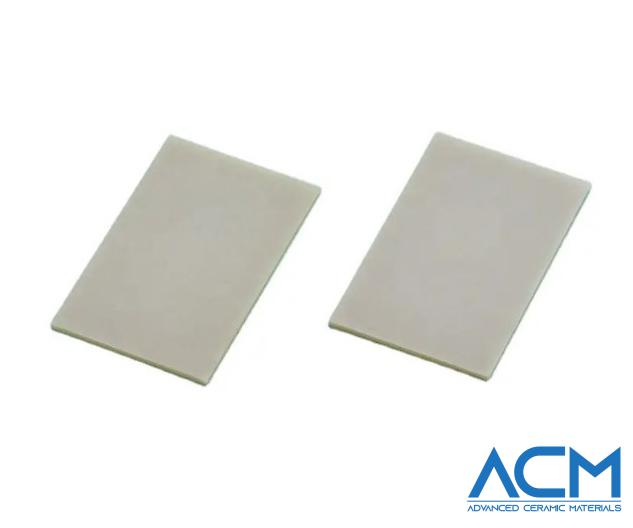

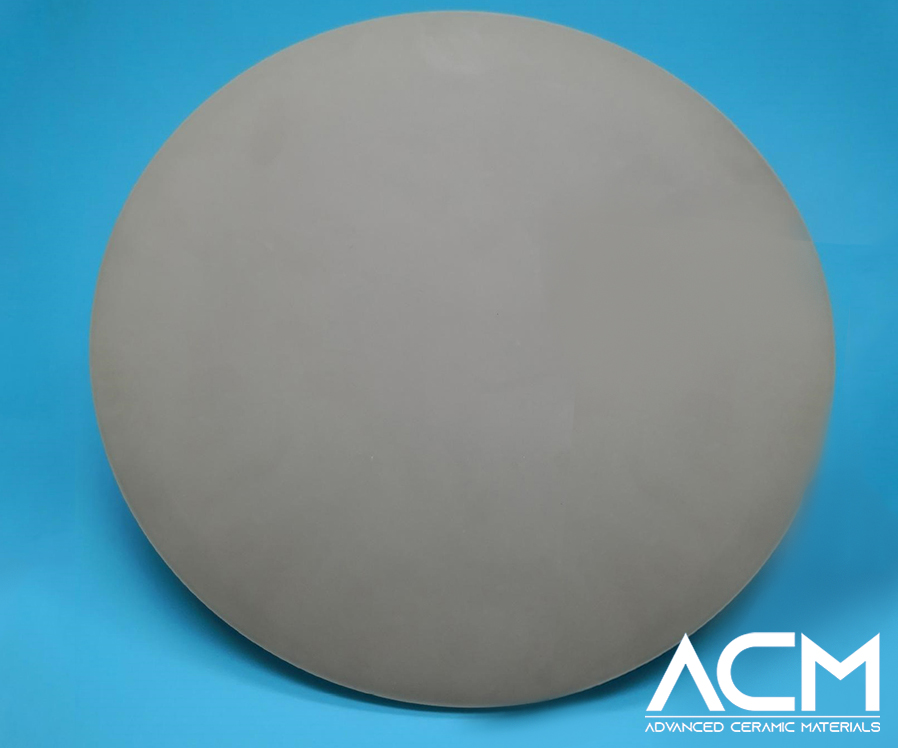

NR0916 Aluminum Nitride Substrates, AlN Substrates

- Catalog No. NR0916

- Material AlN, aluminum nitride

- Purity 99%, 99.7%

- Density 3.26 g/cm3

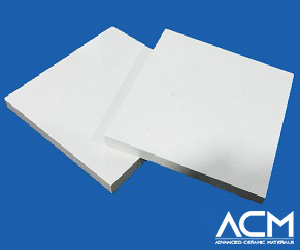

- Appearance White

- Shape Sheet

Datasheet

Inquiry

NR0916 Aluminum Nitride Substrates, AlN Substrates

Description

Advanced Ceramic Materials (ACM) offers high-purity Aluminum Nitride (AlN) Substrates, a superior ceramic material known for its excellent thermal conductivity, high electrical insulation, and low thermal expansion. AlN substrates are widely used in the microelectronics industry due to their ability to withstand high temperatures and their superior mechanical properties. The protective aluminum oxide layer that forms on the surface enhances durability, allowing use up to 1370°C.

Key Features and Benefits

- High Thermal Conductivity: Greater than 170 W/mK, ideal for heat dissipation.

- High Electrical Insulation: Superior dielectric strength, >1.10^12Ωcm.

- Mechanical Strength: Biaxial strength >320 MPa ensures durability.

- Low Thermal Expansion: Coefficient of 4 to 6 x 10^-6/K between 20 and 1000°C.

- Good Metallization Capacity: Suitable for various electronics applications.

- Non-Toxic: Safe alternative to BeO.

Specifications

| Property | Value |

|---|---|

| Material | AlN (Aluminum Nitride) |

| Purity | 99%, 99.7% |

| Density | 3.26 g/cm³ |

| Appearance | White |

| Shape | Sheet |

| Melting Point | 2973 °C |

| Thermal Conductivity | >170 W/mK |

| Electrical Insulation | >1.10^12Ωcm |

| Biaxial Strength | >320 MPa |

| Thermal Expansion Coefficient | 4 to 6 x 10^-6/K (20 to 1000°C) |

Technical Data

| Property | Value |

|---|---|

| Flexural Strength | 450 MPa |

| Vickers Hardness | 11 GPa |

| Fracture Toughness | 3.0 MPa/m |

| Dielectric Constant (1 MHz) | 8.5 |

| Dielectric Loss Factor (1 MHz) | 0.3 x 10^-3 |

| Volume Resistivity (25°C) | >10^14 Ωcm |

| Breakdown Strength (DC) | >15 kV/mm |

Applications

AlN substrates are used in a wide range of applications:

- Opto-Electronics: Ideal for optical storage media dielectric layers.

- Electronic Substrates: Essential for chip carriers and other components requiring high thermal conductivity.

- Military Applications: Suitable for use in high-stress environments due to robust thermal and mechanical properties.

- LED Packages: High thermal conductivity is crucial for LED performance.

- Power Electronics: Used in power modules for efficient heat dissipation.

Packaging and Quality Assurance

Our aluminum nitride substrates are carefully handled to prevent damage during storage and transportation, ensuring they remain in their original high-quality condition.

Frequently Asked Questions (FAQs)

-

What is the maximum operating temperature for AlN substrates?

- Our AlN substrates can withstand temperatures up to 1370°C.

-

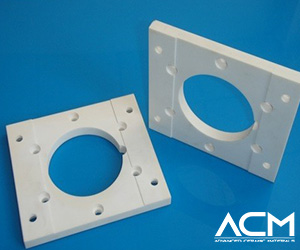

Do you offer custom sizes and shapes?

- Yes, we offer custom sizes and shapes to meet specific requirements. Please contact us for more details.

-

What are the typical applications for AlN substrates?

- AlN substrates are used in opto-electronics, electronic substrates, military applications, LED packages, and power electronics.

Discover More

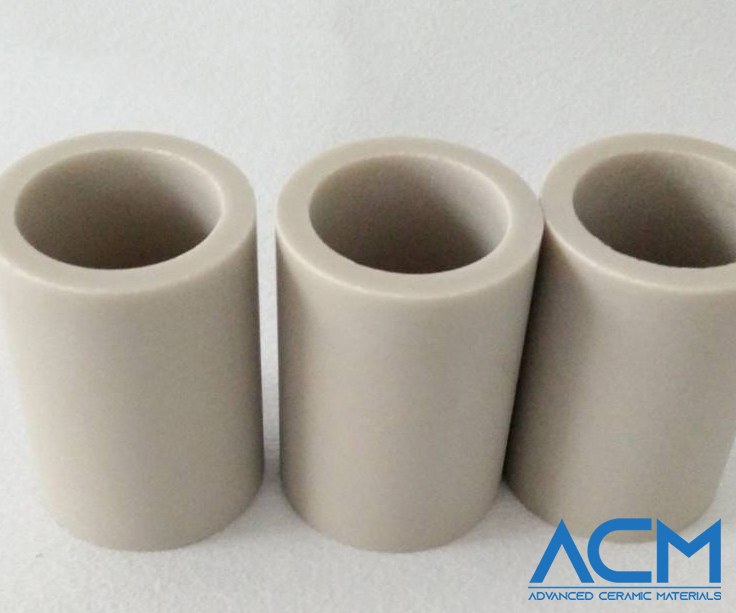

- Other AlN Products: Explore our range of aluminum nitride products.

- Latest Post: Read our latest article on Aluminum Nitride Substrate Applications.

- Contact Us: Get in touch or request a quote for more information.

Request a Quote

-

Attachment (Optional)

No file chosen