conditions and remarkable insulation capabilities.

BeO's utility spans across various high-tech industries, including aerospace and electronics, where materials are required to withstand extreme environments while maintaining performance. The compound's ability to operate at high temperatures without degradation, coupled with its high electrical insulation properties, makes it a critical component in applications ranging from electronic substrates to thermal management systems.

This introduction aims to explore the essential characteristics and applications of Beryllium Oxide ceramics, highlighting how they contribute to advancements in technology and industry. By understanding the foundational properties of BeO, we can appreciate its role in pushing the boundaries of material science and engineering.

Physical and Chemical Properties of Beryllium Oxide

Physical Properties: Beryllium Oxide (BeO) stands out in the ceramic materials family due to its impressive hardness and strength, rivaled only by materials like silicon carbide and boron nitride. With a density significantly lower than that of alumina, approximately 3.01 g/cc, BeO offers a unique balance of lightweight characteristics combined with robust mechanical properties. This makes it an ideal choice for applications demanding high strength-to-weight ratios. The fracture toughness of BeO, while lower than that of alumina, is adequately compensated by its high thermal conductivity and excellent dielectric strength.

Chemical Properties: Chemically, BeO is one of the most stable oxides available. It resists attack from molten metals and most acids and bases at high temperatures, making it exceptionally reliable in harsh environments. However, it exhibits reactivity with water vapor at temperatures above 1000°C, which can be a limitation in certain high-humidity applications. Despite this, its chemical inertness at normal temperatures allows it to perform well in a wide range of industrial processes.

BeO's resistance to thermal shock is another key feature. It can withstand rapid temperature changes that would typically fracture other ceramic materials. This property is particularly valued in applications such as electronic substrates and thermal barriers, where sudden temperature spikes are common.

Thermal and Electrical Characteristics of Beryllium Oxide

Thermal Properties: Beryllium Oxide's exceptional thermal conductivity is among the highest for any ceramic, reaching up to 330 W/mK, which allows it to effectively dissipate heat in applications requiring rapid cooling. This thermal conductivity surpasses that of other commonly used ceramics and is only second to diamond in the non-metal category, positioning BeO as an ideal material for heat sinks, electronic substrates, and other high-temperature components.

Electrical Properties: BeO also excels in its role as an electrical insulator. With a dielectric strength of around 10-16 kV/mm, it can withstand high voltage applications without risk of breakdown. This feature, coupled with its low dielectric constant, makes it suitable for high-frequency electronic applications where minimal electronic interference is crucial.

Table 1. Properties of Beryllium Oxide (BeO) for Industrial Applications

| Property Type | Property | Description |

|---|---|---|

| Physical | Density | 3.01 g/cc, lighter than alumina |

| Hardness & Strength | Comparable to silicon carbide and boron nitride | |

| Fracture Toughness | Lower than alumina, offset by high thermal conductivity | |

| Chemical | Stability | Resistant to most acids, bases, and molten metals |

| Reactivity | Reacts with water vapor above 1000°C | |

| Thermal Shock | Excellent resistance to rapid temperature changes | |

| Thermal | Conductivity | Up to 330 W/mK, among the highest for ceramics |

| Electrical | Dielectric Strength | 10-16 kV/mm, ideal for high voltage applications |

| Dielectric Constant | Low, beneficial for high-frequency electronic applications |

Industrial Applications of Beryllium Oxide

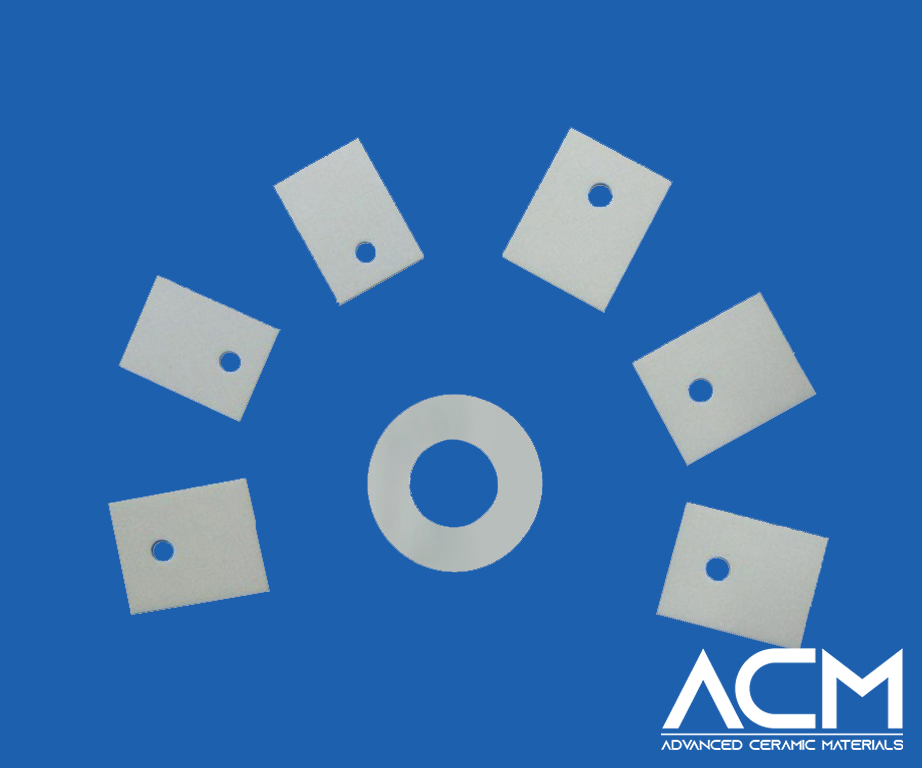

Electronics: In the realm of electronics, Beryllium Oxide is highly valued for its superior thermal management capabilities. It is commonly used in the production of electronic substrates and insulators that require efficient heat dissipation to maintain system stability and performance. BeO's high thermal conductivity ensures that heat generated by electronic components is quickly and effectively removed, enhancing the longevity and reliability of high-power and high-frequency devices.

Aerospace: In aerospace applications, BeO's lightweight yet strong properties are crucial. Its ability to withstand extreme environmental conditions — including high temperatures and radiation exposure — makes it an excellent choice for critical components in satellites and aircraft. These components often require materials that not only support structural integrity but also offer thermal management to protect sensitive instrumentation from overheating during operation.

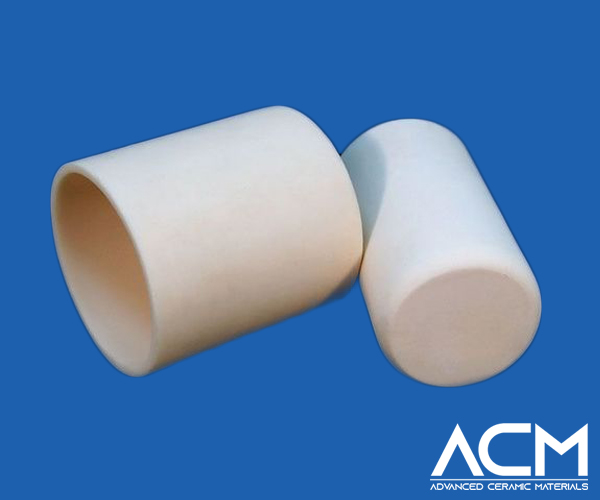

Metallurgical Applications: In metallurgical processes, BeO is used in high-temperature crucibles for the melting of rare and precious metals. These crucibles need to withstand temperatures that often exceed 2000°C and require a material that not only maintains integrity at such high temperatures but also does not react with the metals being processed. BeO's high melting point and excellent chemical stability make it an ideal choice for these applications, ensuring the purity and quality of the metals produced.

Toxicity and Safety Considerations in BeO Production

The production and handling of Beryllium Oxide (BeO) necessitate stringent safety measures due to its toxicity when inhaled as dust. BeO is known to be carcinogenic and can cause chronic berylliosis, a severe lung disease. This risk highlights the need for careful management during manufacturing processes, particularly when machining or handling the material in powder form.

Safety Protocols:

- Enclosed Systems: During the manufacturing and handling of BeO, enclosed systems are used to prevent the escape of dust into the atmosphere.

- Air Filtration: Facilities dealing with BeO are equipped with sophisticated air filtration systems to capture fine particles and prevent inhalation by workers.

- Personal Protective Equipment (PPE): Workers are required to wear appropriate PPE, including respirators, gloves, and protective clothing when in areas where BeO dust might be present.

Regulatory Compliance:

- Workplace Standards: There are strict regulatory standards governing the maximum allowable concentration of BeO in workplace environments to ensure worker safety.

- Waste Management: BeO materials must be disposed of in compliance with hazardous waste management protocols to prevent environmental contamination.

Health Monitoring:

- Regular health checks and monitoring for signs of berylliosis are mandatory for workers handling BeO to ensure early detection and management of any health issues arising from exposure.

Despite these challenges, with proper safety protocols, BeO remains a valuable material in numerous high-tech applications. The ceramic industry continues to research and implement safer handling techniques and processing methods to mitigate the risks associated with BeO, aiming to protect workers and the environment while harnessing the material's benefits.

Comparative Analysis with Other Ceramics

Beryllium Oxide (BeO) ceramics offer unique advantages when compared to other advanced ceramics like alumina, silicon carbide, and aluminum nitride, particularly in terms of thermal conductivity and electrical insulation. However, these benefits come with considerations of cost, performance, and safety that can influence material selection depending on the application.

Cost and Availability: BeO is generally more expensive than alumina due to its superior properties and the complexities involved in safely manufacturing and handling the material. Although less expensive than silicon carbide and comparable to aluminum nitride in cost, the overall expenditure for BeO extends beyond initial costs due to safety measures required during handling.

Performance: In terms of thermal conductivity, BeO surpasses alumina and is comparable to silicon carbide, making it ideal for applications requiring efficient heat dissipation. Its electrical insulation capabilities are superior to those of aluminum nitride, which, combined with its thermal properties, makes it highly valuable in electronic and aerospace applications where both high insulation and thermal management are critical.

Safety: The toxicity of BeO is a significant drawback compared to other ceramics. Alumina and aluminum nitride do not pose the same health risks, making them more suitable for applications where BeO's specific advantages are not strictly necessary. Silicon carbide, while also used in high-performance environments, does not carry the same health risks associated with beryllium exposure.

Conclusion

Beryllium Oxide (BeO) ceramics stand out for their exceptional properties, making them indispensable in various high-tech applications. The material's superior thermal conductivity and electrical insulation capabilities enable it to perform in demanding environments such as electronics and aerospace. Despite the health risks associated with its powder form, ongoing research and strict safety measures continue to make BeO a viable option. Understanding the unique attributes of BeO and comparing them with other ceramics is crucial for choosing the right material for specific needs. Advanced Ceramic Materials (ACM) remains at the forefront, providing high-quality BeO ceramics to meet diverse industrial demands.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments