Why PBN Crucible is Used for Molecular Beam Epitaxy?

It is necessary for the beam source crucible used in molecular beam epitaxy (MBE) to exhibit high-temperature resistance, excellent purity, and long service life. The PBN Crucible satisfies all the aforementioned conditions, hence it serves as a convenient container for evaporating various substances in the molecular beam epitaxy (MBE) process.

What Is Molecular Beam Epitaxy?

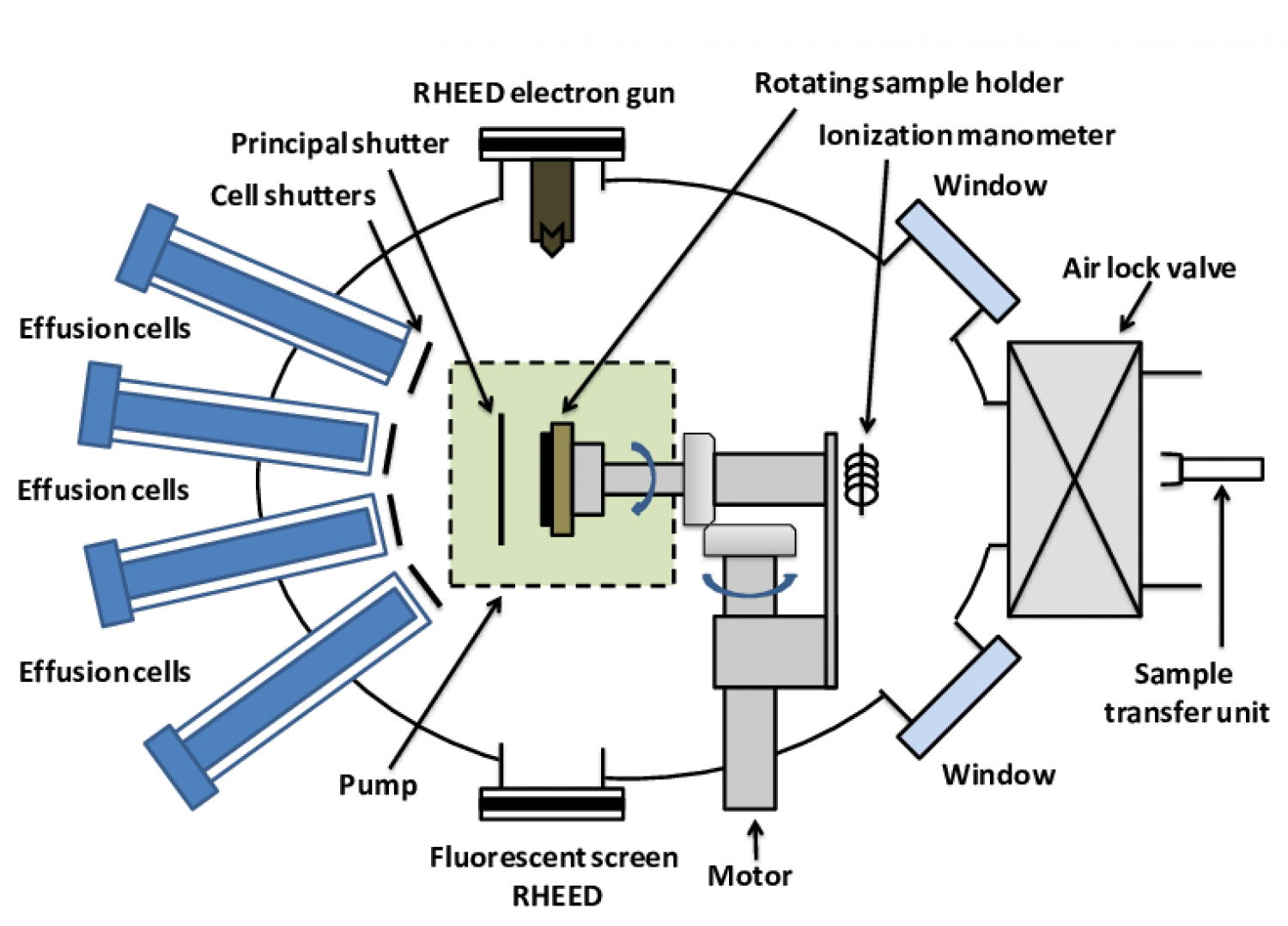

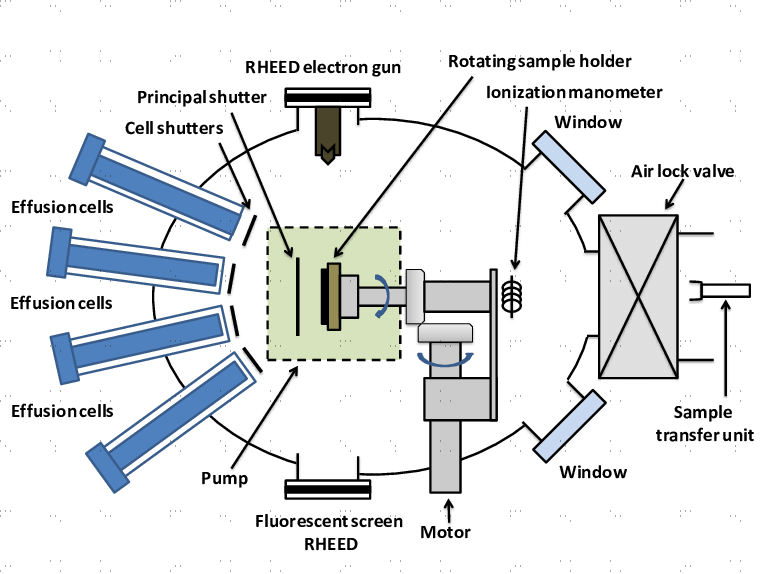

Molecular beam epitaxy (MBE) refers to the process of creating layers on top of a substrate using beams of molecules. Epitaxial simply means "arranged on top of." It is a new approach for producing high-quality crystal thin films on a crystal substrate. One reason why MBE is such an accurate method of crystal growth is that it takes place under extremely controlled circumstances. This includes extreme cleanliness and what is known as an ultra-high vacuum (UHV) - pressures that are as low as one hundred trillionths of atmospheric pressure. These two conditions ensure that no dirt particles or unwelcome gas molecules contaminate the crystal growth. The molecular beam or atomic beam created after collimating via the small hole is immediately sprayed onto the single-crystal substrate at the proper temperature. At the same time, it is also sprayed onto the surrounding single-crystal substrate under ultra-high vacuum conditions. The molecules or atoms can be "grown" layer by layer following the crystal arrangement to produce a thin film on the substrate. This is achieved by guiding the molecular beam to scan the substrate. This approach has been able to create ultra-thin quantum microstructure materials by alternatively developing thin films with distinct components and varying doping, as well as single-crystal thin films that are as thin as tens of atomic layers.

Requirement for MBE-Used Crucible

The operational need guides the standard for a suitable crucible design. The crucible should allow precise temporal control because of the functional requirements for the creation of thin, repeatable layers in the crucible. In terms of repeatability, a mechanical shutter placed close to the crucible serves as the traditional means of starting and stopping the effusion. The temperature of the charge's surface changes when the shutter is opened and closed. This happens as a result of the shutter altering the charge's crucible's radiative shielding. Consequently, when the shutter is opened, the effusion rate is high at first before stabilizing at a reduced amount. As a result, a crucible design goal is to have melt temperatures that are insensitive to changes in radiative shielding at the crucible orifice. These melt temperatures regulate the rate of effusion. Furthermore, given the limited access space in MBE furnaces, MBE-used crucibles should have a substantial melt capacity to lessen the need for frequent recharging. The crucible should produce a beam that is uniform across its cross-section to facilitate the growth of epitaxial layers over the surface of the wafer with a uniform thickness and composition during the effusion process. The crucible designs used today can offer excellent uniformity and huge flux transients or low uniformity and minor flux transients. The source-to-substrate separation and the angular flux distribution at the source both affect how uniformly molecular beam patterns are generated. The emission flux distribution at the cell orifice must be isotropic in the solid angle occupied by the substrate to achieve optimum uniformity.

Schematic of principal elements of molecular beam epitaxy reactor (MBE). Puebla, Jorge. (2012). Spin phenomena in semiconductor quantum dots.

Properties Of PBN Crucibles And How It Is Used In MBE

- The pyrolytic boron nitride (PBN) crucible is well-machinable and has a density of 2.15 to 2.22 g/cm3.

- PBN crucible is popularly known for its non-poisonous nature and Helium can pass through the PBN crucible wall at a rate of 1 10-10 cm/s.

- At room temperature, PBN crucibles do not react with acids, alkalis, salts, or organic reagents. However, they do mildly corrode in molten salt and alkali and do not corrode in various acids when heated. Most molten metals, semiconductors, and related compounds do not react with the PBN crucible. Below 1000 °C, the oxidation resistance is excellent.

- No cracks are seen in the water at 2000 °C thanks to the PBN crucible's exceptional thermal shock resilience.

- The average specific heat of the PBN crucible is first determined, and then the enthalpy value, H, is measured. PBN's dielectric strength was found to be 56000 V/mm at ambient temperature and 22 °C oil immersion.

Pyrolytic boron nitride (PBN) is a special class of ceramic material. They are extensively utilized in the production of single-crystal GaAs VGF, LEC, MBE, Thermal Insulation Board, Synthetic Boats, and PBN-coated products.

Conclusion

One of the most significant II-VI and III-V semiconductor epitaxial growth techniques used today is MBE - a process for building thin films layer by layer in the direction of the material's crystal axis. The PBN crucible is a crucial source furnace container in the MBE process. Thank you for reading our article and we hope it can help you to have a better understanding of PBN heaters. Advanced Ceramic Materials (ACM) supplies high-quality ceramic powder and related products to meet our customers’ R&D and production needs. Please visit https://www.preciseceramic.com/ for more information.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- How PBN Crucibles Ensure the Quality of GaN & SiC Epitaxial Materials

- SiC vs. Quartz Focus Rings: A Cost and Performance Analysis for Advanced Etch

- AlN Ceramic Substrates: Enabling Next-Gen Electrostatic Chucks

- The Amor of Semiconductor Tools: Why High-Purity Al2O3 & AlN Are Preferred for Plasma Process Chambers

- Silicon Carbide - Ultra-High Temperature Ceramics for Extreme Environments