Ceramic Materials for Surgical Devices: Al₂O₃ vs. ZrO₂

Introduction

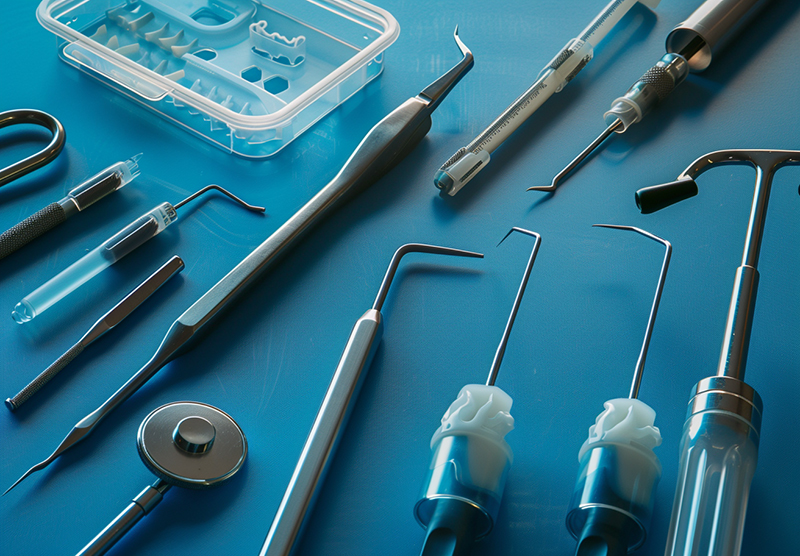

Surgical devices require strong, durable, and safe materials for the human body. As technology advances, ceramic materials have gained popularity in medical applications for their excellent biocompatibility and wear resistance. Among these materials, Al₂O₃ (aluminum oxide) and ZrO₂ (zirconia) are often considered ideal candidates. These ceramics offer different mechanical properties, making them suitable for various surgical tools and implants. In this article, we will explore the characteristics of Al₂O₃ and ZrO₂, compare their performance, and discuss suitable binders for bonding these ceramics onto surgical devices.

Biocompatibility in Surgical Materials

Biocompatibility is essential for any material used in medical devices. It means the material can interact with the body without causing harmful reactions. A biocompatible material should not cause irritation, inflammation, or immune system rejection. For surgical devices, the body’s tissues and fluids come into direct contact with the material, so the material must be safe over long periods. Ceramic materials like Al₂O₃ and ZrO₂ are often chosen for their high biocompatibility. They are chemically stable, non-toxic, and do not react with body fluids, making them ideal for implants and surgical tools.

Overview of Biocompatible Ceramic Materials

Ceramic materials are known for their strength, hardness, and stability. Two of the most commonly used ceramics in surgical devices are Al₂O₃ (aluminum oxide) and ZrO₂ (zirconia). Both offer excellent mechanical properties and biocompatibility, but their characteristics make them suitable for different applications.

Al₂O₃ (Aluminum Oxide)

This material is widely used due to its hardness and wear resistance. It is a relatively low-cost option and easy to process, which makes it ideal for applications such as dental implants, joint replacements, and cutting tools. However, Al₂O₃ is more brittle compared to ZrO₂, and under certain conditions, it may fracture under high stress.

ZrO₂ (Zirconia)

Zirconia is stronger and more fracture-resistant than Al₂O₃. It is often used in high-stress applications, such as artificial joints and dental implants. While it is more expensive and harder to process, its superior toughness makes it a preferred choice for devices that need to withstand greater mechanical forces. Zirconia also has excellent resistance to high temperatures, making it useful for surgical tools that are exposed to heat.

Comparing Al₂O₃ and ZrO₂ for Surgical Devices

When choosing between Al₂O₃ and ZrO₂ for surgical devices, it’s important to consider their mechanical properties, durability, and suitability for different applications.

| Property | Al₂O₃ (Aluminum Oxide) | ZrO₂ (Zirconia) |

| Mechanical Strength | Hard but brittle, fractures under stress | Tougher, more resistant to fractures |

| Wear Resistance | Excellent wear resistance, cost-effective | Excellent wear resistance, higher cost |

| Thermal Stability | Good, but less stable than ZrO₂ | Superior thermal stability, ideal for high-temp tools |

| Cost | Lower cost, easier to process | Higher cost, more difficult to process |

| Applications | Dental implants, cutting tools | Joint replacements, load-bearing implants |

-

Mechanical Strength and Toughness: Zirconia (ZrO₂) is much tougher than aluminum oxide (Al₂O₃). It is more resistant to fractures and cracks, which makes it ideal for high-stress applications, such as joint replacements or load-bearing implants. Aluminum oxide, on the other hand, is hard and wear-resistant but is more brittle and can fracture under sudden force or impact.

-

Wear Resistance: Both materials are highly resistant to wear, making them useful in surgical tools that come into frequent contact with tissues or bones. However, Al₂O₃ tends to be more affordable and easier to manufacture, which can make it a good choice for tools that do not face extreme mechanical stress.

-

Thermal Stability: Zirconia has superior thermal stability compared to aluminum oxide. It can withstand higher temperatures without degrading, which is essential for certain surgical tools exposed to heat during sterilization or use. Aluminum oxide also offers decent thermal resistance but is less effective than zirconia in this regard.

-

Cost and Processing: Al₂O₃ is generally less expensive than ZrO₂ and easier to process. For manufacturers looking for cost-effective solutions in less demanding applications, aluminum oxide may be the better choice. However, for high-performance devices that require enhanced mechanical properties, zirconia’s higher cost may be justified.

While both Al₂O₃ and ZrO₂ offer excellent mechanical properties, their performance in surgical devices also depends heavily on the choice of binder. In many medical applications, ceramic materials need to be bonded to metal or polymer surfaces, ensuring stability and long-term functionality. The right binder not only strengthens the bond between the ceramic and the device but also ensures that the material performs well over time without degrading or causing adverse reactions in the body.

Suitable Binders for Ceramic Materials in Medical Devices

When bonding ceramic materials like Al₂O₃ and ZrO₂ to surgical devices, selecting the right binder is crucial for ensuring durability, biocompatibility, and performance. A binder holds the ceramic particles together and helps attach them securely to the device's surface. The binder must also maintain its integrity in the body’s environment, resisting wear, moisture, and temperature changes.

-

Organic Binders: Epoxies and polyurethanes are commonly used organic binders due to their ease of application and room-temperature processing. These binders form strong bonds with ceramics and are cost-effective. However, organic binders may degrade over time when exposed to body fluids or heat. For short-term applications, they can be effective, but they may not provide the long-term durability needed for permanent implants.

-

Inorganic Binders: Glass-based adhesives or silicates are frequently chosen for their superior chemical resistance and thermal stability. These binders form stronger, more durable bonds with ceramic materials like alumina and zirconia, making them ideal for medical devices exposed to harsh conditions. They are particularly well-suited for long-term use in high-performance implants and surgical tools.

-

Bioactive Binders: Bioactive binders, such as calcium phosphate-based adhesives, are designed to interact with the body's tissues. These binders promote healing and tissue integration, which is essential for applications like orthopedic and dental implants. Their ability to bond with bone tissue makes them particularly valuable for ensuring the long-term success of medical devices.

Choosing the right binder depends on the intended use of the device, the specific ceramic material being bonded, and the conditions it will face inside the body. By carefully considering the mechanical and biocompatibility properties of each.

Conclusion: Selecting the Right Ceramic Material for Surgical Devices

Choosing the right ceramic material and binder for surgical devices is critical to ensuring both their functionality and safety. Al₂O₃ (alumina) and ZrO₂ (zirconia) both offer unique advantages, depending on the specific needs of the medical application. Alumina is ideal for wear-resistant tools that require durability at a lower cost, while zirconia excels in applications demanding higher toughness and fracture resistance.

When considering binders, it is important to select those that will enhance the material's performance in the body. Organic binders can be effective for short-term applications but may not offer the long-term stability needed for permanent implants. Inorganic and bioactive binders, on the other hand, provide greater stability and biocompatibility, making them suitable for high-performance and long-lasting surgical devices.

Advanced Ceramic Materials (ACM) specializes in providing high-quality, biocompatible ceramic options for surgical devices. By leveraging advanced ceramics like alumina and zirconia, ACM offers solutions that meet the mechanical and biological requirements of medical applications. With the right binder and careful consideration of material properties, these ceramics can significantly improve the safety, performance, and longevity of surgical tools and implants.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- Boron Nitride in Cosmetics: Enhancing Performance and Sensory Appeal

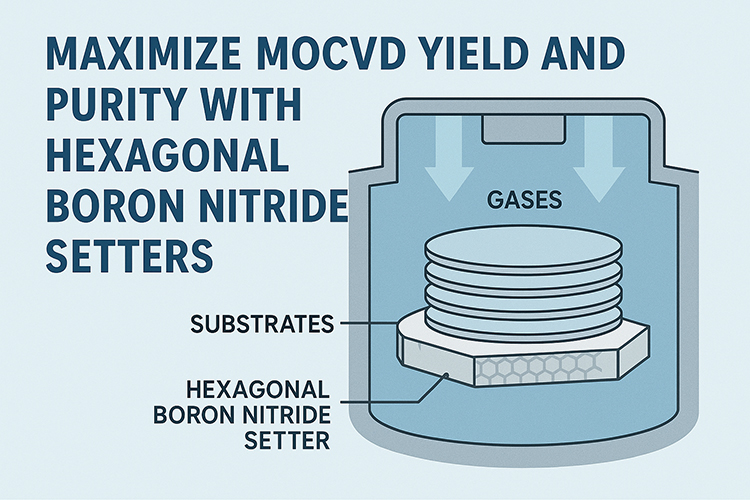

- Maximize MOCVD Yield and Purity with Hexagonal Boron Nitride Setters

- What Are the Advantages and Uses of Boron Nitride Ceramic Sheet?

- The Compression Annealing Advantage for Pyrolytic Boron Nitride

- Beyond Insulation: The Surprising Spectrum of Ceramic Thermal Conductivity