The 6 Most Popular Types of Silicon Carbide Heating Elements

Introduction

Silicon carbide (SiC) is a robust ceramic material widely recognized for its high thermal conductivity and excellent electrical resistance, making it an ideal candidate for heating elements in various industrial applications. These heating elements are essential components in electric furnaces and other heating devices, playing a crucial role in industries ranging from metallurgy to ceramics and electronics. The unique properties of SiC allow for efficient heating operations with precise temperature control, making them preferable in settings that demand high durability and performance. This article explores the different types of silicon carbide heating elements, focusing on their design, specifications, and applications, providing valuable insights for selecting the appropriate type based on specific industrial needs.

QUICK GUIDE:

- 1. SC Type Silicon Carbide Heating Elements

- 2. H Type Silicon Carbide Heating Elements

- 3. W Type Silicon Carbide Heating Elements

- 4. DM Type Silicon Carbide Heating Elements

- 5. SCR Type Silicon Carbide Heating Elements

- 6. GC Type Silicon Carbide Heating Elements

- Comparison of SiC Heating Element Types

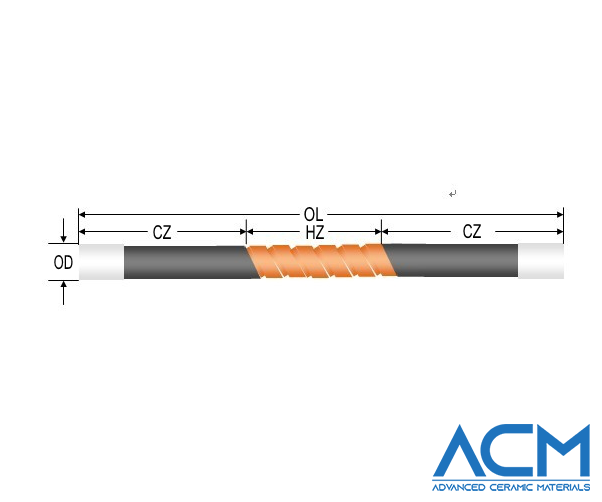

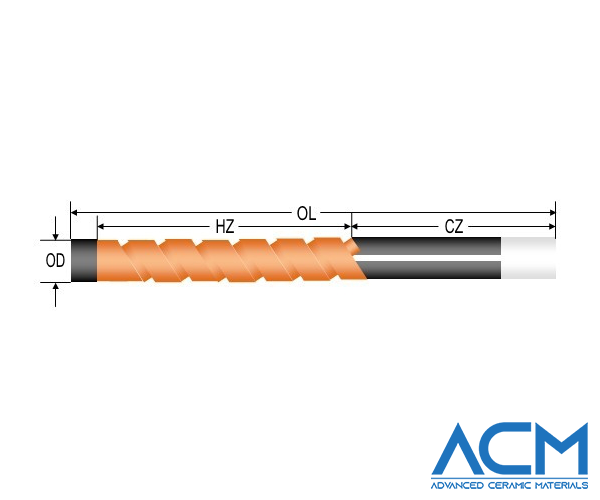

1. SC Type Silicon Carbide Heating Elements

The SC Type Silicon Carbide Heating Element is known for its Single Spiral configuration, a design that optimizes the material's high electrical conductivity and thermal efficiency. This type of element is made entirely of ceramic, offering not only high resistance to electrical currents but also an ability to sustain and distribute heat effectively across its surface.

Specifications:

- Material: Silicon Carbide

- Color: Black

- Density: 3.2 g/cm³

- Hardness: 9.5 on the Mohs scale

- Specific Heat: 0.17 kcal/kg

- Size: Diameters range from 8-40mm; Lengths from 220-4000mm

- Working Temperature Range: 1200-1400°C

- Degree Expansion Coefficient: 5*10^-6

These elements are adept at providing high-temperature conditions essential for various industrial processes due to their durable structure and precise temperature control capabilities. The SC type is particularly effective in systems where uniform heat distribution is crucial, such as large box furnaces and trolley furnaces used in metal treatment and ceramics.

Applications:

The SC Type excels in applications requiring consistent heating and minimal temperature variance across large surfaces. It is especially suitable for the bottom or side heating of large-scale industrial furnaces where spatial temperature uniformity is a key operational requirement. Its robust nature also makes it ideal for long-term use in environments where regular replacement of heating elements is logistically challenging or economically unfeasible.

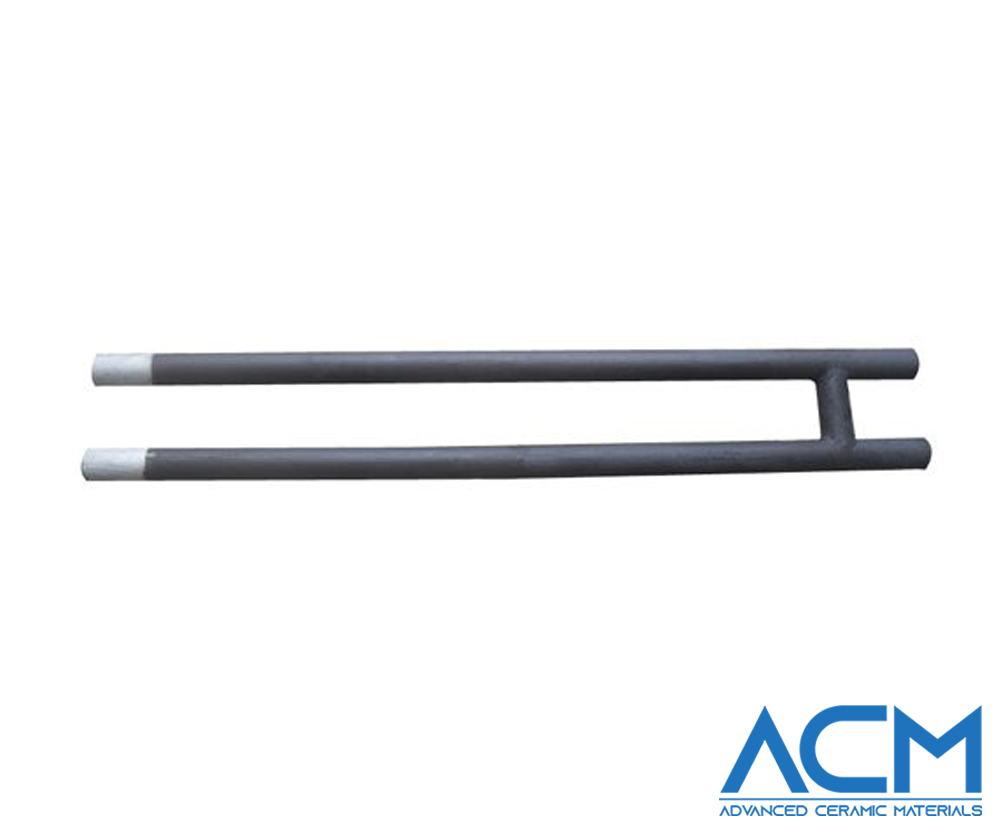

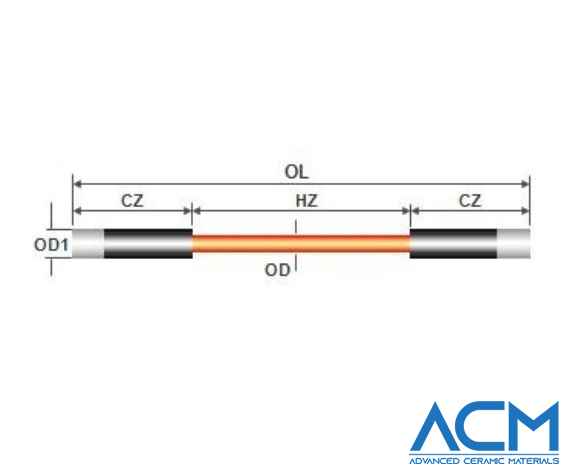

2. H Type Silicon Carbide Heating Elements

The H Type Silicon Carbide Heating Element is characterized by its unique hollow tubular design which includes a thickened end. This configuration enhances the element's ability to withstand rapid temperature changes without deforming, making it especially valuable in applications that require high durability under fluctuating thermal conditions.

Specifications:

- Material: Silicon Carbide

- Color: Black

- Density: 3.2 g/cm³

- Hardness: 9.5 on the Mohs scale

- Specific Heat: 0.17 kcal/kg

- Size: Diameters range from 8-40mm; Lengths from 220-4000mm

- Degree Expansion Coefficient: 5*10^-6

The design of the H Type heating element allows it to maintain structural integrity and chemical stability even under high thermal stress. Its properties are particularly suited to the demands of industries that process materials sensitive to thermal shock.

Applications:

The H Type is widely used in the electric heating of environments within the glass, chemicals, and electronic materials sectors. Its capacity to provide consistent and controlled heat makes it ideal for processes that require precise temperature maintenance and reliability, ensuring high-quality production outcomes.

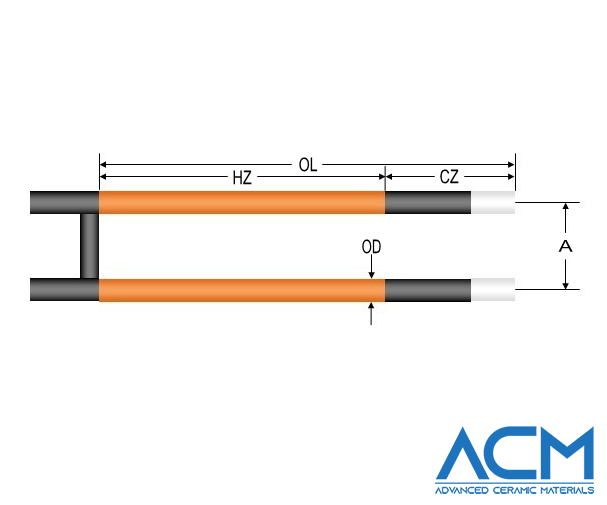

3. W Type Silicon Carbide Heating Elements

The W Type Silicon Carbide Heating Element stands out due to its assembly of one silicon carbide rod connected to three high-purity silicon carbide rods at one end, forming a W-shaped configuration. This design is intended for horizontal installation and is particularly effective in maintaining uniform heating over large surface areas.

Specifications:

- Material: Silicon Carbide

- Color: Black

- Density: 3.2 g/cm³

- Hardness: 9.5 on the Mohs scale

- Specific Heat: 0.17 kcal/kg

- Size: Diameters range from 8-40mm; Lengths from 220-4000mm

- Degree Expansion Coefficient: 5*10^-6

This structure not only provides exceptional durability and resistance to thermal shock but also facilitates efficient energy use and even distribution of heat, critical in large-scale industrial applications.

Applications:

The W Type is extensively utilized in the production of float glass and other chemical processes where precise and uniform temperature control is necessary. Its robust design allows for direct connection to a three-phase power supply, simplifying electrical arrangements and enhancing overall operational efficiency in industries such as electronics and chemical manufacturing.

4. DM Type Silicon Carbide Heating Elements

The DM Type Silicon Carbide Heating Element features a design optimized for applications requiring precise temperature control and high thermal stability. This type incorporates a hollow tubular heating part with a thickened end, similar to other types but with specific enhancements aimed at high-temperature accuracy.

Specifications:

- Material: Silicon Carbide

- Color: Black

- Density: 3.2 g/cm³

- Hardness: 9.5 on the Mohs scale

- Specific Heat: 0.17 kcal/kg

- Size: Diameters range from 8-40mm; Lengths from 220-4000mm

- Working Temperature Range: 1200-1400°C

- Degree Expansion Coefficient: 5*10^-6

DM Type elements are engineered to maintain a consistent temperature, a critical feature for processes where even slight temperature variations can impact product quality.

Applications:

This type is commonly used in industrial furnaces and high-temperature processes including metal heat treatment, ceramic and glass production, and semiconductor manufacturing. Its ability to provide stable and controlled heat makes it ideal for sectors that demand precise temperature management for optimal results.

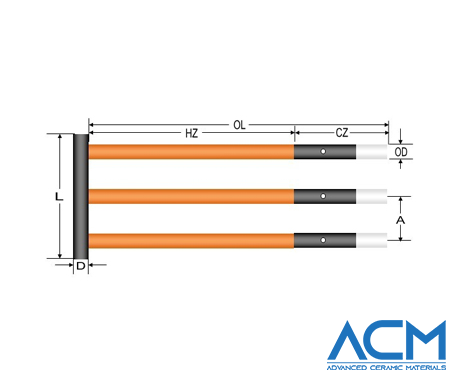

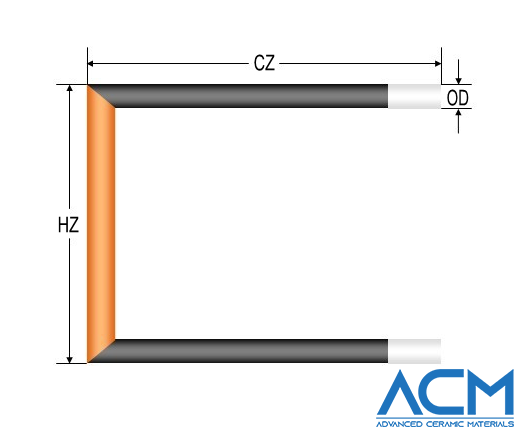

5. SCR Type Silicon Carbide Heating Elements

The SCR Type Silicon Carbide Heating Element is designed based on a calculated approach to enhance the properties of U-shaped silicon carbide rods. This type offers excellent temperature control and energy efficiency, making it suitable for technically demanding applications.

Specifications:

- Material: Silicon Carbide

- Color: Black

- Density: 3.2 g/cm³

- Hardness: 9.5 on the Mohs scale

- Specific Heat: 0.17 kcal/kg

- Size: Diameters range from 8-40mm; Lengths from 220-4000mm

- Working Temperature Range: 1200-1400°C

- Degree Expansion Coefficient: 5*10^-6

SCR Type elements are favored in high-end applications that require sophisticated thermal management, including aerospace, advanced electronics manufacturing, and specialized industrial heating.

Applications:

They are particularly valued in environments where automated temperature adjustments are necessary to align with specific manufacturing processes, ensuring precision and efficiency in high-stakes production settings.

6. GC Type Silicon Carbide Heating Elements

GC Type Silicon Carbide Heating Elements are known for their hollow tubular structure and thickened ends, designed to handle rapid cold and heat without deformation. This type is engineered for robustness and chemical stability under demanding conditions.

Specifications:

- Material: Silicon Carbide

- Color: Black

- Density: 3.2 g/cm³

- Hardness: 9.5 on the Mohs scale

- Specific Heat: 0.17 kcal/kg

- Size: Diameters range from 8-40mm; Lengths from 220-4000mm

- Degree Expansion Coefficient: 5*10^-6

The GC Type's design is particularly suited for continuous, high-temperature operations across various industries.

Applications:

This element is extensively used in the manufacture of glass, chemicals, and electronic materials where consistent heating and thermal resilience are required. Its ability to maintain a stable temperature and resist environmental stresses makes it a preferred choice for many industrial heating applications.

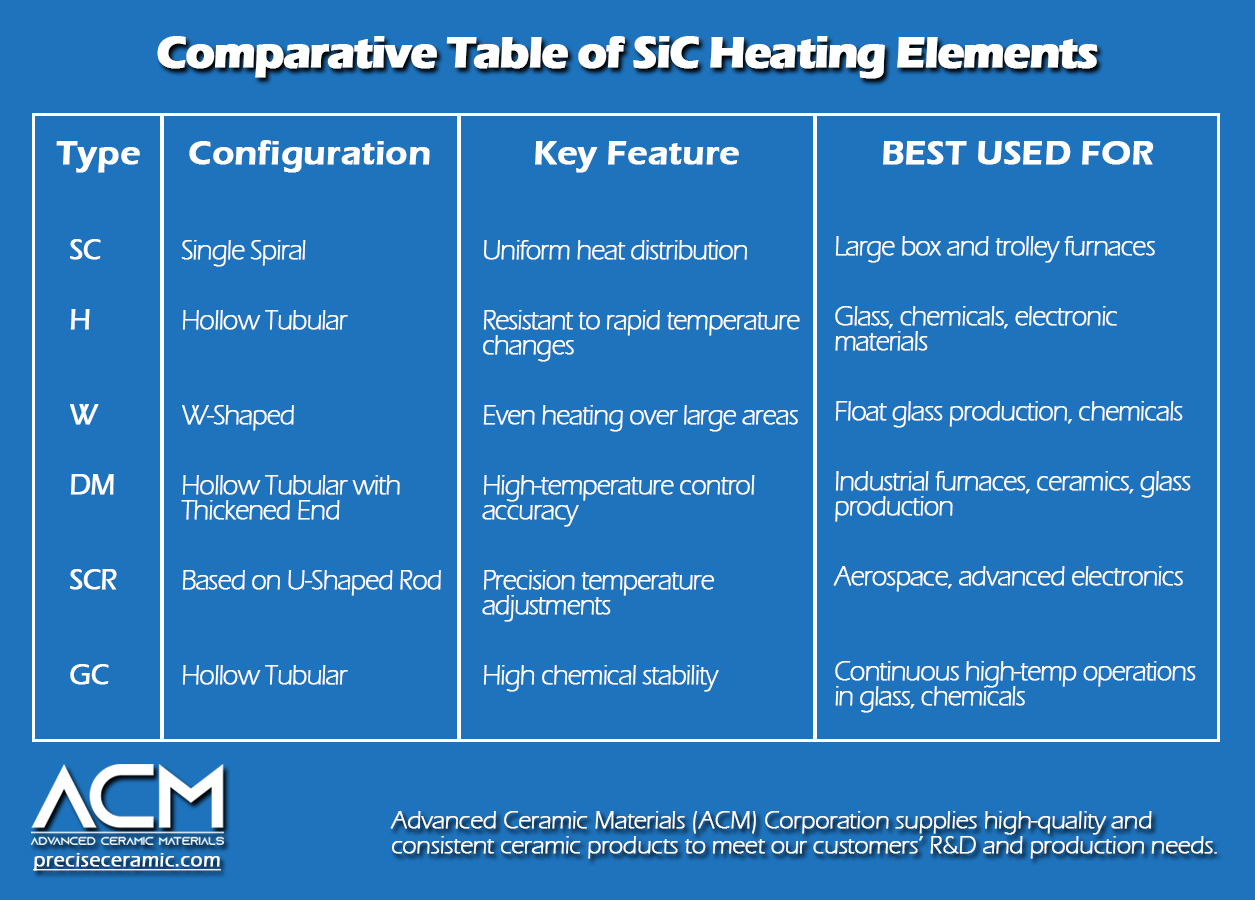

Comparison of Silicon Carbide Heating Element Types

Silicon carbide heating elements vary significantly in design and application, tailored to meet specific industrial needs. The SC Type, with its single spiral configuration, is ideal for applications requiring uniform heating across large areas. In contrast, the H Type and W Type are designed for environments that undergo rapid temperature changes, offering excellent thermal stability and resistance. The DM Type is distinguished by its high-temperature control accuracy, making it suitable for precision applications such as semiconductor manufacturing. The SCR Type leverages advanced thermal management for high-end applications like aerospace, while the GC Type provides robust performance in continuous high-temperature operations, ideal for the chemical and glass industries. Each type's unique properties ensure that they can offer optimal performance in their respective applications, from precise temperature control to enhanced durability under thermal stress.

Table 1. Comparative Table of Silicon Carbide Heating Elements

Conclusion

The diverse array of silicon carbide heating elements, including SC, H, W, DM, SCR, and GC types, cater to a broad spectrum of industrial requirements, each optimized for specific conditions and applications. From achieving uniform heat distribution in large furnaces with the SC Type to maintaining precise temperature control in high-tech manufacturing with the SCR Type, these elements demonstrate exceptional versatility and performance. Advanced Ceramic Materials (ACM) supplies all these types of silicon carbide heating elements, providing high-quality solutions for industries such as metallurgy, ceramics, electronics, and glass production. As technological advancements continue to evolve, we can expect even greater improvements in the efficiency, durability, and environmental sustainability of these critical components, further enhancing their role in modern industrial processes.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments