Pressureless Sintered Silicon Carbide Properties

Pressureless Sintered Silicon Carbide (SSiC) is manufactured from high-purity ultra-fine silicon carbide powder (sub-micron) in a vacuum furnace at the temperature of 2100℃ – 2200℃. Very strong sintering bonds between the material grains are formed. Direct Sintered SiC is a better grade than Reaction Bonded SiC and is commonly specified for high-temperature work and hard-faced seal components.

Available Form: Tube, Plate, Ball, Seal Ring, Nozzle, Gasket, etc.

Mechanical Properties of Pressureless Sintered Silicon Carbide

|

Property |

Units |

Value |

|

Density |

g/cm3 |

3.1-3.2 |

|

Vickers hardness |

HV0.5 |

2500 |

|

Purity (SiC Percentage) |

% |

99 |

|

Porosity |

% |

<0.2 |

|

Fracture Toughness |

MPa·m1/2 |

4 |

|

Compressive Strength |

MPa |

3000 |

|

Flexural Strength |

MPa |

400 |

|

Young’s Modulus of Elasticity |

GPa |

410 |

|

Poisson’s Ratio ν |

0.15 |

|

|

Thermal Conductivity |

W/m.k |

100-120 |

|

Thermal Expansion Coefficient |

i/℃ |

4*10-6 |

|

Maximum Use Temperature |

℃ |

1600 |

![]()

Related reading: Silicon Carbide: Reaction Sintering vs. Pressureless Sintering

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

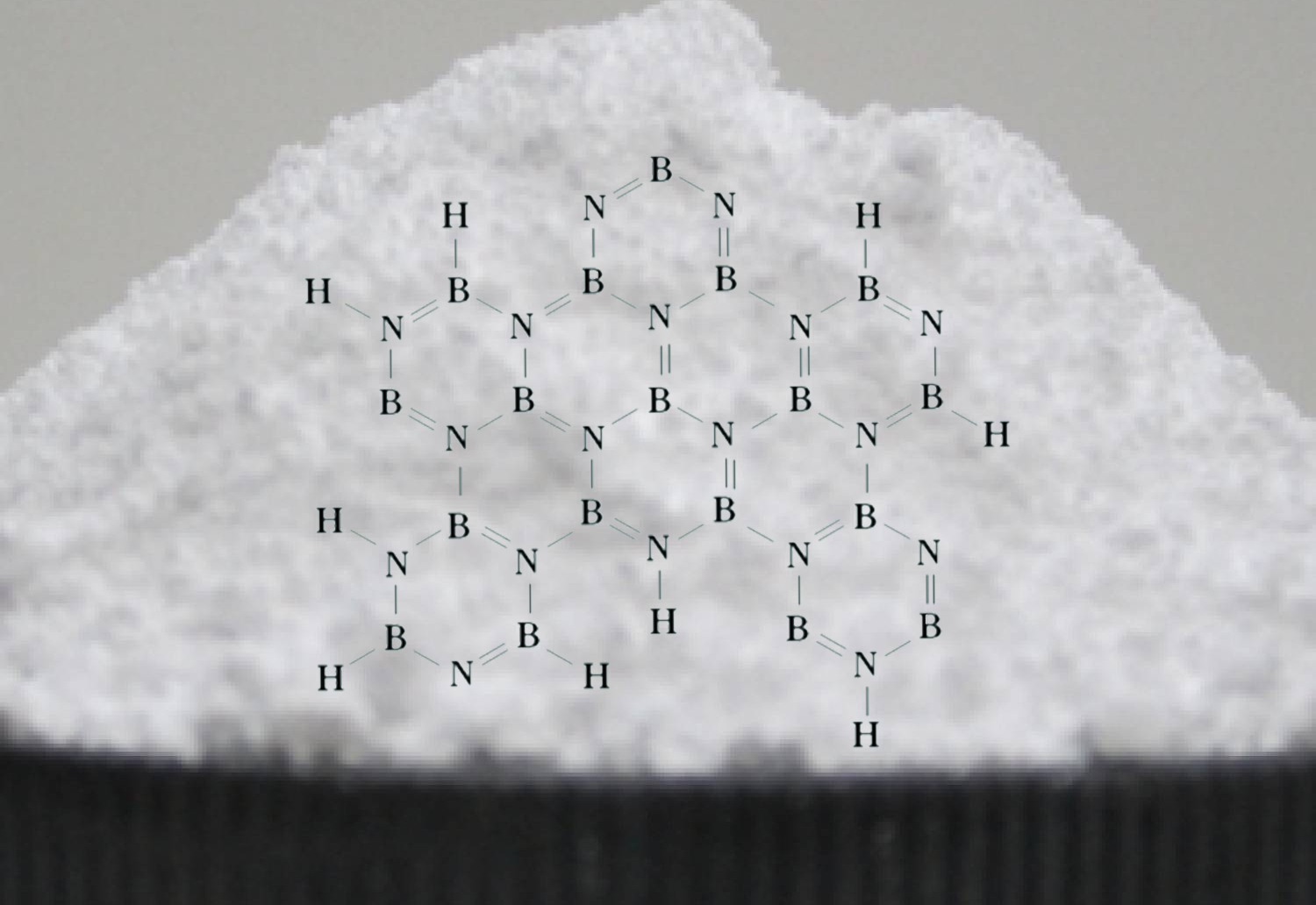

- Boron Nitride in Cosmetics: Enhancing Performance and Sensory Appeal

- Maximize MOCVD Yield and Purity with Hexagonal Boron Nitride Setters

- What Are the Advantages and Uses of Boron Nitride Ceramic Sheet?

- The Compression Annealing Advantage for Pyrolytic Boron Nitride

- Beyond Insulation: The Surprising Spectrum of Ceramic Thermal Conductivity