SM6133 Silica Insulation Brick

- Catalog No. SM6133

- Material Si2O3

- Apparent Density 2.32 g/cm3

- Content Si2O3: 95%

- Max Working Temp. 1650 ℃

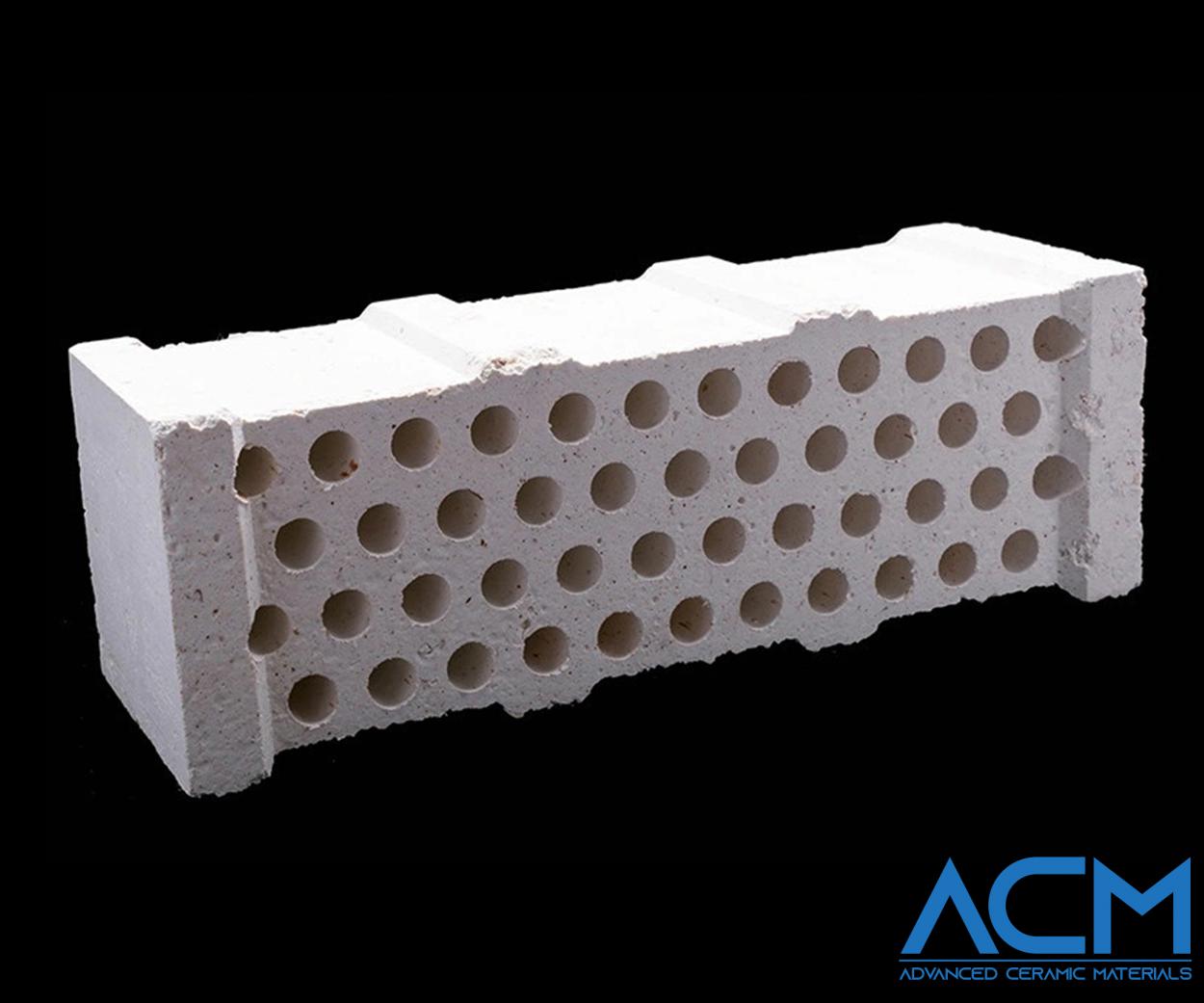

SM6133 Silica Insulation Brick

Silica Insulation Brick Overview

Silica Insulation Brick is a lightweight refractory brick primarily composed of silica (SiO₂). Designed for high-temperature environments such as furnaces, kilns, and ovens, these bricks provide excellent thermal insulation. They are characterized by low thermal conductivity, high temperature resistance, and good thermal shock resistance, making them ideal for applications requiring both effective insulation and heat stability.

Silica Insulation Brick Specifications

|

Item |

KY-0.8 |

KY-1.0 |

KY-1.1 |

KY-1.15 |

KY-1.2 |

|

SiO2 % |

≥88 |

≥91 |

≥91 |

≥91 |

≥91 |

|

Bulk Density g/cm3 |

≤0.85 |

≤1.00 |

≤1.10 |

≤1.15 |

≤1.20 |

|

Cold Crushing Strength Mpa |

≥1.0 |

≥2.0 |

≥3.0 |

≥5.0 |

≥5.0 |

|

Thermal Conductivity (W/M·K) 350℃ |

0.55 |

0.55 |

0.60 |

0.65 |

0.70 |

|

Permanent Linear Change On Reheating (%) 1450℃*2h |

0~+0.5 |

0~+0.5 |

0~+0.5 |

0~+0.5 |

0~+0.5 |

|

0.2Mpa Refractoriness Under Load T0.6℃ |

≥1400 |

≥1420 |

≥1460 |

≥1500 |

≥1520 |

|

20~1000℃ Thermal Expansion 10-6/℃ |

1.3 |

1.3 |

1.3 |

1.3 |

1.3 |

Silica Insulation Brick Applications

- Coke Ovens: Lining for regenerators and checker bricks.

- Glass Furnaces: Hot face and backing layers of glass melting tanks.

- Ceramic Kilns: Lining for kiln furniture and high-temperature areas.

Silica Insulation Brick Packaging

Silica Insulation Bricks are typically packaged in wooden crates or pallets to ensure safe handling and transportation. Each crate or pallet is securely wrapped and labeled with the product specifications and quantity to prevent damage during shipping. Custom packaging options are available upon request to meet specific customer needs.

Frequently Asked Questions (FAQs)

1. What are the main advantages of Silica Insulation Brick?

- Silica Insulation Bricks offer low thermal conductivity, high resistance to thermal shock, and excellent heat stability. These properties make them ideal for high-temperature insulation applications.

2. What is the maximum service temperature of Silica Insulation Bricks?

- The maximum service temperature can vary depending on the specific product, with some bricks capable of withstanding temperatures up to 1520°C.

3. How is the thermal conductivity of Silica Insulation Brick measured?

- Thermal conductivity is measured in W/m·K and indicates how effectively the brick insulates against heat. Lower values represent better insulation properties.

4. Can Silica Insulation Bricks be used in chemical environments?

- Yes, they are suitable for environments where both high temperatures and chemical stability are required. However, for highly corrosive environments, additional assessments may be necessary.

5. How should Silica Insulation Bricks be stored before use?

- They should be stored in a dry, clean area to prevent any moisture absorption or contamination. Proper storage helps maintain the brick’s performance and longevity.

-

Attachment (Optional)

No file chosen