Boron Nitride Coatings: The Solution for Molten Metal Applications

Introduction

Working with molten metals in an industrial setting is never a simple job. These metals reach very high temperatures that can damage equipment if not properly controlled [1]. The heat alone is a major concern. In addition, molten metals behave in unpredictable ways. They tend to stick to surfaces, leading to clogging and buildup [2]. When exposed to the air, they quickly form dross and byproducts as a result of oxidation. Moreover, the reactive nature of these metals calls for special materials that can resist corrosion. Over the years, transmission of heat, chemical reactions, and stressful physical contact have all forced engineers to look for protective measures that work effectively.

Boron nitride coatings have emerged as a solution that meets many of these needs. These coatings are designed to keep the equipment safe by providing layers of defense against the hostile environment created by molten metals. In this discussion, we look at the basic protective functions of these coatings and touch on why boron nitride is a helpful addition. Drawing from decades of experience in materials science and industrial applications, the following sections aim to provide clear and down-to-earth insights on the subject.

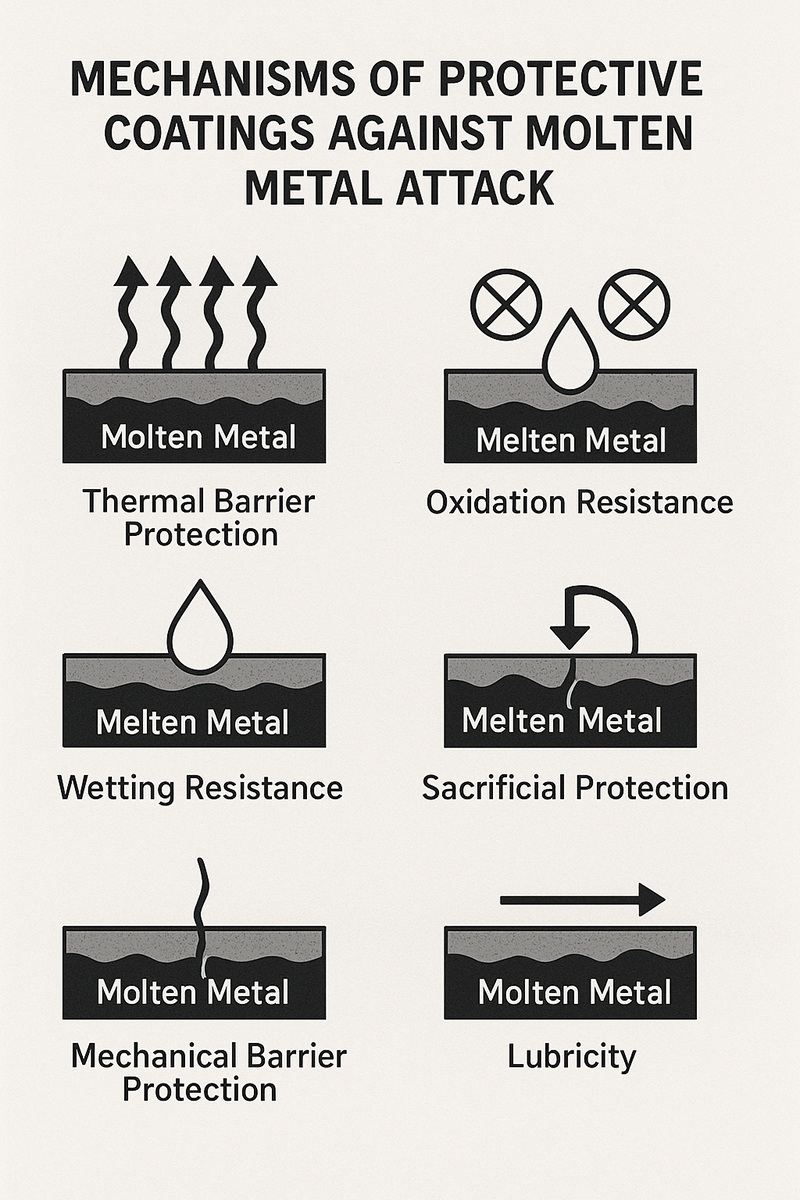

Mechanisms of Protective Coatings Against Molten Metal Attack

When molten metals come into contact with industrial equipment, it is essential to have a shield in place. Protective coatings play this role by offering multiple layers of defense. From acting as a thermal barrier to resisting unwanted chemical reactions, the coatings work on several fronts. Each layer is designed to tackle a specific aspect of the problem, and the following sections describe these functions in everyday language and simple terms.

Thermal Barrier Protection

One of the most important roles of a protective coating is to keep heat from damaging the equipment. Molten metals generate enormous amounts of heat that can quickly transfer to the underlying surface. A good coating reduces this heat transfer by acting like a blanket that insulates the substrate [3]. This helps keep the metal part of the machine safe from thermal degradation and potential failure. In simple terms, the coating means the underlying surface does not come into direct contact with extreme heat, thereby extending the lifespan of the equipment.

For instance, a furnace lining coated with boron nitride will maintain lower temperatures on the equipment face, reducing the risk of fatal thermal expansion or cracking. This is particularly crucial when the equipment is in constant contact with molten metal streams in high-production environments.

Oxidation Resistance

Oxidation is a process that can quickly deteriorate any metal exposed to high temperatures and air. Coatings enhanced with elements such as aluminum and chromium are known to form a thin but robust oxide layer [4]. This layer acts as a shield against further oxidation and prevents corrosive reactions. In situations where molten metals are in use, this barrier is essential for avoiding costly repairs or unscheduled downtime.

Imagine a casting mold that must withstand repeated cycles of high heat and reactive metal. Without a proper barrier, oxidation would quickly lead to surface damage. With a coating that builds up a stable oxide layer, the risk drops considerably.

Wetting Resistance

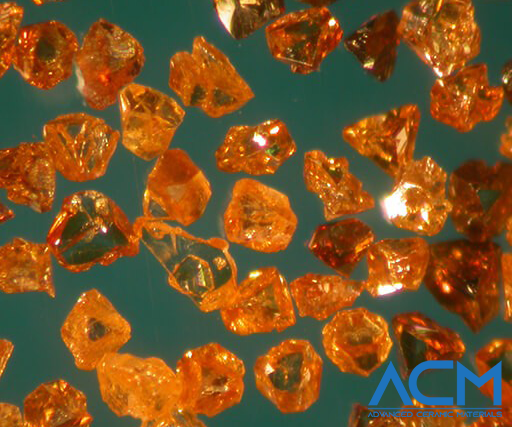

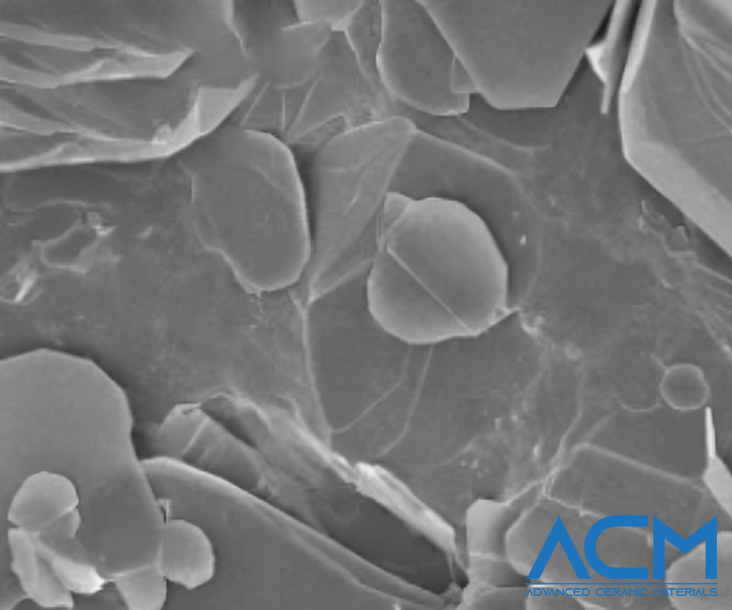

Another challenge when working with molten metals is wetting. Molten metal that spreads too easily can seep into small gaps and bond with the equipment surface, making it hard to remove. Protective coatings with non-wettable properties, such as those including boron nitride, change the surface energy of the equipment and significantly reduce metal adhesion [5]. This prevents the metal from sticking readily. As a result, applications like die-casting or welding see less buildup and easier maintenance.

A practical example occurs in a foundry where molten aluminum is routinely poured into molds. If the surface of the mold is treated with a high-quality coating, the aluminum does not adhere as strongly. The reduced adhesion means smoother operation and less downtime for cleaning and maintenance.

Sacrificial Protection

Some coatings are designed to sacrifice themselves to protect the underlying equipment. In this approach, the coating reacts with the molten metal instead of the metal of the equipment. Materials such as specific ceramics or magnesium oxide are known to bond with molten metal and form a protective slag. This slag, once formed, acts as a barrier, stopping further reactions between the molten metal and the substrate.

In practical settings, such as metal casting, a sacrificial coating may erode slightly with each use. However, this slight loss is a fair trade for the extended life of the major equipment parts. The gradual and controlled reaction minimizes damage and helps maintain the integrity of critical components.

Mechanical Barrier Protection

Besides thermal and chemical hurdles, the physical impact of flowing molten metal presents its own set of challenges. Protective coatings also serve as a mechanical barrier, offering a sturdy physical shield that reduces direct contact. This layer absorbs some of the force of the impacting metal and smoothens out the stress caused by thermal expansion. Maintaining an intact and well-adhered coating is key in such situations. In cases where the metal moves quickly, a robust coating can prevent chipping or cracking of the base material.

For example, in high-speed casting operations, where molten metal strikes multiple surfaces rapidly, a well-designed mechanical barrier keeps the equipment free from immediate damage. The physical layer is as important as the chemical resistance it provides.

Lubricity

A unique benefit of boron nitride coatings is their natural lubricity. In plain language, they reduce the friction between moving surfaces. This low friction helps in preventing the molten metal from sticking or reacting too strongly with the equipment. The smoother the metal flows, the less likely it is that microcracks will form. Over time, this can mean fewer interruptions and more consistent performance of the machinery.

This lubricious property is especially beneficial in processes where metal movement is continuous and must be controlled precisely. Even a slight improvement in the smoothness of the metal flow can lead to noticeable improvements in long-term equipment performance.

Factors Influencing Coating Performance

A protective coating's ability to withstand the harsh environment of molten metals depends on several factors. Here are the key points to consider:

- Material Composition: The ingredients in the coating determine how well it can resist heat, chemical attack, and oxidation. A well-balanced blend is necessary for enduring the tricky conditions of molten metal contact.

- Thickness: A thicker coating might offer more protection but is also more prone to cracking, especially when it expands or contracts with temperature changes. Finding the right thickness is always a balancing act in industrial applications.

- Application Method: The way the coating is applied—whether through thermal spraying, physical vapor deposition, or chemical vapor deposition—plays a big role. A uniform layer with strong adhesion is essential for effective long-term performance. Inconsistent application can lead to weak spots, which may eventually lead to equipment failure.

These properties are not just abstract ideas but have practical impacts. For example, in one plant, a change from a poorly applied coating to one with more consistent thickness and proper bonding resulted in a marked increase in equipment life. Workers noticed fewer interruptions and fewer repairs needed over time.

Conclusion

In summary, boron nitride coatings offer a multi-pronged defense against the challenges posed by molten metals. By acting as thermal barriers, preventing oxidation, reducing undesirable wetting, and providing both sacrificial and mechanical protection, these coatings address most issues encountered in high-temperature industrial processes. Their inherent lubricity gives them an extra edge by keeping the moving metal and surfaces from harming each other.

From an experienced perspective, proper care in choosing and applying the coating is as important as the technology behind it. When used in the right thickness and applied uniformly, boron nitride-based coatings can greatly extend the service life of critical equipment. For industries that work with molten metal day in and day out, this can mean lower maintenance costs and fewer production delays.

Finally, if you are considering a high-performance boron nitride solution for your molten metal applications, take a closer look at what Advanced Ceramic Materials (ACM) has to offer. Their reliable, well-proven materials have served many industries for years, and they remain a trusted supplier for protection against even the most extreme conditions.

Reference:

[1] N. Eustathopoulos, M.G. Nicholas, B. Drevet, Wettability at High Temperatures, Pergamon, 1999 – Chapter on molten metal temperatures and thermal impact.

[2] S. Seetharaman, Fundamentals of Metallurgy, Woodhead Publishing, 2005 – Section on molten metal wetting and buildup behavior.

[3] R. F. Davis, “Boron Nitride: Structure, Properties, and Applications,” Ceramic Bulletin, 1987 – Thermal barrier characteristics of BN coatings.

[4] G. Y. Lai, High-Temperature Corrosion and Materials Applications, ASM International, 2007 – Oxidation behavior of Al‑ and Cr‑containing coatings.

[5] M. K. Meyer et al., “Non‑Wetting Behavior of BN‑Based Coatings with Molten Aluminum,” Journal of Materials Engineering and Performance, 2003.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments