Magnesium Oxide Ceramic, MgO

Magnesium oxide is an inorganic oxide of magnesium, and its chemical formula is MgO. It is a white solid at room temperature. Magnesium oxide exists in nature in the form of periclase and is the raw material for magnesium smelting.

Magnesium oxide has high fire resistance and insulation properties. It can be transformed into crystal after high temperature burning above 1000℃, and it will become dead burnt magnesia (magnesia) or sintered magnesia when it rises to 1500-2000°C.

Read more: Magnesium Oxide Ceramic Materials – An Overview

Magnesium Oxide Properties:

- Good refractoriness

- Good corrosion resistance

- High thermal conductivity

- Low electrical conductivity

- Transparency to infrared

Magnesium Oxide Specification

| Fused Magnesite MgO | |||

| Item No. | Description | Purity | Lot Size |

| OX12F-98 | fused magnesite 0-10 mm, 0-15mm, 0-30mm, or 0-90mm |

98 % | 1 MT 10 MT Customize |

| OX12F-97 | fused magnesite 0-10 mm, 0-15mm, 0-30mm, or 0-90mm |

97% | 1 MT 10 MT Customize |

| OX12F-96 | fused magnesite 0-10 mm, 0-15mm, 0-30mm, or 0-90mm |

96% | 1 MT 10 MT Customize |

Magnesium Oxide Different Types

Magnesium Oxide is divided into two types: light magnesium oxide and heavy magnesium oxide.

Light Magnesium Oxide is loose in volume, white amorphous powder, odorless, tasteless, and non-toxic, with a density of 3.58g/cm3. It is hardly soluble in pure water and organic solvents, and its solubility in water increases due to the presence of carbon dioxide. It can be dissolved in an acid and ammonium salt solution. It is converted into crystals after high-temperature burning. In the case of carbon dioxide in the air, magnesium carbonate double salt is formed.

Heavy Magnesium Oxide is compact in size and is a white or beige powder. It is easy to combine with water, and it is easy to absorb moisture and carbon dioxide in the exposed air. It is easy to gel and harden when mixed with a magnesium chloride solution.

Magnesium Oxide Applications

- Used to determine sulfur and pyrite in coal and sulfur and arsenic in steel.

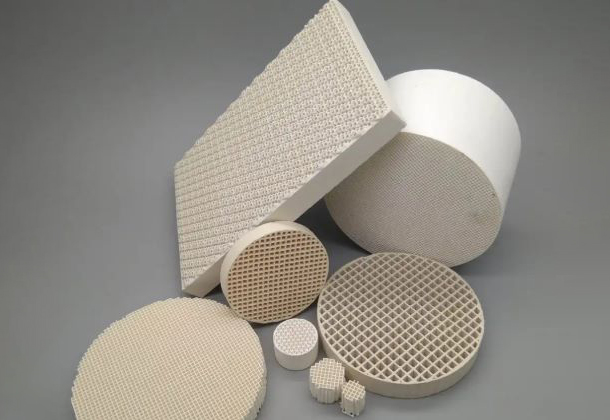

- Used as a raw material for preparing ceramics, enamels, refractory crucibles, and refractory bricks.

- Used as a polishing agent, adhesive, paint, and paper filler, and as an accelerator and activator for neoprene and fluorine rubber.

- Used as a catalyst and raw material for the manufacture of magnesium salts.

- Used in the manufacture of glass, dyed meal, phenolic plastic, etc.

- Used in the manufacture of artificial chemical floors, artificial marble heat-proof boards, sound-proof boards, and plastic industry as a filler.

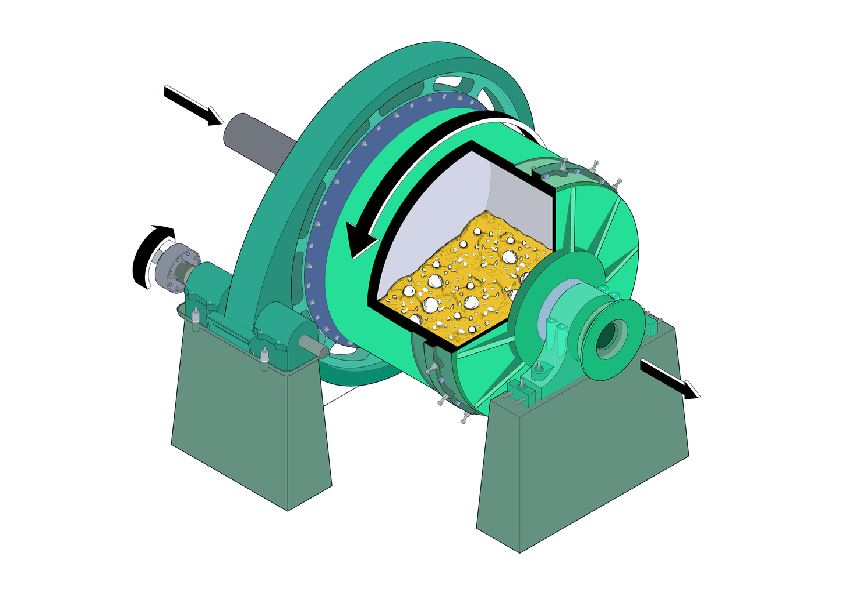

ACM Ceramic Product Video

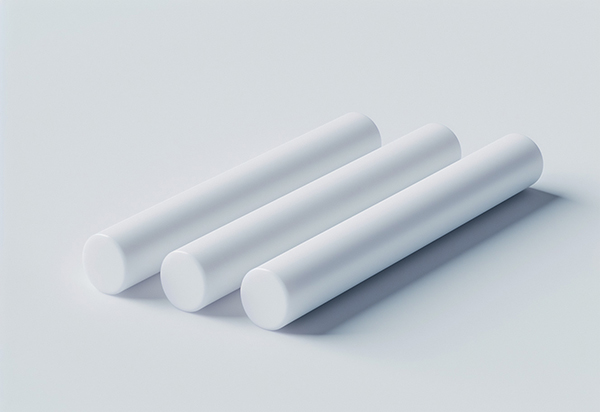

Your Magnesium Oxide Ceramics Supplier

Advanced Ceramic Materials is a leading supplier of magnesium oxide ceramic products of the highest quality for a wide range of applications. We are happy to provide advice on materials, design, and application. Feel free to contact us for any questions about magnesium oxide or other ceramic materials that are not listed on the website.

| Chemical Formula | MgO |

| Mechanical | |

| Density | 2.2-2.5 g/cm3 |

| Hardness | 7.7 GPa |

| Modulus of Elasticity | 280 GPa |

| Flexural Strength | 150 MPa |

| Compressive Strength | 170 MPa |

| Poisson's Ratio | 0.17 |

| Fracture Toughness | 2-3 MPa m½ |

| Electrical | |

| Dielectric Strength | 15-20 kV/mm |

| Dielectric Constant | 9.8 (@ 1 MHz) |

| Volume Resistivity | >1014 ohm·cm |

| Thermal | |

| Coefficient of Thermal Expansion | 1.3 x 10^-5/°C |

| Thermal Conductivity | 46.3 W/(m*K) |

| Specific Heat | 990 J/(Kg*K) |

| Shock Resistance | - |

| Maximum Working Temperature | 2240 °C |