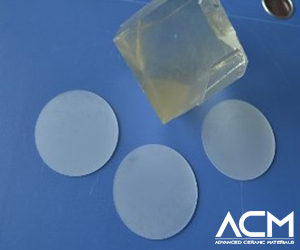

MG1755 Magnesium Oxide Wafer

- Catalog No. MG1755

- Material MgO

- Clear Aperture >95 %

- Dimension tolerance ±0.05 mm

Datasheet

Inquiry

MG1755 Magnesium Oxide Wafer

Magnesium Oxide Wafer Description

Magnesia Ceramic is a ceramic material consisting of at least 90% of Magnesium Oxide(MgO). It demonstrates good mechanical strength and operates well when uniformly heated or cooled and thermal shock is avoided. It offers superior performance to Alumina, being stable to 2200°C.

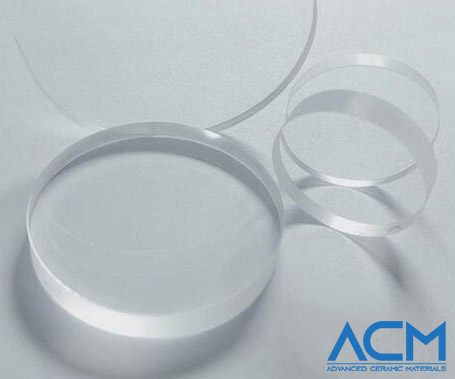

MgO wafer can be fabricated in a round or square shape, with a SEMI flat or without flat, one side polished or two sides polished sizes from 10 x10 mm to 2 ", thickness range from 0.4, 0.5, 1 to 2 mm, surface are epi polished with low surface roughness. We have twin-free and defect-free MgO substrate with various orientations, and, and a high-precision surface finish.

Magnesium Oxide Wafer Specifications

| Materials | MgO |

| Orientation |

<100> / <111> / <110> or others |

| Parallel | 10" |

| Perpendicular | 5' |

| Surface quality | 10/5 |

| Wavefront Distortion | λ/4@632 nm |

| Surface flatness | λ/8@632 nm |

| Clear Aperture | >95 % |

| Chamfer | <0.1×45° |

| Thickness/Diameter Tolerance | ±0.05 mm |

| Maximum dimensions | dia 50×100 mm |

Magnesium Oxide Wafer Applications

Magnesium Oxide Wafer is widely used in the production of ferroelectric films, magnetic films, light spot films, and high-temperature superconducting films. It can be used to make high-temperature superconducting microwave filters and other devices required by mobile communication equipment.

Packaging

Our Magnesium Oxide Wafer is carefully handled during storage and transportation to preserve the quality of our product in its original condition.

?

Request a Quote

-

Attachment (Optional)

No file chosen