Introduction to Magnesium Oxide Stabilized Zirconia Ceramics

Magnesium oxide stabilized zirconia (MgO-ZrO2) ceramics are gaining significant attention in various industries due to their exceptional properties, particularly at high temperatures. Zirconia ceramics, known for their high melting point and superior mechanical properties, are often used in demanding applications. However, their performance can be improved by stabilizing them with magnesium oxide. This article explores the advantages and high-temperature resistance of MgO-stabilized zirconia ceramics and their diverse applications in industries such as aerospace, medical, and mechanical engineering.

Basic Concept of Magnesium Oxide Stabilized Zirconia Ceramics

Zirconia (ZrO2) is a well-known ceramic material that offers excellent thermal, mechanical, and electrical properties. However, at high temperatures, zirconia undergoes a phase transformation from tetragonal to monoclinic, which leads to a reduction in mechanical strength and increases the risk of fracture. To overcome this limitation, stabilizing agents like magnesium oxide (MgO) are introduced.

When zirconia is stabilized with magnesium oxide, it enhances the material's phase stability, preventing this phase transformation and improving its overall performance. MgO stabilizes the tetragonal phase of zirconia, allowing it to retain its high strength, toughness, and wear resistance at elevated temperatures. The resulting ceramic, MgO-ZrO2, is often used in applications that require high thermal stability and structural integrity.

Advantages of Magnesium Oxide Stabilized Zirconia Ceramics

1. High-Temperature Stability

One of the key advantages of MgO-ZrO2 ceramics is their remarkable high-temperature stability. Magnesium oxide significantly improves the temperature resistance of zirconia, preventing it from undergoing phase changes at elevated temperatures. This makes MgO-stabilized zirconia ideal for use in high-temperature environments where other materials might fail due to thermal instability.

2. Outstanding Mechanical Properties

MgO-ZrO2 ceramics are known for their exceptional mechanical properties. They possess high strength, hardness, and fracture toughness, making them ideal for industrial applications that require durable and reliable materials. This high strength is maintained even at elevated temperatures, providing stability and performance in harsh environments.

3. Corrosion Resistance

Magnesium oxide stabilized zirconia exhibits excellent resistance to chemical corrosion, including resistance to strong acids, alkalis, and high-temperature oxidation. This property is particularly beneficial in industries such as chemical processing, where materials are often exposed to aggressive environments.

4. Thermal Expansion Coefficient Matching

One of the challenges in materials science is matching the thermal expansion coefficients of different materials in a composite structure. MgO-ZrO2 ceramics have a thermal expansion coefficient that closely matches certain metals, which makes them ideal for use in metal matrix composites. This compatibility enhances the durability and performance of materials in high-temperature environments.

5. Thermal Shock Resistance

Compared to pure zirconia, MgO-ZrO2 ceramics exhibit superior thermal shock resistance. This means they can withstand rapid temperature fluctuations without cracking or failing, making them suitable for applications where materials are subjected to sudden temperature changes, such as in jet engines or combustion chambers.

High-Temperature Resistance of Magnesium Oxide Stabilized Zirconia Ceramics

The high-temperature resistance of MgO-ZrO2 ceramics is one of their most significant attributes. At elevated temperatures, pure zirconia undergoes a phase transformation from tetragonal to monoclinic, which reduces its mechanical strength and can lead to cracking. However, when stabilized with magnesium oxide, the tetragonal phase is stabilized, allowing the material to retain its mechanical properties even at high temperatures.

MgO stabilizes zirconia by preventing the undesirable phase transition, thereby increasing its resistance to thermal expansion and improving its ability to withstand high thermal stresses. This makes MgO-ZrO2 ceramics ideal for applications in high-temperature environments such as furnace linings, gas turbines, and exhaust systems, where other materials might fail due to phase changes.

Applications of Magnesium Oxide Stabilized Zirconia Ceramics

Due to their superior thermal, mechanical, and chemical properties, MgO-stabilized zirconia ceramics are widely used across various industries. Some of the key applications include:

- High-Temperature Structural Materials: In industries like aerospace, energy, and metallurgy, MgO-ZrO2 ceramics are used for components exposed to extreme temperatures, such as turbine blades, heat shields, and furnace linings.

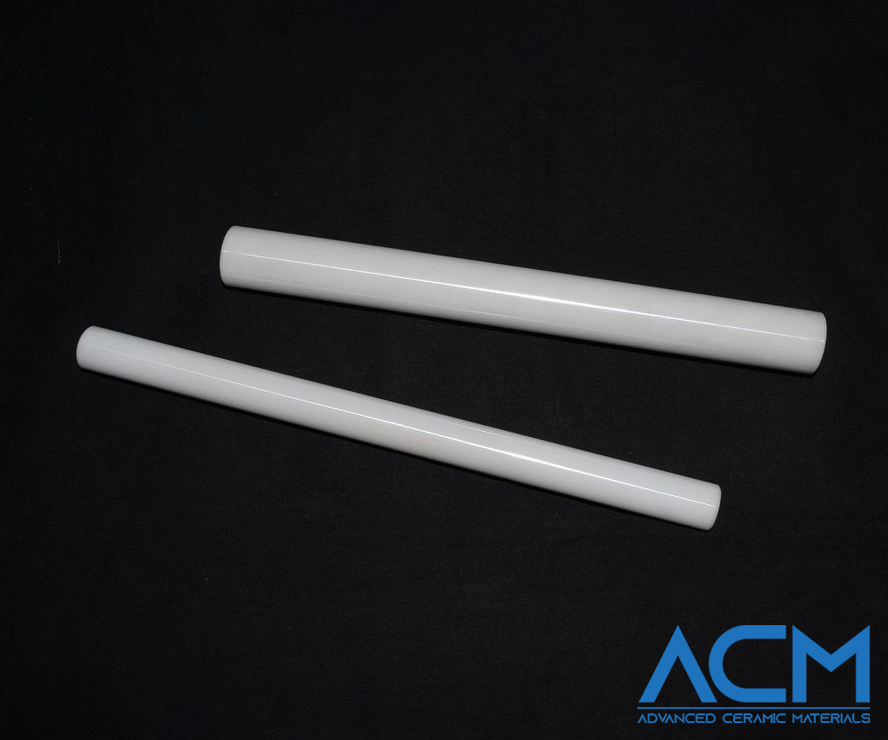

- Mechanical Industry: These ceramics are also utilized in mechanical components like cutting tools, bearings, and wear-resistant parts, where strength and durability are essential.

- Electrical Industry: MgO-ZrO2 ceramics are used as insulators due to their high dielectric strength and thermal stability.

- Medical Applications: Thanks to their biocompatibility, MgO-stabilized zirconia is used in the medical field for prosthetics, dental implants, and artificial joints, offering both durability and resistance to wear and corrosion.

Conclusion

Magnesium oxide stabilized zirconia ceramics stand out for their excellent high-temperature stability, outstanding mechanical properties, and versatility in various applications. Their ability to maintain structural integrity and performance in extreme environments makes them invaluable in the aerospace and healthcare industries. As technology advances, the potential for even broader applications of MgO-ZrO2 ceramics continues to grow, promising to play a critical role in the development of future high-performance materials.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- Boron Nitride in Cosmetics: Enhancing Performance and Sensory Appeal

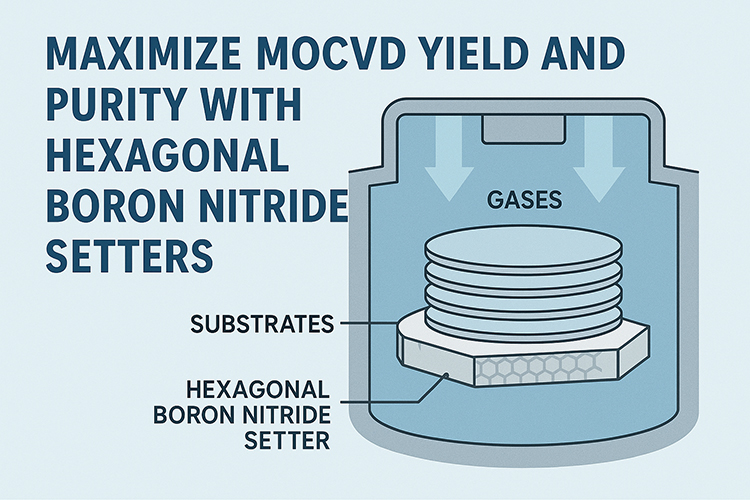

- Maximize MOCVD Yield and Purity with Hexagonal Boron Nitride Setters

- What Are the Advantages and Uses of Boron Nitride Ceramic Sheet?

- The Compression Annealing Advantage for Pyrolytic Boron Nitride

- Beyond Insulation: The Surprising Spectrum of Ceramic Thermal Conductivity