Aluminum Nitride (AlN)

Aluminum nitride (AlN) is recognized for its hexagonal wurtzite structure and refractory properties, exhibiting a distinct blue-white color in its purest form, though typically appearing as gray or white in ceramic applications. Renowned for its high temperature stability in inert atmospheres, AlN can withstand temperatures up to 2800 °C. It combines excellent thermal conductivity with superior electrical insulation, alongside a low dielectric constant and minimal dielectric loss. These features make aluminum nitride a crucial component in developing technologies across optics, electronics, and renewable energy sectors, enabling advancements in high-performance applications where material stability and efficiency are paramount.

The material properties of AlN further include an impressive thermal conductivity exceeding 170 W/mK, and a high electrical insulation capacity beyond 1.1012Ωcm, with biaxial strength over 320 MPa. Its thermal expansion coefficient remains low (4 to 6×10-6K-1 between 20 and 1000°C), ensuring dimensional stability across a broad temperature range. Moreover, AlN's compatibility with metallization processes enhances its utility in complex electronic systems and components. This combination of properties positions aluminum nitride as an indispensable material in the engineering of innovative devices, contributing significantly to advancements in technology and industry.

More Info About Aluminum Nitride

Products | Structure | Specification | Applications | Video | FAQs | Safety Data Sheet

Aluminum Nitride Structure

Aluminum Nitride (AlN) is distinguished by its hexagonal wurtzite crystal structure, which forms the basis of its unique properties. This structure facilitates covalent bonding between aluminum and nitrogen atoms, leading to a material that is both robust and capable of withstanding high temperatures. The preparation of AlN involves several sophisticated methods, each contributing to the purity and specific properties of the final product. Techniques such as direct nitridation, where aluminum is reacted with nitrogen gas, and carbothermal reduction, involving the reaction of alumina with carbon in a nitrogen atmosphere, are commonly employed. Additionally, high-energy ball milling, which mechanically alloys the material to fine powders, and high-temperature self-propagating synthesis, a method that utilizes exothermic reactions to achieve sintering, play crucial roles in the production of high-quality aluminum nitride.

Solid State, Public domain, via Wikimedia Commons

Moreover, chemical vapor deposition (CVD) is another pivotal method for creating AlN films, offering precise control over the material's thickness and composition. This variety of synthesis techniques allows for the tailoring of AlN's properties to specific applications, enhancing its suitability for a broad range of technological uses. The meticulous control over the aluminum nitride structure not only optimizes its thermal and electrical performance but also enhances its integration into complex systems. As a result, AlN's structure, characterized by its covalent bonds and hexagonal lattice, is central to its application in electronics, optics, and high-temperature environments, where its exceptional properties can be fully leveraged.

Aluminum Nitride Specification

| Property | Specification |

|---|---|

| Crystal Structure | Hexagonal Wurtzite |

| Color | Typically gray or white; pure form can appear blue-white |

| Melting Point | Approximately 2800 °C |

| Thermal Conductivity | > 170 W/mK |

| Electrical Insulation | > 1.1012 Ωcm |

| Biaxial Strength | > 320 MPa |

| Thermal Expansion (20-1000°C) | 4 to 6 × 10-6 K-1 |

| Density | ~3.26 g/cm³ |

| Dielectric Constant | ~8.6 at 1 MHz |

| Dielectric Loss (tan δ) | ~0.0007 at 1 MHz |

| Band Gap | ~6.2 eV |

| Chemical Stability | Stable in inert atmospheres |

Aluminum Nitride Applications

Aluminum Nitride (AlN) is a versatile ceramic material with applications spanning various high-tech industries due to its exceptional thermal conductivity, electrical insulation properties, and chemical stability. Here’s a detailed look into its key applications:

Electronics and Semiconductors

AlN is widely used as a substrate material in electronic applications due to its excellent thermal management properties. It effectively dissipates heat in high-power semiconductor devices, such as transistors and integrated circuits, enhancing their performance and longevity. Additionally, its high electrical insulation capability makes it suitable for electronic packaging and insulation layers in microelectronic devices.

LED Technology

In the realm of optoelectronics, aluminum nitride serves as a crucial substrate for gallium nitride (GaN) based LEDs. Its compatibility with GaN, coupled with superior thermal conductivity, supports the development of high-efficiency LEDs, including ultraviolet (UV) LEDs used in sterilization, water purification, and medical diagnostic applications.

Thermal Management Solutions

Due to its high thermal conductivity, AlN is employed in heat sinks, heat spreaders, and cooling systems in various electronic devices, including CPUs, lasers, and power electronics. It plays a vital role in managing the thermal loads, ensuring devices operate within their optimal temperature ranges.

RF and Microwave Components

AlN's low dielectric constant and loss tangent make it an excellent material for radio frequency (RF) and microwave components, such as isolators, circulators, and antennas. These properties minimize signal loss and improve the efficiency of communication systems.

Aerospace

In aerospace, AlN's ability to withstand extreme temperatures and its low thermal expansion coefficient are exploited in components exposed to high thermal stresses, such as sensors, electronic warfare systems, and components within jet engines.

Industrial Applications

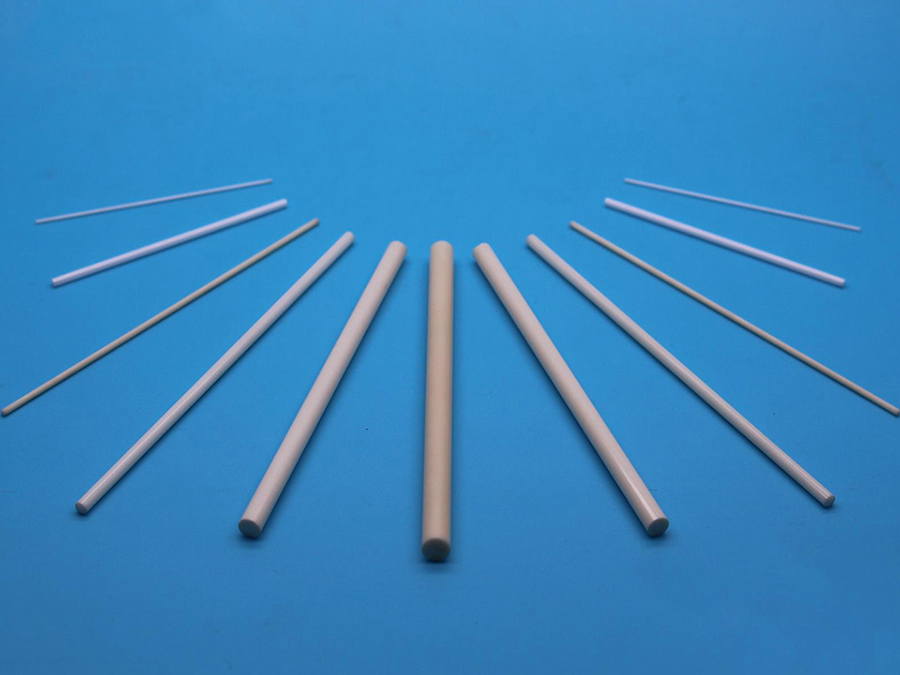

AlN ceramics are used in industrial applications requiring high temperature resistance and durability, including crucibles for molten metal processing, thermocouple sheaths, and components in semiconductor manufacturing equipment.

Automotive

Within the automotive sector, aluminum nitride is finding increasing use in sensors and electronic components that require efficient heat dissipation to withstand the demanding conditions of automotive environments, contributing to the enhancement of vehicle performance and safety features.

ACM Ceramic Product Video

Your AlN Ceramics Supplier

Advanced Ceramic Materials is a leading supplier of aluminum nitride ceramic products of the highest quality for a wide range of applications. We are happy to provide advice on materials, design, and application. Feel free to contact us with any questions about AlN or other ceramic materials that are not listed on the website.

Read more: What is Aluminum Nitride Ceramic?

| Chemical Formula | AlN |

| Mechanical | |

| Density | 3.3 g/cm3 |

| Hardness | 10.4 GPa |

| Modulus of Elasticity | 320 GPa |

| Flexural Strength | 382 MPa |

| Compressive Strength | 1.5 GPa |

| Poisson's Ratio | 0.21 |

| Fracture Toughness | 2-3 MPa m½ |

| Electrical | |

| Dielectric Strength | 15 ac V/mm |

| Dielectric Constant | 8.56 (@ 1 MHz) |

| Volume Resistivity | 1.4*10^14 ohm-cm |

| Thermal | |

| Coefficient of Thermal Expansion | 4*10-6 x 10^-6/°C |

| Thermal Conductivity | 170 W/(m*K) |

| Specific Heat | 0.72 x10^3 J/(Kg*K) |

| Shock Resistance | - |

| Maximum Working Temperature | 900 °C |