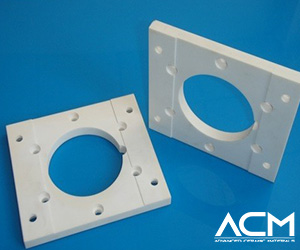

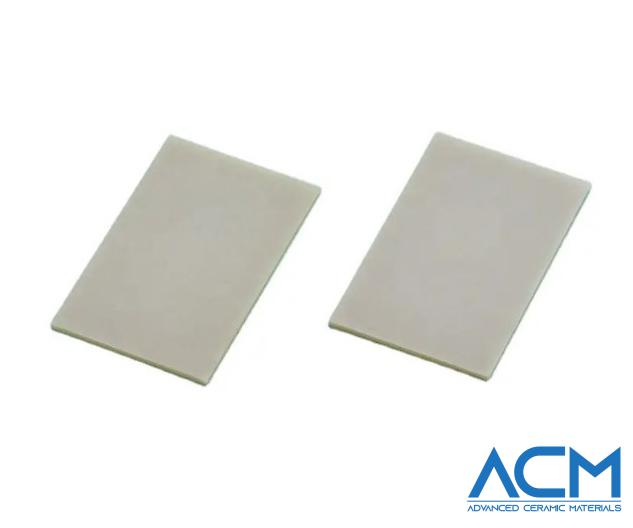

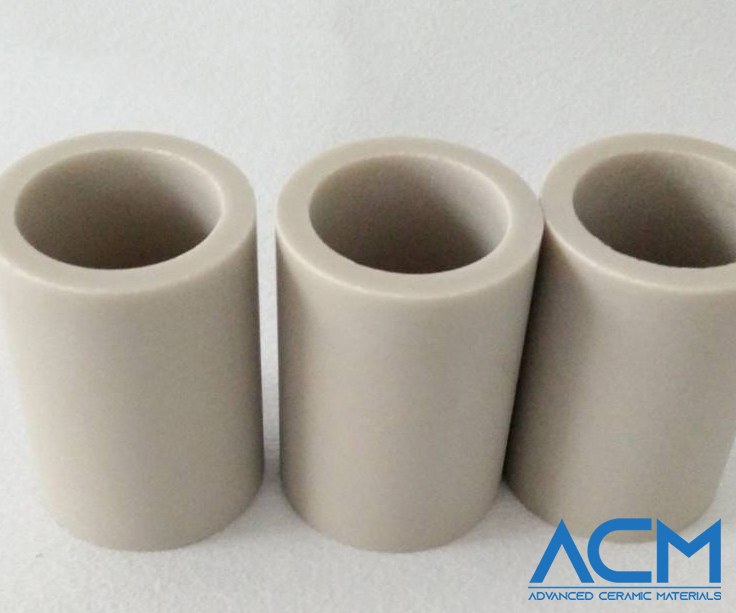

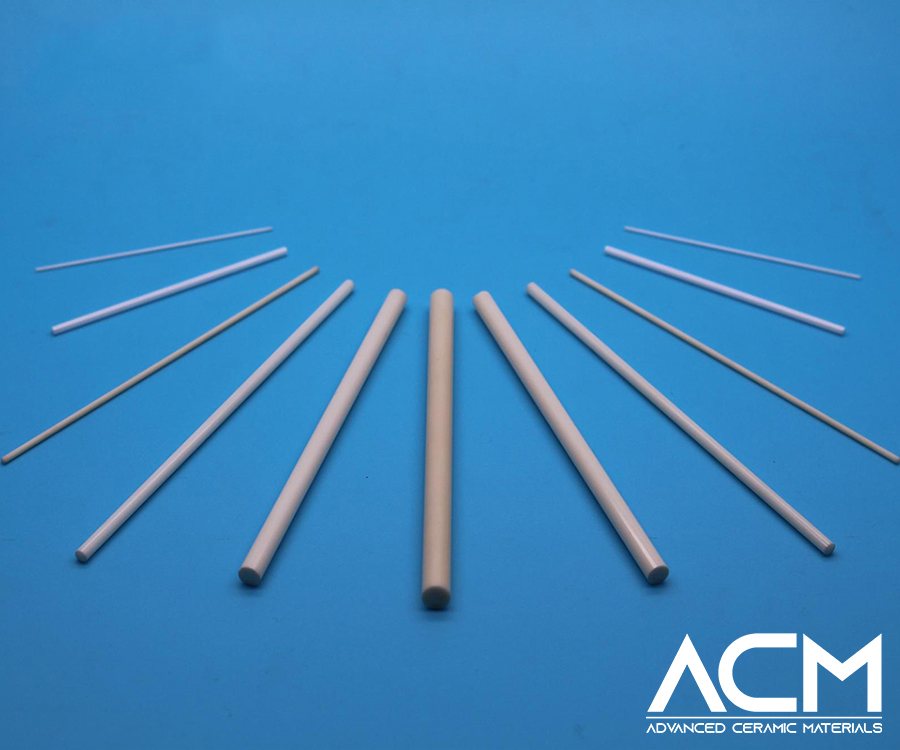

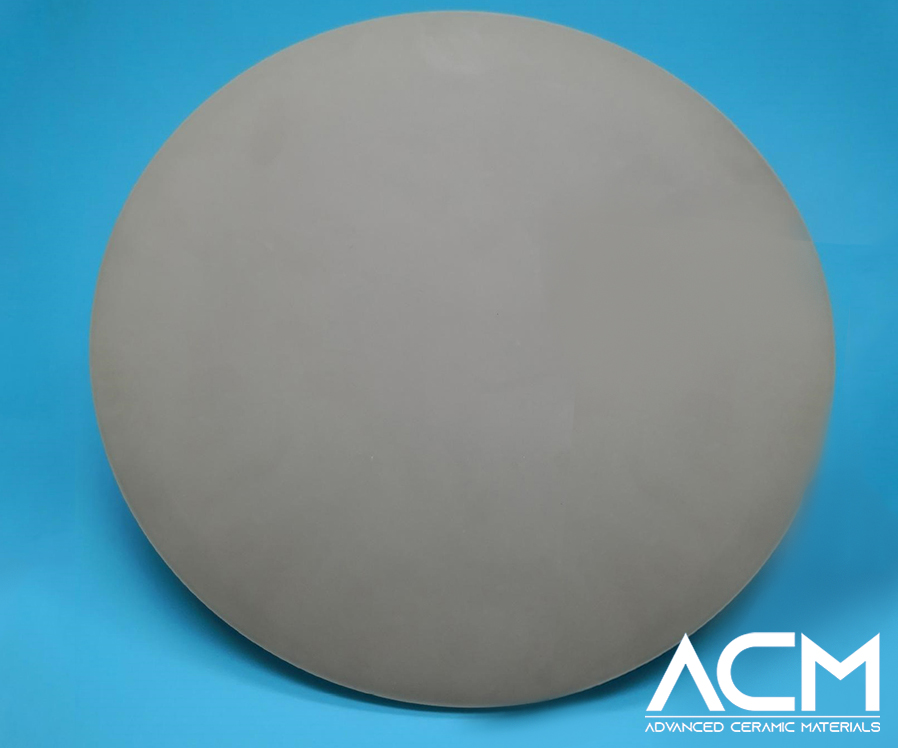

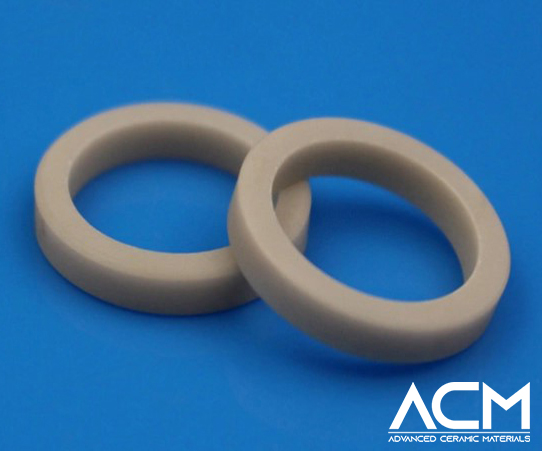

NR2081 Aluminum Nitride Custom Machined Parts

- Catalog No. NR2081

- Material AlN, aluminum nitride

- Purity 99%, 99.7%

- Density 3.26 g/cm3

- Appearance White

- Shape Custom Machined Parts

Datasheet

Inquiry

NR2081 Aluminum Nitride Custom Machined Parts

Aluminum Nitride Custom Machined Parts Description

Alumina nitride custom-machined parts are made of high-purity aluminum nitride ceramics. AlN is a light grey or white ceramic material that has a density of 3.26g/cm3. Due to its high thermal conductivity and great electrical insulation, AlN was used in microelectronic industries. Surface oxidization happened in the air even at room temperature, however, the layer can protect the material up to 1370 C. Metallization methods are available to allow aluminum nitride to be used in electronics applications similar to those of alumina and beryllium oxide.

The hardness of AlN custom machined parts is even higher than alumina, the traditional technical ceramic, making it an ideal material for applications that require good wear resistance.

Aluminum Nitride Custom Machined Parts Specifications

| Aluminum Nitride | |

| Purity | 95.00% |

| Impurities Composition | O 0.9% |

| Fe 0.8% | |

| C 3.25% | |

| N 0.02% | |

| Bulk Density | 3.26 g/cm3 |

| Heat Conductivity | 140-200 W/MK |

| Dielectric Constant | 8-9 1 MHZ.25°C |

| Coefficient Thermal Expansion | 4.5 10^-6/K |

| Flexural Strength | 280-380 Mpa |

| Compressive Strength | 300-310 Mpa |

Aluminum Nitride Custom Machined Parts Advantages

AlN custom machined parts have the following advantages:

* Very high thermal conductivity (> 170 W/mK)

* High electrical insulation capacity (>1.1012Ωcm)

* Strength according to the double ring method >320 MPa (biaxial strength)

* Low thermal expansion 4 to 6×10-6K-1(between 20 and 1000°C)

* Good metallization capacity

Aluminum Nitride Custom Machined Parts Applications

Aluminum nitride custom-machined parts are used in the following applications:

* Opto-electronics;

* Dielectric layers in optical storage media;

* Electronic substrates, chip carriers where high thermal conductivity is essential;

* Military applications.

Request a Quote

-

Attachment (Optional)

No file chosen