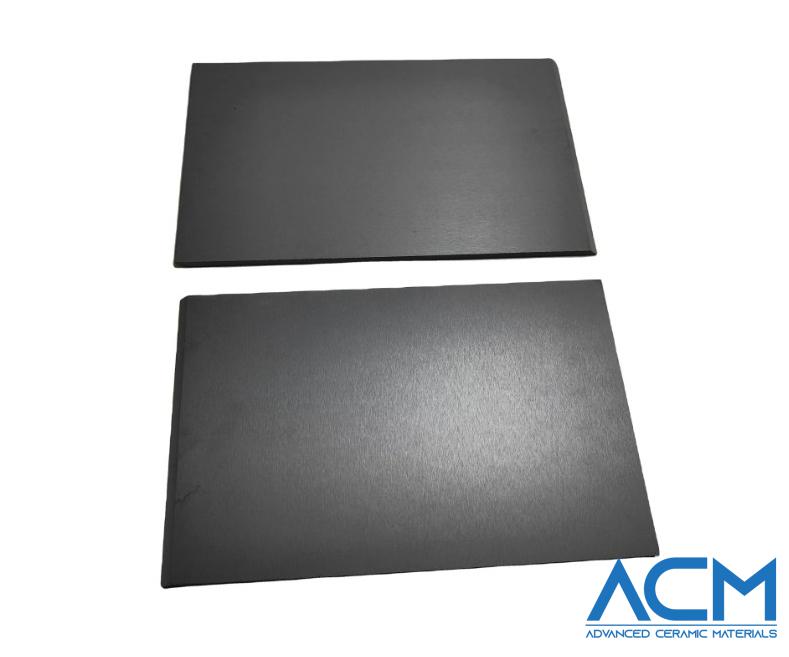

BC0913 (Discontinued) Boron Carbide Bulletproof Plate, B4C

- Catalog No. BC0913

- Molecular Formula B4C

- Appearance Black

- Melting Point 2445℃

- Density 2.1 to 2.7 g/cm3

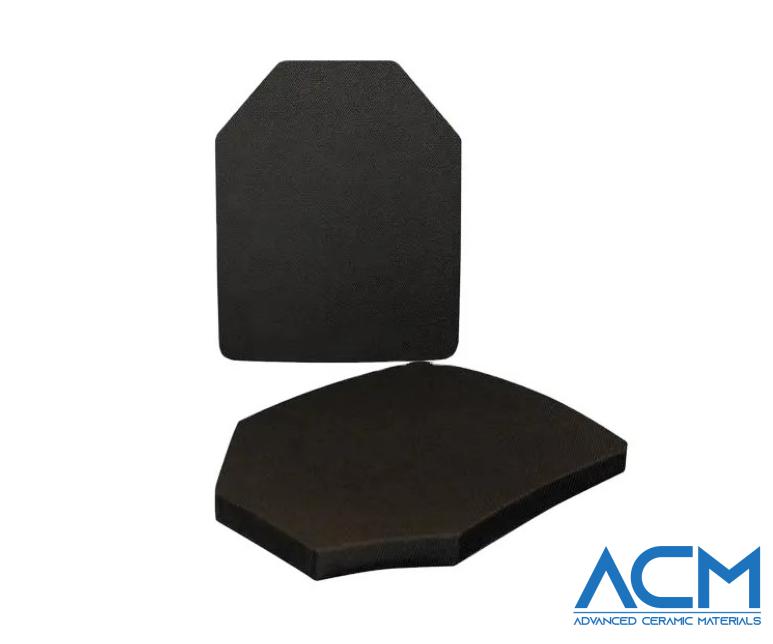

- Size 5mm-400mm Length of the side; 5mm-20mm Thick

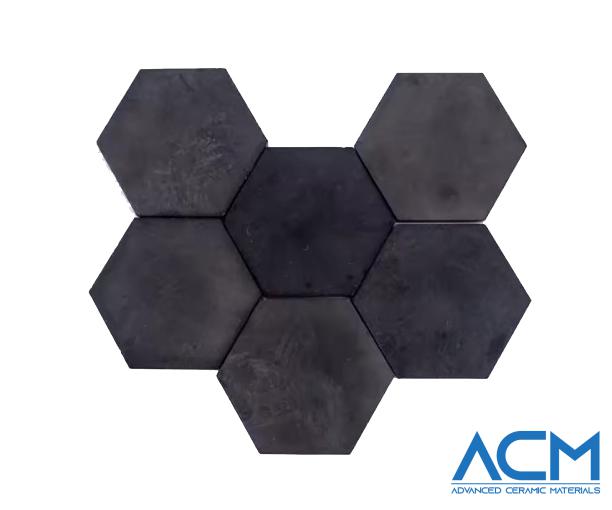

- Shape Square, disc, hexagonal

BC0913 (Discontinued) Boron Carbide Bulletproof Plate, B4C

Description

Advanced Ceramic Materials (ACM) offers high-quality Boron Carbide Bulletproof Plates, known for their exceptional hardness and strength. Boron Carbide (B4C) is a tough ceramic material, discovered in 1899, with a Mohs hardness of about 9.49, making it the third hardest material known after diamond and cubic boron nitride. This remarkable hardness and strength make boron carbide an ideal material for use in industries where wear resistance and abrasion resistance are crucial. Boron carbide is widely used as a protective coating and in manufacturing abrasive materials.

Specifications

| Property | Value |

|---|---|

| Molecular Formula | B4C |

| Appearance | Black |

| Melting Point | 2445 ℃ |

| Density | 2.1 to 2.7 g/cm³ |

| Size | 5mm-400mm (Length of the side), 5mm-20mm (Thickness) |

| Shape | Square, disc, hexagonal |

Key Features and Benefits

- Exceptional Hardness: Mohs hardness of 9.49, third hardest material after diamond and cubic boron nitride.

- Lightweight: Despite its high hardness and strength, boron carbide is lightweight, making it ideal for personal and vehicle armor.

- Ballistic Protection: Provides superior protection against ballistic threats while remaining lightweight.

- Wear Resistance: High wear and abrasion resistance, suitable for various industrial applications.

Technical Data

| Property | Value |

|---|---|

| Mohs Hardness | 9.49 |

| Density | 2.1 to 2.7 g/cm³ |

| Melting Point | 2445 ℃ |

| Thermal Conductivity | 30 W/mK |

| Fracture Toughness | 3.5 MPa·m1/2 |

| Flexural Strength | 400 MPa |

Applications

Boron Carbide Bulletproof Plates are used in various military and industrial applications:

- Military Protection: Essential for heavy armor protection in aircraft, tanks, ships, and other advanced physical protection needs.

- Personal Armor: Used by military personnel such as Army Security, Special Forces, Officers, Police, and Soldiers for reliable and effective protection.

- Industrial Use: Ideal for use in industries requiring high wear and abrasion resistance.

Advanced Armor Solutions

- Shock Absorption: Designed to absorb the kinetic energy of a bullet by engulfing the projectile, eliminating ricochet.

- Durable Materials: Combines UHMWPE molding technique with super-strong Boron Carbide ceramic for maximum durability and protection.

- Lightweight Design: Maintains a lightweight structure for improved mobility and reduced strain on the body.

- Fragment Containment: Special polyurethane coating ensures ceramic fragments remain contained, providing additional shock absorption.

- Multi-Curve Design: Mimics the human body with 3D multi-curved design, enhancing comfort, mobility, and weight distribution.

Packaging and Quality Assurance

ACM’s Boron Carbide Bulletproof Plates are carefully handled to minimize damage during storage and transportation, ensuring the products remain in their original high-quality condition.

Frequently Asked Questions (FAQs)

-

What is the maximum operating temperature for Boron Carbide plates?

- Our Boron Carbide plates can withstand temperatures up to 2445℃.

-

Do you offer custom sizes and shapes?

- Yes, we offer custom sizes and shapes to meet specific requirements. Please contact us for more details.

-

What are the typical applications for Boron Carbide Bulletproof Plates?

- Boron Carbide plates are used in military protection, personal armor, and industrial applications requiring high wear resistance.

Discover More

- Other Boron Carbide Products: Explore our range of boron carbide products.

- Latest Post: Read our latest article on Boron Carbide Applications.

- Contact Us: Get in touch or request a quote for more information.

-

Attachment (Optional)

No file chosen