Ceramic Substrates Replacing Metals in 3C Electronics: Applications and Advantages

1. Introduction

The 3C electronics industry, encompassing Consumer Electronics, Computers, and Communication Devices, represents one of the fastest-growing and most innovative sectors globally. As devices become more compact, efficient, and multifunctional, the materials used in their manufacturing face increasing demands. Substrates, which provide structural support and are key components in electronic circuits, are critical to these advancements.

Traditionally, metal substrates have been widely used in 3C electronics due to their strength and conductivity. However, as technology evolves, challenges such as inefficient heat dissipation, susceptibility to corrosion, and the weight of metal substrates have emerged. These drawbacks limit the performance and durability of modern electronic devices.

In response, ceramic substrates have gained significant attention. With exceptional thermal, mechanical, and chemical properties, ceramic substrates are emerging as a superior alternative to metals in various 3C applications. Their ability to address the challenges of heat management, weight reduction, and environmental resistance makes them a transformative innovation in the industry.

2. Core Properties of Ceramic Substrates

Physical Properties

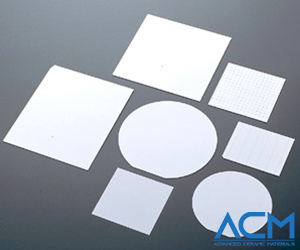

Ceramic substrates are prized for their lightweight yet robust nature, offering a significant reduction in the overall weight of electronic devices. This is especially beneficial for portable devices such as smartphones and laptops. Additionally, their superior thermal conductivity allows for efficient heat dissipation, ensuring stable performance even in high-power applications.

Chemical Properties

Unlike metals, ceramic materials are highly resistant to corrosion and oxidation. This makes ceramic substrates ideal for environments with high humidity or extreme temperatures. Furthermore, their excellent electrical insulation properties prevent electrical interference, enhancing the reliability of electronic components.

Mechanical Properties

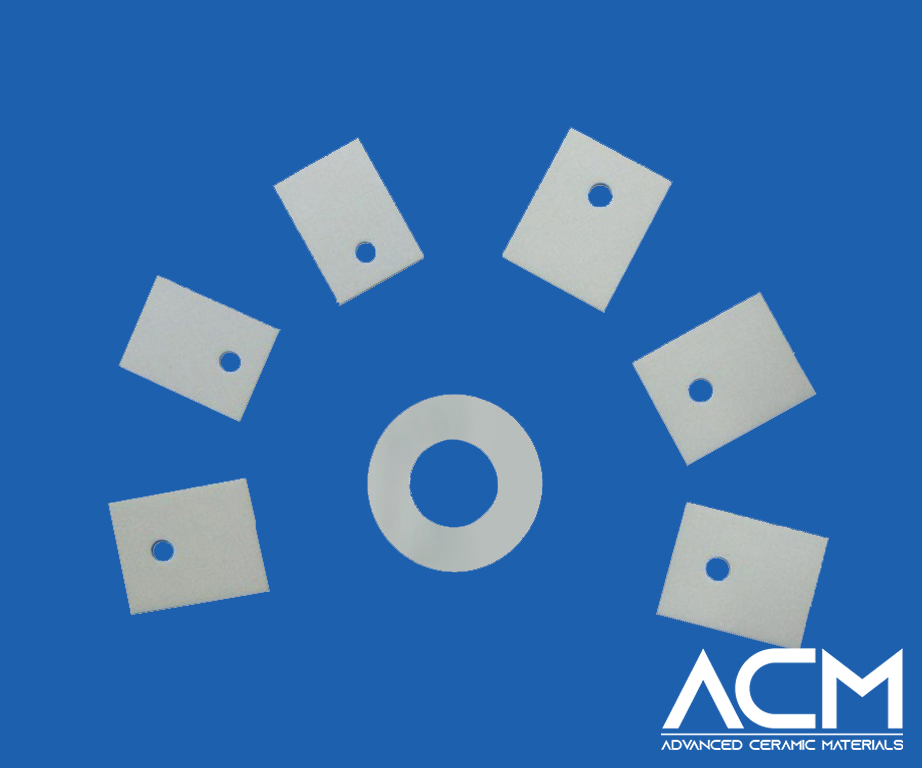

Ceramic substrates demonstrate exceptional durability, withstanding high mechanical stress and temperature variations. Their high wear resistance ensures long-lasting performance, making them suitable for demanding applications such as 5G communication equipment and high-performance computing.

3. Applications of Ceramic Substrates in 3C Electronics

1) Consumer Electronics

Smartphones increasingly use ceramic substrates to improve thermal management and reduce device thickness. For instance, ceramic casings dissipate heat efficiently and enhance premium models' aesthetic appeal. Similarly, wearable devices benefit from the lightweight and durable nature of ceramics, ensuring comfort and reliability for users.

2) Computer Devices

In high-performance computing systems, ceramic substrates enable better heat dissipation for processors and graphic cards, ensuring uninterrupted performance. Portable devices like laptops and tablets leverage ceramic components to balance durability and portability.

3) Communication Devices

With the rise of 5G networks, ceramic substrates have become integral to base station modules, antennas, and power amplifiers. Their superior thermal and electrical properties make them an ideal choice for handling the high-frequency signals and power requirements of modern communication systems.

4. Advantages of Ceramic Substrates Over Metal Substrates

Performance Improvements

Ceramic substrates outperform metal alternatives in thermal management, ensuring efficient heat dissipation and reducing the risk of overheating. Their superior electrical insulation makes them suitable for high-frequency communication applications, providing stable and reliable performance.

Environmental Adaptability

Ceramics excel in harsh environments, withstanding high temperatures, humidity, and corrosive conditions. This adaptability extends the lifespan of electronic components, reducing maintenance and replacement costs.

Sustainability Benefits

The lightweight nature of ceramic substrates contributes to the overall reduction in device weight, enhancing portability. Additionally, ceramic materials align with the industry’s shift toward green manufacturing practices, offering a more sustainable alternative to traditional metals.

5. Technology and Market Trends

Technological Developments

Advancements in ceramic substrate manufacturing techniques, such as Low-Temperature Co-fired Ceramics (LTCC) and High-Temperature Co-fired Ceramics (HTCC), are enabling greater precision and cost efficiency. Research into new materials like alumina, aluminum nitride, and silicon nitride further expands the potential applications of ceramic substrates in 3C electronics.

Market Trends

The global ceramic substrate market is experiencing rapid growth, driven by the rising demand for compact, energy-efficient electronic devices. As 5G technology and IoT applications proliferate, the adoption of ceramic substrates in antennas, sensors, and power modules is expected to surge. Industry leaders are investing heavily in R&D to stay ahead in this competitive landscape.

6. Conclusion

Ceramic substrates represent a significant step forward in the evolution of 3C electronics. Their unmatched thermal, mechanical, and chemical properties position them as a superior alternative to traditional metal substrates. By addressing the challenges of heat management, weight, and durability, ceramics are transforming how electronic devices are designed and manufactured.

Looking ahead, the integration of ceramic substrates in 3C electronics will only accelerate, driven by technological advancements and market demand. Companies like Advanced Ceramic Materials (ACM) are at the forefront of developing cutting-edge ceramic solutions, further enhancing the material’s potential in the industry. As these innovations continue to evolve, ceramic substrates will play a pivotal role in shaping the future of electronics.

{{item.content}}

LEVE A REPLY

{{item.children[0].content}}

{{item.content}}

LEAVE A REPLY

SUBSCRIBE OUR NEWSLETTER

- An Overview of Nozzle Materials: Including ZSBN and Other Advanced Options

- Introduction to Magnesium Oxide Stabilized Zirconia Ceramics

- Silicon Nitride Bearing Balls: The 4000 MPa Solution for Aerospace Applications

- Boron Carbide (B10) for Effective Neutron Shielding in Nuclear Radiation

- Ceramic Materials for Surgical Devices: Al₂O₃ vs. ZrO₂