MG4431 Dense Magnesium Oxide Ceramics

- Catalog No. MG4431

- Material MgO

- Content >99.0%

- Bulk Density 3.44 g/cm3

Datasheet

Inquiry

MG4431 Dense Magnesium Oxide Ceramics

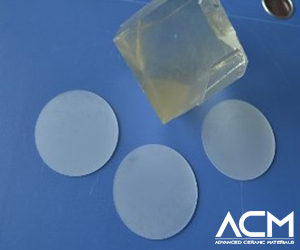

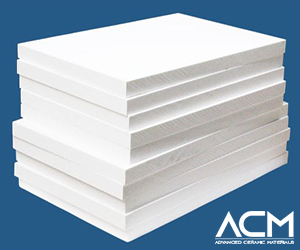

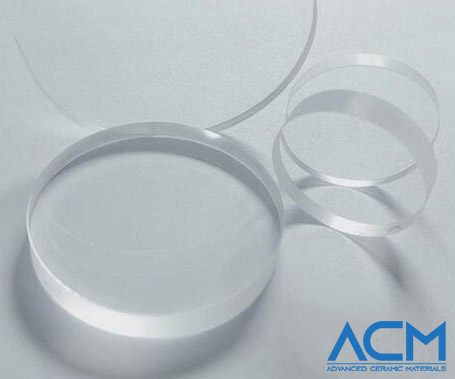

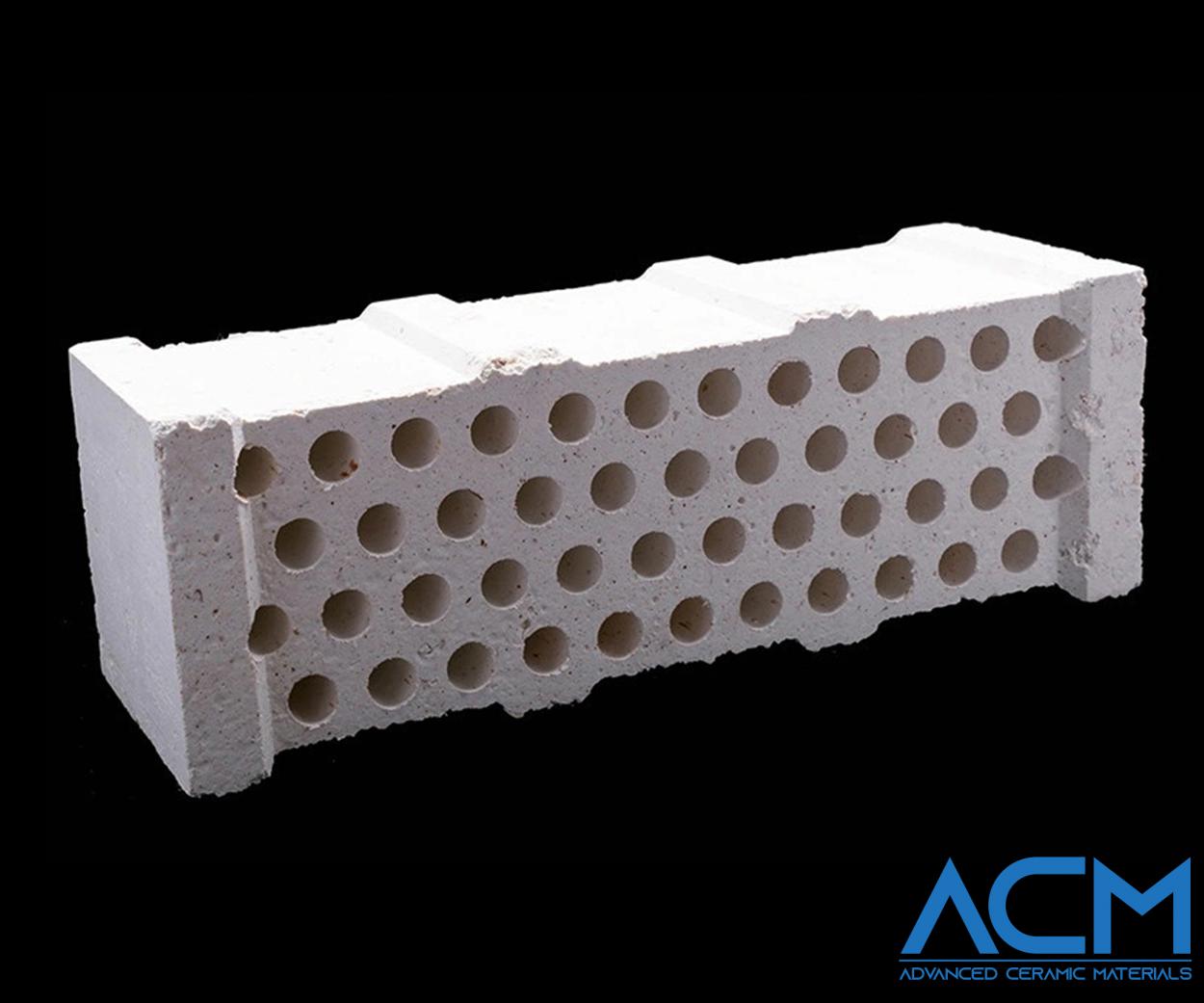

Dense Magnesium Oxide Ceramics Description

Dense Magnesium Oxide Ceramics are used as a refractory under severe conditions because their melting point (3098K) is the highest in the oxide. Magnesium Oxide is superior in corrosion resistance in molten metal. Magnesium Oxide Ceramics can be used for a lot of metals compared with Aluminum Oxide Ceramics.

Dense Magnesium Oxide Ceramics Specifications

Chemical Composition (%)

| MgO | 96.5 |

| CaO | 0.50 |

| SiO2 | 0.10 |

| Al2O3 | 0.55 |

| Fe2O3 | 0.06 |

| B2O3 | 0.002 |

| Y2O3 | 2.00 |

Physical Properties

| Category | Value |

| Bulk density (g/cm3) | 3.44 |

| Apparent porosity (%) | 0.10 |

| Water absorption (%) | 0.03 |

| Three point bending strength (MPa) | 123 |

| Thermal expansion coefficient (10-6·K-1) | 13.9 |

| Thermal conductivity (W·m-1·K-1) | 46.3 |

| Specific heat (J·kg-1·K-1) | 990 |

Dense Magnesium Oxide Ceramics Application

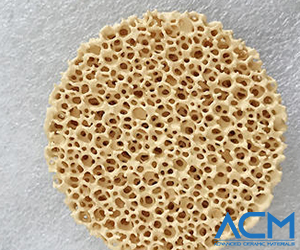

Dense Magnesium Oxide Ceramics can be used to manufacture crucibles for metal melting and tools for Sintering Ceramics. They can be used for heat treatment of nickel alloys, plutonium/uranium refining, superconductor materials, piezoelectric materials, and lead materials.

Dense Magnesium Oxide Ceramics Packaging

Our Dense Magnesium Oxide Ceramics are carefully handled during storage and transportation to preserve the quality of our product in its original condition.

Request a Quote

-

Attachment (Optional)

No file chosen